- Male

- Followed by 0 people

Recent Updates

- Dispensing, Coating, and Their Applications with Plasma Cleaning

Dispensing and coating processes are widely used in manufacturing, while plasma cleaning serves as a critical pre-treatment step, significantly enhancing their quality and reliability. Plasma cleaning creates an ideal substrate environment for dispensing and coating by activating surfaces, removing contaminants, and increasing surface energy.

Key Applications of Plasma Cleaning for Dispensing and Coating:

1.Improved Adhesion Strength and Reliability:

Problem: Substrate surfaces (e.g., plastic, metal, ceramic, glass) may have trace organic contaminants, oils, oxides, or release agents that hinder effective wetting and chemical bonding of adhesives/coatings. This leads to weak bonds, cold joints, coating delamination, and interfacial failure.

Plasma Action: High-energy particles in the plasma bombard the surface, effectively removing microscopic contaminants (organic and inorganic). Simultaneously, plasma activates the surface, introducing polar functional groups (e.g., hydroxyl, carboxyl, amino groups), significantly increasing surface energy.

https://secondintelligent.com/industry-news/dispensing-coating-their-applications-with-plasma-cleaning/Dispensing, Coating, and Their Applications with Plasma Cleaning Dispensing and coating processes are widely used in manufacturing, while plasma cleaning serves as a critical pre-treatment step, significantly enhancing their quality and reliability. Plasma cleaning creates an ideal substrate environment for dispensing and coating by activating surfaces, removing contaminants, and increasing surface energy. Key Applications of Plasma Cleaning for Dispensing and Coating: 1.Improved Adhesion Strength and Reliability: Problem: Substrate surfaces (e.g., plastic, metal, ceramic, glass) may have trace organic contaminants, oils, oxides, or release agents that hinder effective wetting and chemical bonding of adhesives/coatings. This leads to weak bonds, cold joints, coating delamination, and interfacial failure. Plasma Action: High-energy particles in the plasma bombard the surface, effectively removing microscopic contaminants (organic and inorganic). Simultaneously, plasma activates the surface, introducing polar functional groups (e.g., hydroxyl, carboxyl, amino groups), significantly increasing surface energy. https://secondintelligent.com/industry-news/dispensing-coating-their-applications-with-plasma-cleaning/0 Comments 0 Shares - How to apply underfill adhesive glue dispensing to the bottom of chips on a PCB board?

Underfilling chips on PCB boards is a precision process primarily used for chips with ball grid arrays on their undersides, such as BGAs (Ball Grid Arrays) and CSPs (Chip-Scale Packages).

Below, I will explain the procedure in detail, covering its purpose, materials, equipment, steps, and precautions.

1.Why Use Underfill?

The primary purpose is to enhance the mechanical strength and long-term reliability of chips, especially in products operating under harsh conditions.

SMT automatic glue dispenser SEC-DH600L

Second Intelligent high precision smt automatic glue dispenser machine apply epoxy resin to the bottom of the PCB board for underfill

Second Intelligent smt automatic glue dispenser automation SEC-DH600L has the following advantages:

● CCD visual programming precise positioning, visual correction, improve programming efficiency and dispensing accuracy;

● Chinese and English operating system, the software interface layout is clear, the operation is simple, easy to learn and understand;

● Support visual inspection, integrated control of dispensing and visual inspection, multi-purpose machine, effective control of dispensing yield;

● It can be equipped with a lin e laser scanner for 3D path guidance and flexible dispensing;

● The software can support a variety of dispensing systems and functional module applications, such as automatic needle alignment, automatic

