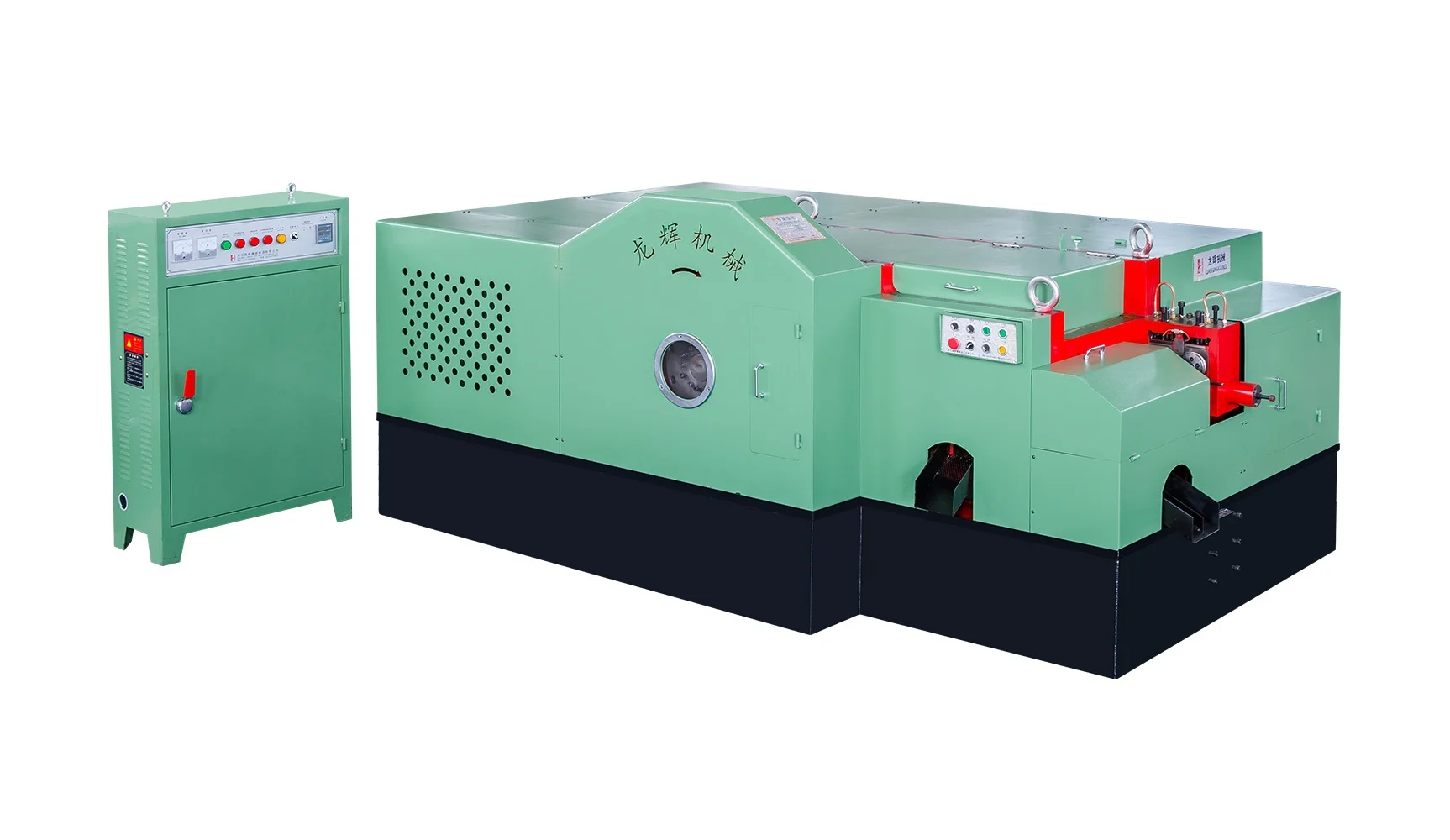

Multi-station cold heading forming machines are advanced industrial tools that play a crucial role in the manufacturing of metal parts. These machines are designed to shape metal by applying pressure without the need for heat, which is why they are termed "cold heading." The multi-station aspect refers to the capability of these machines to perform multiple operations in sequence, streamlining the production process. The primary function of a multi-station cold heading forming machine is to create fasteners, such as screws, bolts, and nails, from metal wire or rod. The process involves feeding a metal rod into the machine, where it is then subjected to a series of dies that progressively shape it into the desired form. Each station in a multi-station cold heading forming machine performs a specific task, such as cutting, forming, or threading, which contributes to the overall shaping of the metal. One of the key advantages of using multi-station cold heading forming machines is their efficiency. By combining several operations in one machine, manufacturers can reduce the need for multiple machines and manual handling, leading to a more streamlined and cost-effective production process. Additionally, these machines are known for their precision and consistency, ensuring that each part produced meets the highest quality standards. In the automotive, aerospace, and construction industries, multi-station cold heading forming machines are indispensable. They are used to produce a wide array of components that require high strength and durability. The machines' ability to handle high production volumes while maintaining precision makes them a preferred choice for mass manufacturing. In conclusion, multi-station cold heading forming machines are essential in modern manufacturing due to their efficiency, precision, and versatility. They have revolutionized the way metal parts are produced, offering a reliable solution for industries that demand high-quality components in large quantities.