Precision in web handling operations is often the difference between efficient production and costly downtime, and that's why the Differential Air Shaft plays a crucial role in modern converting systems.

This innovative device is designed specifically for winding and unwinding multiple rolls with varying tension requirements. In operations like slitting or laminating, where uniformity and tension consistency are essential, conventional air shafts often fall short. That's where differential air shafts step in—offering a more advanced and adaptable solution.

The key advantage of this shaft type lies in its ability to compensate for variations in roll diameter or tension during high-speed winding. Each core on the shaft is allowed to rotate independently, guided by a torque differential mechanism that ensures even tension distribution across all rolls. This is critical for industries like packaging, film, paper, and label production, where even the slightest tension deviation can result in wrinkles, telescoping, or material damage.

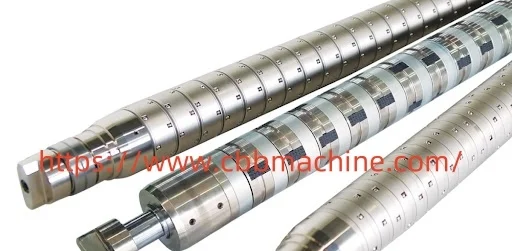

CBBMACHINE, a trusted leader in precision machinery and converting accessories, has mastered the art of producing high-performance shafts tailored to demanding industrial applications. Their differential air shafts are known for their reliability, superior torque control, and ability to handle multiple core widths with ease. Whether operating in harsh environments or high-speed production lines, their products are engineered to maintain perfect web alignment and minimize material waste.

Another important feature of CBBMACHINE's solution is its adaptability. These shafts can work seamlessly with different core sizes—like 3-inch or 6-inch cores—thanks to customizable adapters and friction ring mechanisms. The design ensures minimal operator intervention, which translates into faster setup times and reduced labor costs.

Durability is also a standout benefit. Made from high-strength aluminum alloys or steel, the shafts are corrosion-resistant and built to withstand long-term industrial wear and tear. Moreover, maintenance is easy, with replaceable components and minimal disassembly required, leading to lower overall lifecycle costs.

Automation and Industry 4.0 have heightened the need for smarter, more responsive machinery. The differential air shaft aligns with these advancements by offering consistent performance that reduces error, ensures product uniformity, and boosts throughput. It's no longer just a mechanical part—it's a productivity enabler.

If your production line is scaling, diversifying, or simply looking to improve output quality, investing in a reliable differential solution from CBBMACHINE could be the strategic upgrade you need.

To learn more about how these shafts work and how to choose the best one for your system, please visit https://www.cbbmachine.com/news/industry-news/differential-air-shafts-key-components-applications-benefits-and-more.html