height measurement, dispensing weighing compensation, five-axis linkage and other functions, which can effectively overcome the difficulties of various dispensing processes and help improve quality;How to apply underfill adhesive glue dispensing to the bottom of chips on a PCB board? Underfilling chips on PCB boards is a precision process primarily used for chips with ball grid arrays on their undersides, such as BGAs (Ball Grid Arrays) and CSPs (Chip-Scale Packages). Below, I will explain the procedure in detail, covering its purpose, materials, equipment, steps, and precautions. 1.Why Use Underfill? The primary purpose is to enhance the mechanical strength and long-term reliability of chips, especially in products operating under harsh conditions. SMT automatic glue dispenser SEC-DH600L Second Intelligent high precision smt automatic glue dispenser machine apply epoxy resin to the bottom of the PCB board for underfill Second Intelligent smt automatic glue dispenser automation SEC-DH600L has the following advantages: ● CCD visual programming precise positioning, visual correction, improve programming efficiency and dispensing accuracy; ● Chinese and English operating system, the software interface layout is clear, the operation is simple, easy to learn and understand; ● Support visual inspection, integrated control of dispensing and visual inspection, multi-purpose machine, effective control of dispensing yield; ● It can be equipped with a lin e laser scanner for 3D path guidance and flexible dispensing; ● The software can support a variety of dispensing systems and functional module applications, such as automatic needle alignment, automatic height measurement, dispensing weighing compensation, five-axis linkage and other functions, which can effectively overcome the difficulties of various dispensing processes and help improve quality;0 Comments 0 Shares - Micro-dispensing application case: How to achieve uniform and precise adhesive coating of sealing resin on connectors?

Achieving uniform and precise adhesive coating of sealing resin on connectors requires high-precision dispensing technology, equipment selection, and process optimization. This, combined with the connector’s structural characteristics and sealing requirements, necessitates breakthroughs in core technologies and system collaboration to achieve precise control of adhesive quantity and consistent coating. The following details the implementation path from four dimensions: technical solutions, core equipment, process optimization, and application effects:

Fully Second Intelligent Equipment Co., Ltd Automatic 3-Axis Potting Machine SEC-S3030B & SEC-S3030C

The work of the glue potting machine mainly depends on air pressure control. Through the air pressure device, the glue is pressed out by pressure, and the size of the glue is controlled by the pump body. At the same time, the robotic arm is responsible for controlling the moving position of the glue discharge to achieve fully automated operation. This automated operation not only solves the problem of low labor efficiency, but also greatly improves the quality of production.

b.High-Efficiency Production: Dispensing speed can reach 5-6 seconds/cycle. The daily output of a single machine is equivalent to 4-6 workers, while reducing inconsistent glue dosage caused by human operation and improving connector sealing yield.

Micro-dispensing application case: How to achieve uniform and precise adhesive coating of sealing resin on connectors? Achieving uniform and precise adhesive coating of sealing resin on connectors requires high-precision dispensing technology, equipment selection, and process optimization. This, combined with the connector’s structural characteristics and sealing requirements, necessitates breakthroughs in core technologies and system collaboration to achieve precise control of adhesive quantity and consistent coating. The following details the implementation path from four dimensions: technical solutions, core equipment, process optimization, and application effects: Fully Second Intelligent Equipment Co., Ltd Automatic 3-Axis Potting Machine SEC-S3030B & SEC-S3030C The work of the glue potting machine mainly depends on air pressure control. Through the air pressure device, the glue is pressed out by pressure, and the size of the glue is controlled by the pump body. At the same time, the robotic arm is responsible for controlling the moving position of the glue discharge to achieve fully automated operation. This automated operation not only solves the problem of low labor efficiency, but also greatly improves the quality of production. b.High-Efficiency Production: Dispensing speed can reach 5-6 seconds/cycle. The daily output of a single machine is equivalent to 4-6 workers, while reducing inconsistent glue dosage caused by human operation and improving connector sealing yield.0 Comments 0 Shares - How to apply underfill adhesive glue dispensing to the bottom of chips on a PCB board?

Underfilling chips on PCB boards is a precision process primarily used for chips with ball grid arrays on their undersides, such as BGAs (Ball Grid Arrays) and CSPs (Chip-Scale Packages).

Below, I will explain the procedure in detail, covering its purpose, materials, equipment, steps, and precautions.

1.Why Use Underfill?

The primary purpose is to enhance the mechanical strength and long-term reliability of chips, especially in products operating under harsh conditions.

1.Resist Mechanical Stress:Prevents solder joint cracking caused by PCB bending, vibration, or impact. Underfill is critical for portable devices like smartphones during drops.

