In today’s world of high-efficiency HVAC systems, microchannel coil technology has emerged as a cutting-edge solution, offering major improvements in thermal performance, energy savings, and equipment durability. Whether you're designing systems for commercial buildings, industrial cooling, or residential applications, microchannel coils are changing the game.

How Microchannel Coils Work

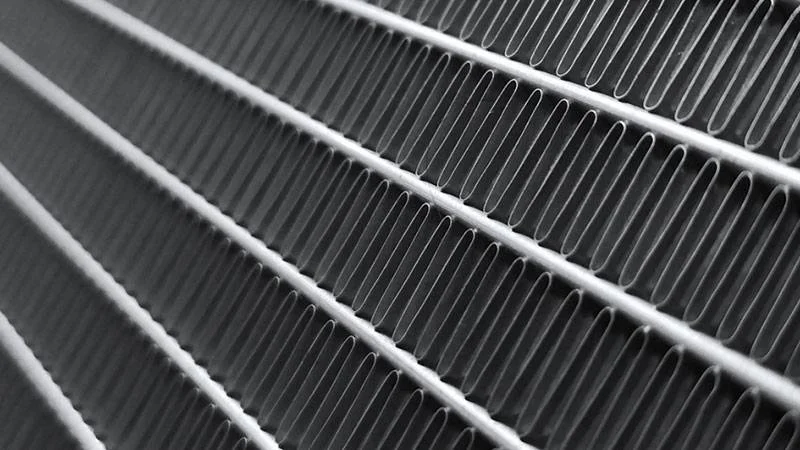

Unlike traditional finned-tube heat exchangers, microchannel coils feature a flat-tube design with multiple small, parallel channels. These tubes are surrounded by aluminum fins and encased in a compact coil body. The entire structure is made from aluminum, offering advantages in heat conductivity, corrosion resistance, and weight reduction.

Three Key Areas of Heat Transfer Optimization

Microchannel coil performance is based on improvements across three heat transfer zones:

-

Air-side efficiency – Thin, densely packed fins increase the contact surface between air and metal, allowing faster heat absorption or rejection.

-

Fin-to-tube conduction – The flat-tube design ensures strong thermal connectivity between the fins and tubes, which reduces resistance and enhances heat conduction.

-

Refrigerant-side performance – Inside each flat tube, multi-port microchannels allow for even refrigerant distribution, minimizing pressure drops and maximizing thermal exchange.

Together, these design improvements can yield a 20–40% gain in system efficiency compared to older coil technologies.

Kaltra: Leading the Innovation Curve

Among the pioneers in this field, Kaltra offers high-performance microchannel coils designed for reliability and long-term use. Their coils are used in a wide range of applications, including:

-

Air-cooled chillers

-

HVAC rooftop units

-

Heat pumps

-

Data center cooling systems

Kaltra’s coils are precision-manufactured and surface-treated for maximum protection against corrosion, making them a smart choice for both indoor and outdoor environments.

Advantages Beyond Efficiency

The benefits of microchannel coils go beyond performance:

-

Lightweight and compact – Easier to install, transport, and integrate into system designs.

-

Lower refrigerant charge – Helps meet environmental regulations and reduces operating costs.

-

Fewer brazed joints – Improves system reliability and lowers the risk of refrigerant leaks.

-

Eco-friendly – 100% recyclable materials support sustainability goals.

Future-Proofing HVAC Systems

As regulatory requirements become more stringent and the demand for energy efficiency grows, microchannel coils are becoming the new industry standard. They offer the flexibility, durability, and performance required for modern system designs.

Conclusion: Smarter Engineering for Smarter HVAC

Whether you’re a design engineer, facility manager, or HVAC installer, investing in https://www.kaltra.com/microchannel-coils microchannel coil technology means equipping your systems for the future. With proven results in the field and consistent performance across a wide range of applications, microchannel coils—especially from trusted names like Kaltra—are the clear choice for next-generation HVAC systems.