At the core of modern mass manufacturing, especially for intricate electronics, medical devices, and automotive components, lies a critical enabler: the Precision Stamping Mold. Its defining characteristic isn't just an advantage; it's the foundational advantage: High Precision. This relentless focus on microscopic accuracy is what truly separates a Precision Stamping Mold from conventional tooling and unlocks the potential for next-generation products.

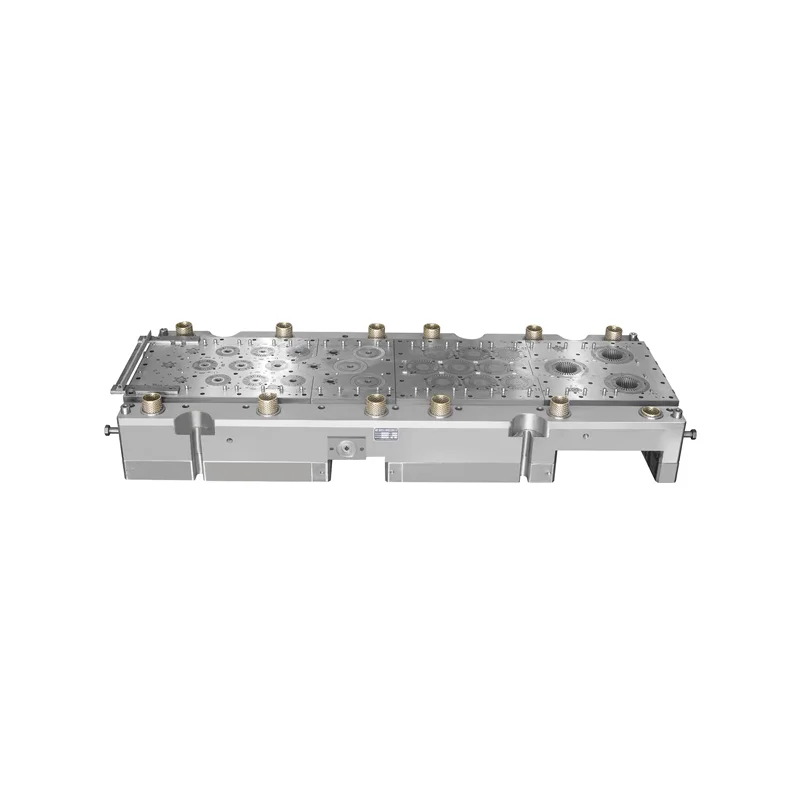

The most tangible evidence of this high precision is the ability to consistently produce parts with incredibly tight dimensional tolerances. We're talking about features held reliably within ±0.01mm to ±0.05mm, and sometimes even tighter. This isn't accidental; it's engineered into every facet of the Precision Stamping Mold. The mold base itself is machined to exacting standards. Critical components – the core and cavity inserts forming the part shape, the guide pillars and bushings ensuring perfect alignment with every stroke, and specialized wear-resistant镶件 (inserts) – are manufactured with extreme accuracy, often using state-of-the-art techniques like precision grinding, wire EDM, and laser machining.

This inherent precision within the mold translates directly to the stamped parts. It guarantees exceptional consistency and repeatability for every critical dimension across millions of cycles. Whether it's the exact contour of a micro-sim card tray, the precise location of tiny connector pins, the complex shape of a sensor bracket, or the critical bend angle of a conductive spring contact, the Precision Stamping Mold delivers unwavering accuracy. Part after part, hour after hour, the mold ensures that key features like hole positions, intricate geometries, and bend angles remain virtually identical. This level of consistency is non-negotiable for components where even micron-level deviations can cause assembly failures, electrical shorts, or performance degradation in the final product.

Achieving and maintaining this high precision requires more than just skilled craftsmanship. It demands meticulous design accounting for material behavior and springback, the use of ultra-stable high-performance tool steels, advanced heat treatments and surface coatings to combat wear, and incredibly robust guidance systems to eliminate deflection. Every element is optimized to preserve the designed geometry under the immense pressures and speeds of the stamping process.

Ultimately, the "Precision" in Precision Stamping Mold isn't just a label; it's the absolute commitment to microscopic accuracy and repeatability. It's this unwavering dedication to high precision that allows manufacturers to push the boundaries of miniaturization, complexity, and reliability, making these molds indispensable for producing the sophisticated components that power our world.