Second Intelligent high precision smt automatic glue dispenser machine apply epoxy resin to the bottom of the PCB board for underfill

Second Intelligent smt automatic glue dispenser automation SEC-DH600L has the following advantages:

● CCD visual programming precise positioning, visual correction, improve programming efficiency and dispensing accuracy;

● Chinese and English operating system, the software interface layout is clear, the operation is simple, easy to learn and understand;

● Support visual inspection, integrated control of dispensing and visual inspection, multi-purpose machine, effective control of dispensing yield;

● It can be equipped with a lin e laser scanner for 3D path guidance and flexible dispensing;

● The software can support a variety of dispensing systems and functional module applications, such as automatic needle alignment, automatic

height measurement, dispensing weighing compensation, five-axis linkage and other functions, which can effectively overcome the difficulties of various dispensing processes and help improve quality;How to apply underfill adhesive glue dispensing to the bottom of chips on a PCB board? Underfilling chips on PCB boards is a precision process primarily used for chips with ball grid arrays on their undersides, such as BGAs (Ball Grid Arrays) and CSPs (Chip-Scale Packages). Below, I will explain the procedure in detail, covering its purpose, materials, equipment, steps, and precautions. 1.Why Use Underfill? The primary purpose is to enhance the mechanical strength and long-term reliability of chips, especially in products operating under harsh conditions. 1.Resist Mechanical Stress:Prevents solder joint cracking caused by PCB bending, vibration, or impact. Underfill is critical for portable devices like smartphones during drops. Second Intelligent high precision smt automatic glue dispenser machine apply epoxy resin to the bottom of the PCB board for underfill Second Intelligent smt automatic glue dispenser automation SEC-DH600L has the following advantages: ● CCD visual programming precise positioning, visual correction, improve programming efficiency and dispensing accuracy; ● Chinese and English operating system, the software interface layout is clear, the operation is simple, easy to learn and understand; ● Support visual inspection, integrated control of dispensing and visual inspection, multi-purpose machine, effective control of dispensing yield; ● It can be equipped with a lin e laser scanner for 3D path guidance and flexible dispensing; ● The software can support a variety of dispensing systems and functional module applications, such as automatic needle alignment, automatic height measurement, dispensing weighing compensation, five-axis linkage and other functions, which can effectively overcome the difficulties of various dispensing processes and help improve quality;0 Comments 0 Shares - Common problems and solutions in the dispensing process : a must-read for efficient production

In precision manufacturing fields such as electronics, automotive, and medical, the stability of the dispensing process directly determines product quality. However, various problems inevitably arise during the dispensing process due to factors such as adhesive characteristics, operating procedures, and equipment maintenance. This article summarizes six common problems in the dispensing process and provides professional solutions based on the structural features and technological advantages of Second Intelligent dispensing machines , helping companies quickly troubleshoot and improve production efficiency.

1.Abnormal dispensing amount (too much/too little ) :

Problem description : Excessive glue dispensing volume ( the volume of glue output in a single dispensing operation ) causes glue to overflow and contaminate the product; insufficient glue dispensing volume results in weak adhesion and product malfunction.

Main reasons: improper pressure settings, incorrect dispensing time parameters, mismatch between needle selection and glue viscosity, and unstable back pressure of the glue supply system.

Solution :

● Parameter calibration: Adjust the dispensing pressure according to the viscosity of the adhesive (for example, the pressure needs to be increased for high-viscosity silicone), and simultaneously fine-tune the dispensing time. It is recommended to use the principle of “small amplitude multiple tests” to determine the optimal value.

Second Intelligent was established in 2005 with base in Shenzhen and is recognized as China’s leading manufacturer of providing solutions to fluid dispensing challenges, services customers across various industrial sectors with unparalleled technical expertise.

Second Intelligent Equipment have played an important role in the research, development, manufacturing, pre-sales and after-sales services of fluid dispensing, coating and potting solutions, and will always strive to create world-class products that are recognized by our customers, using our top-notch technology to achieve the highest level of quality.

