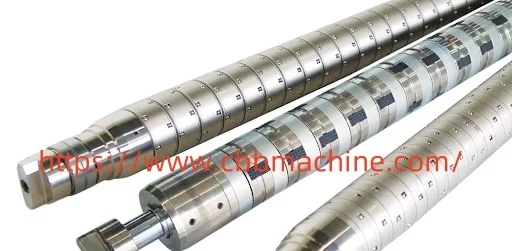

In modern web handling systems, the Differential Air Shaft plays a critical role in ensuring accurate tension control and independent roll adjustment across various materials such as film, paper, and foil. This specialized shaft uses air pressure and internal mechanical elements to allow each core on the shaft to rotate independently, making it an essential component in slitting and rewinding operations where uneven web thickness or tension variations often occur.

The primary advantage of using this type of shaft is its ability to compensate for material differences during high-speed operations. In a multi-core setup, without differential adjustment, outer rolls could tighten faster than inner ones, leading to tension imbalance, core breakage, or inconsistent winding. The Differential Air Shaft addresses these issues by providing automatic tension balance, leading to cleaner, safer, and more efficient winding results.

This technology is particularly valuable in industries such as flexible packaging, plastic film processing, label production, and battery material manufacturing. As production speeds increase and material diversity expands, traditional fixed shafts struggle to keep up with precise winding requirements. The differential design ensures that tension is equalized dynamically, regardless of the number of cores or the speed at which the machine operates.

Structurally, the shaft is composed of a central air-expansion tube, individual friction elements, and ball or spring mechanisms that provide resistance and torque distribution. The pressurized air inflates the core segments, locking them in place while allowing internal slippage when necessary. This slippage ensures that each roll is wound uniformly, even if the web tension or diameter varies from core to core.

For maintenance and durability, choosing high-quality materials for friction parts and precision-engineered seals is essential. Properly designed shafts reduce downtime, require minimal lubrication, and can withstand long-term use in heavy-duty environments. Furthermore, many modern systems now incorporate easy-to-replace friction pads and simplified air valves, improving operator efficiency and reducing service costs.

In addition to its mechanical benefits, using differential shafts enhances safety and material yield. Uniform winding reduces the risk of telescoping rolls or core damage, which minimizes waste. It also protects delicate materials like aluminum foil or multilayer films, which are more susceptible to damage from tension irregularities.

When integrating a differential shaft into a new or existing system, compatibility with machine specifications—such as torque range, core diameter, web width, and shaft length—must be carefully considered. Customization is often available, and it's worth collaborating with an experienced manufacturer to ensure the shaft’s performance aligns with the application’s unique needs.

Ultimately, the Differential Air Shaft contributes to better roll quality, higher machine uptime, and more consistent production output, especially in operations that handle diverse materials or require precision slitting.

To explore more about this solution and find customization options suitable for your application, please visit www.cbbmachine.com