In the packaging industry, precision and efficiency are crucial, and the role of a reliable Cap Mould cannot be overstated. A Cap Mould is an essential tool used in the manufacturing of plastic caps and closures, which are fundamental components in bottles, jars, and containers across various industries such as food, beverage, pharmaceuticals, and cosmetics.

One of the key advantages of a well-designed Cap Mould is its ability to produce caps with consistent quality and tight tolerances. This ensures that every cap fits perfectly on the container, providing an airtight seal that preserves product freshness and prevents leakage. High-quality Cap Moulds from reputable manufacturers, like those found on RDMould, combine advanced engineering with durable materials to achieve superior precision and longevity.

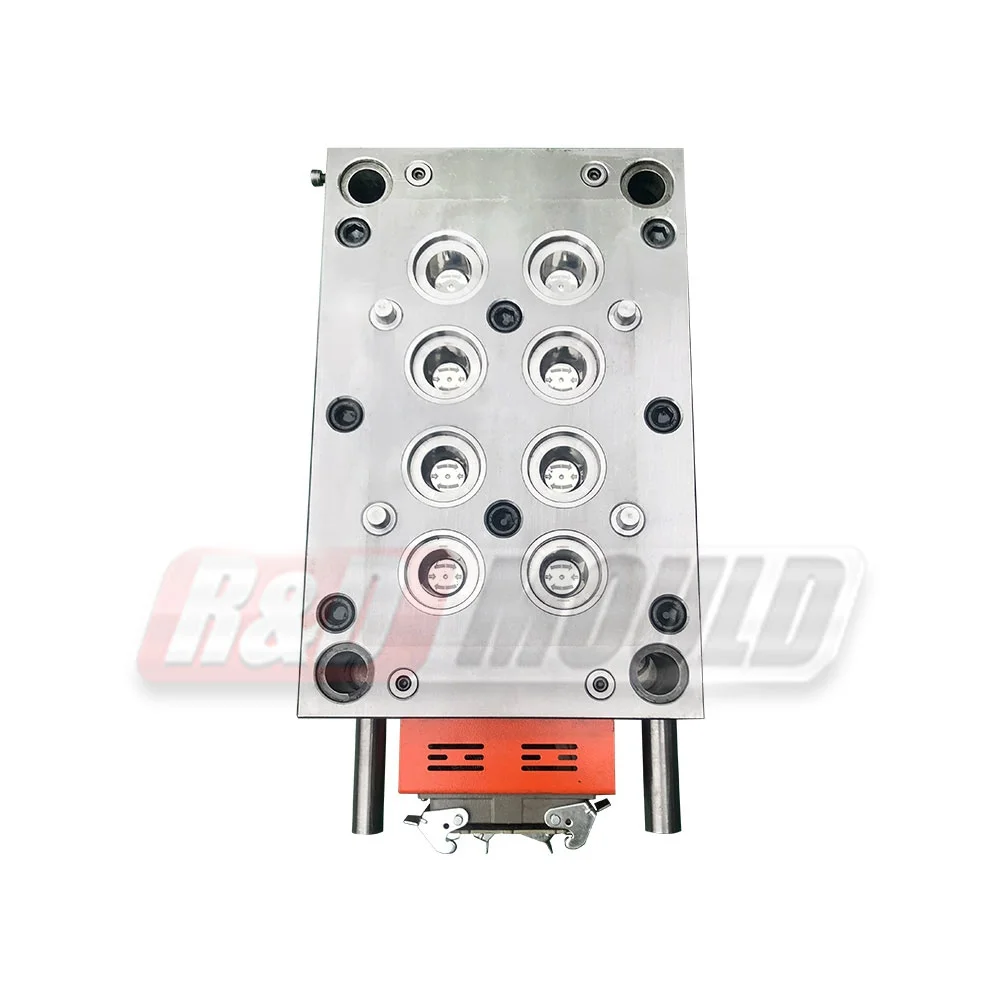

The production process using a Cap Mould involves injecting molten plastic into the mould cavity, where it cools and solidifies into the desired shape. The mould’s design impacts cycle time, material usage, and the final product’s aesthetics. Therefore, investing in a cutting-edge Cap Mould not only improves production efficiency but also enhances the visual appeal and functional performance of the caps.

Moreover, modern Cap Moulds often incorporate features such as easy maintenance, quick changeover capabilities, and customization options to meet diverse customer requirements. This flexibility makes Cap Moulds indispensable in today’s fast-paced manufacturing environment where multiple product lines are common.

In summary, a high-quality Cap Mould plays a pivotal role in the packaging supply chain. From ensuring the durability and reliability of closures to boosting production efficiency, the right Cap Mould can significantly impact the success of packaging manufacturers and their clients alike. For those seeking superior mould solutions, exploring options on platforms like RDMould offers access to advanced, tailor-made Cap Moulds designed for excellence.