Common problems and solutions in the dispensing process : a must-read for efficient production In precision manufacturing fields such as electronics, automotive, and medical, the stability of the dispensing process directly determines product quality. However, various problems inevitably arise during the dispensing process due to factors such as adhesive characteristics, operating procedures, and equipment maintenance. This article summarizes six common problems in the dispensing process and provides professional solutions based on the structural features and technological advantages of Second Intelligent dispensing machines , helping companies quickly troubleshoot and improve production efficiency. 1.Abnormal dispensing amount (too much/too little ) : Problem description : Excessive glue dispensing volume ( the volume of glue output in a single dispensing operation ) causes glue to overflow and contaminate the product; insufficient glue dispensing volume results in weak adhesion and product malfunction. Main reasons: improper pressure settings, incorrect dispensing time parameters, mismatch between needle selection and glue viscosity, and unstable back pressure of the glue supply system. Solution : ● Parameter calibration: Adjust the dispensing pressure according to the viscosity of the adhesive (for example, the pressure needs to be increased for high-viscosity silicone), and simultaneously fine-tune the dispensing time. It is recommended to use the principle of “small amplitude multiple tests” to determine the optimal value. Second Intelligent was established in 2005 with base in Shenzhen and is recognized as China’s leading manufacturer of providing solutions to fluid dispensing challenges, services customers across various industrial sectors with unparalleled technical expertise. Second Intelligent Equipment have played an important role in the research, development, manufacturing, pre-sales and after-sales services of fluid dispensing, coating and potting solutions, and will always strive to create world-class products that are recognized by our customers, using our top-notch technology to achieve the highest level of quality.0 Comments 0 Shares - Application of potting in the home appliances industry: Potting of Washing Machine Control Board / Computer Board?

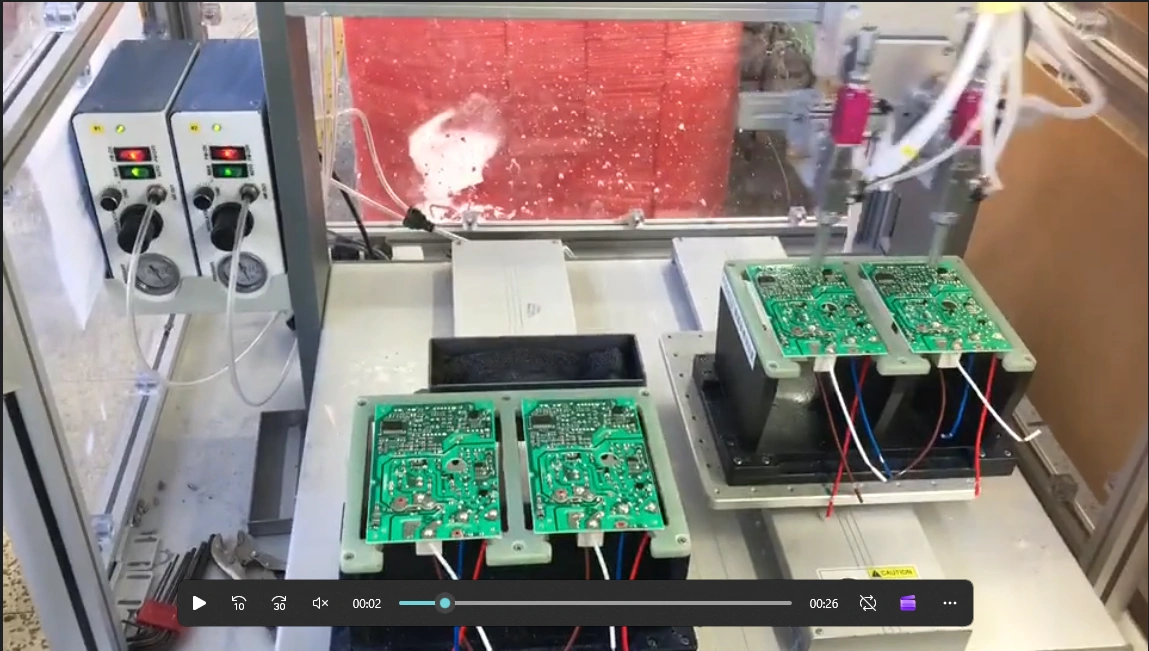

The encapsulation of washing machine control boards (computer boards) is one of the most typical applications of automated potting machine, directly impacting the reliability, safety, and lifespan of the washing machine.

