In modern web converting and slitting operations, the Differential Air Shaft is positioned at the heart of efficiency and roll quality. This advanced mechanical component enables multiple reels to be wound with consistent tension even when there are thickness variations in the web material or differences in reel diameters.

Traditional shafts can struggle with varying web tensions across lanes, often resulting in wrinkles, telescoping, or even reel breakage. The differential shaft resolves this by providing torque compensation through friction rings or ball-type mechanisms that allow each reel to rotate independently while maintaining uniform pressure. This feature is crucial for high-speed, multi-lane slitting processes found in industries such as flexible packaging, labeling, film processing, and paper manufacturing.

What makes the differential shaft particularly valuable is its adaptability. Regardless of the type of material—be it plastic film, paper, nonwoven fabric, or metal foil—this shaft ensures that each roll is wound properly, reducing waste and increasing the quality of finished goods. This contributes significantly to production yield and operational savings over time.

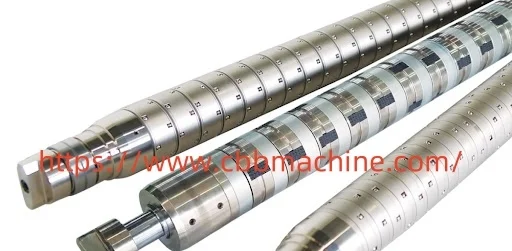

CBBMACHINE offers precision-engineered differential shafts that integrate seamlessly with a variety of slitting and rewinding machines. Each shaft is manufactured with tight tolerances, high-strength materials, and balanced designs that minimize vibration during high-speed operation. Their differential shafts are customizable to suit different core sizes, machine configurations, and torque requirements, making them a trusted choice in diverse converting environments.

Another key benefit is ease of maintenance. CBBMACHINE differential shafts are designed for fast assembly and disassembly, allowing operators to clean or replace friction elements without dismantling the entire shaft. This reduces machine downtime and boosts maintenance efficiency.

Energy efficiency is also improved. By allowing each reel to rotate at its own speed based on material tension, the drive system doesn’t need to compensate for minor imbalances across lanes. This lowers overall energy consumption and wear on other machine components.

CBBMACHINE’s dedication to product innovation ensures that each shaft not only meets the demands of current industry practices but also adapts to emerging production standards, including automation compatibility and lightweight design trends.

As manufacturers continue to seek solutions for higher speed, better quality, and reduced waste, the differential shaft remains a core element in achieving these goals. It's a quiet but powerful tool that helps make the difference between average production and excellence.

To explore technical specifications and product variations, visit www.cbbmachine.com