Below, I will elaborate on the application of Automatic Glue Potting Machine in the encapsulation of washing machine control boards from the perspectives of “why encapsulation is needed,” “what adhesive to use,” “how to perform encapsulation,” and “the benefits of encapsulation.”

Ι.Why is potting necessary for washing machine control boards? (Necessity) Washing machines operate in extremely harsh environments, posing multiple threats to the control board:

1.Water and moisture protection: The internal humidity of washing machines is extremely high, especially in top-loading washing machines. Condensation and accidental splashes can cause short circuits and component corrosion.

2.Corrosion protection: Detergents, fabric softeners, bleach, and other chemicals are corrosive; their vapors can corrode circuit boards and component leads.

3.Shock and loosening prevention: Washing machines generate severe vibrations during the spin-drying process. Prolonged vibration can lead to solder joint cracking and component loosening.

4.Heat dissipation and insulation:Power devices on the control board (such as SCRs) generate heat during operation. Potting compound helps dissipate heat and provides excellent electrical insulation, preventing high-voltage creepage.

Second Intelligent has played an important role in theresearch, development, manufacturing, pre-sales and after-sales services of fluid dispensing robot, potting and coating solutions which range from various types of automatic fluid dispensing, potting, two-component potting machines and coating machines with desktop, free-standing, inline or cobot combined systems, and widely used in global electrical, electronics, home appliances, automobile, telecom, pharmaceutical, automotive electronics, semiconductor, aerospace, LED and more.

Application of potting in the home appliances industry: Potting of Washing Machine Control Board / Computer Board? The encapsulation of washing machine control boards (computer boards) is one of the most typical applications of automated potting machine, directly impacting the reliability, safety, and lifespan of the washing machine. Below, I will elaborate on the application of Automatic Glue Potting Machine in the encapsulation of washing machine control boards from the perspectives of “why encapsulation is needed,” “what adhesive to use,” “how to perform encapsulation,” and “the benefits of encapsulation.” Ι.Why is potting necessary for washing machine control boards? (Necessity) Washing machines operate in extremely harsh environments, posing multiple threats to the control board: 1.Water and moisture protection: The internal humidity of washing machines is extremely high, especially in top-loading washing machines. Condensation and accidental splashes can cause short circuits and component corrosion. 2.Corrosion protection: Detergents, fabric softeners, bleach, and other chemicals are corrosive; their vapors can corrode circuit boards and component leads. 3.Shock and loosening prevention: Washing machines generate severe vibrations during the spin-drying process. Prolonged vibration can lead to solder joint cracking and component loosening. 4.Heat dissipation and insulation:Power devices on the control board (such as SCRs) generate heat during operation. Potting compound helps dissipate heat and provides excellent electrical insulation, preventing high-voltage creepage. Second Intelligent has played an important role in theresearch, development, manufacturing, pre-sales and after-sales services of fluid dispensing robot, potting and coating solutions which range from various types of automatic fluid dispensing, potting, two-component potting machines and coating machines with desktop, free-standing, inline or cobot combined systems, and widely used in global electrical, electronics, home appliances, automobile, telecom, pharmaceutical, automotive electronics, semiconductor, aerospace, LED and more.0 Comments 0 Shares1 - IGBT Industry Equipment Vacuum glue potting Solutions: How to achieve uniform potting?

As the core power device in power electronic equipment, the packaging reliability of IGBTs (Insulated Gate Bipolar Transistors) directly determines the lifespan and performance of the entire converter, frequency converter, or new energy equipment. Vacuum potting is a crucial step in the current IGBT module packaging process.

Below, I will provide you with a detailed analysis of application cases of IGBT vacuum potting lines, covering process value, typical production line structure, specific application examples, key challenges, and trends:

Second Intelligent Equipment is recognized as China’s leading manufacturer of providing solutions to fluid dispensing challenges, services customers across various industrial sectors with unparalleled technical expertise.IGBT Industry Equipment Vacuum glue potting Solutions: How to achieve uniform potting? As the core power device in power electronic equipment, the packaging reliability of IGBTs (Insulated Gate Bipolar Transistors) directly determines the lifespan and performance of the entire converter, frequency converter, or new energy equipment. Vacuum potting is a crucial step in the current IGBT module packaging process. Below, I will provide you with a detailed analysis of application cases of IGBT vacuum potting lines, covering process value, typical production line structure, specific application examples, key challenges, and trends: Second Intelligent Equipment is recognized as China’s leading manufacturer of providing solutions to fluid dispensing challenges, services customers across various industrial sectors with unparalleled technical expertise.0 Comments 0 Shares1 - adhesive dispensing & potting machines in new energy power batteries

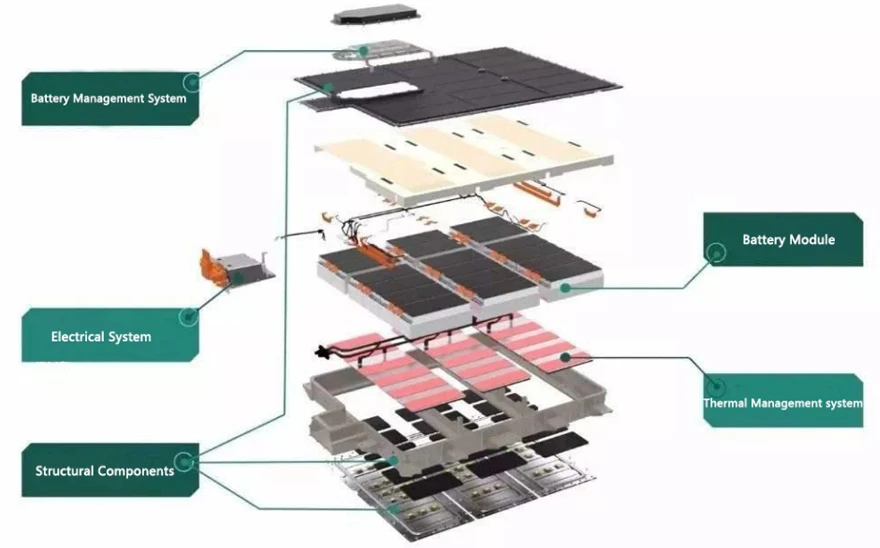

Power batteries serve as the engine equivalent for gasoline vehicles and the primary power source for new energy vehicles. Power battery modules are assembled by “packaging” individual cells. Power batteries are primarily categorized into battery packs, modules, and cells.

Within the power battery sector, dispensing machines play a crucial role in cell encapsulation and battery pack assembly processes.

Second Intelligent was established in 2005 with base in Shenzhen and is recognized as China’s leading manufacturer of providing solutions to fluid dispensing challenges, services customers across various industrial sectors with unparalleled technical expertise.

We have played an important role in the research, development, manufacturing, pre-sales and after-sales services of fluid dispensing, coating and potting solutions, and will always strive to create world-class products that are recognized by our customers, using our top-notch technology to achieve the highest level of quality.

adhesive dispensing & potting machines in new energy power batteries Power batteries serve as the engine equivalent for gasoline vehicles and the primary power source for new energy vehicles. Power battery modules are assembled by “packaging” individual cells. Power batteries are primarily categorized into battery packs, modules, and cells. Within the power battery sector, dispensing machines play a crucial role in cell encapsulation and battery pack assembly processes. Second Intelligent was established in 2005 with base in Shenzhen and is recognized as China’s leading manufacturer of providing solutions to fluid dispensing challenges, services customers across various industrial sectors with unparalleled technical expertise. We have played an important role in the research, development, manufacturing, pre-sales and after-sales services of fluid dispensing, coating and potting solutions, and will always strive to create world-class products that are recognized by our customers, using our top-notch technology to achieve the highest level of quality.0 Comments 0 Shares