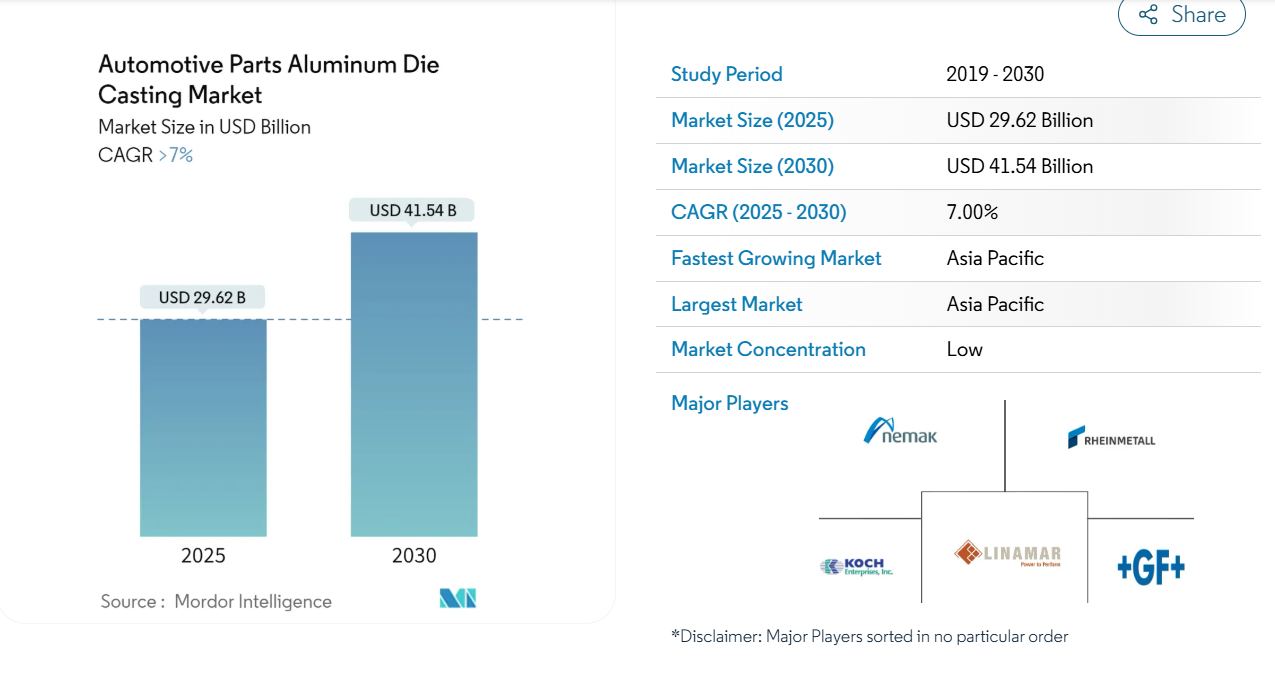

The Automotive Parts Aluminum Die Casting Market is set for robust growth, with its size projected to increase from USD 29.62 billion in 2025 to USD 41.54 billion by 2030, reflecting a compound annual growth rate (CAGR) of over 7%, according to market research data by Mordor Intelligence. This steady rise is a direct outcome of increasing demand for lightweight vehicles and the automotive industry's shift toward more sustainable and fuel-efficient solutions.

Market Drivers: The Shift Toward Lightweight Components

One of the key forces propelling the market is the rising demand for lightweight vehicles, especially in the passenger and electric vehicle segments. Automakers are increasingly turning to aluminum die casting for manufacturing parts like engine blocks, transmission housings, and structural components. Aluminum's superior strength-to-weight ratio and corrosion resistance make it an ideal material for enhancing vehicle efficiency without compromising on durability or safety.

The Role of Environmental Policies and Standards

Stringent environmental regulations and CAFE (Corporate Average Fuel Economy) standards across the United States, Europe, and other regions are also fueling this transition. These policies are designed to reduce vehicular emissions and improve fuel economy, prompting automakers to reduce vehicle weight wherever possible. This trend has led to a significant increase in the use of aluminum die casting technologies, which align well with regulatory objectives.

Explore our full library of Automotive Research industry Reports:

Technological Advancements in Die Casting

The market is also benefiting from technological advancements in the die casting process. Innovations such as vacuum die casting, automated production lines, and simulation-based design optimization are enhancing production quality, reducing waste, and improving operational efficiency. As the technology continues to evolve, manufacturers are better positioned to meet the rising demand from electric and hybrid vehicle production.

Outlook and Opportunities

As electric vehicles (EVs) continue to gain traction worldwide, the need for lighter, more efficient automotive parts will only grow stronger. This places aluminum die casting at the center of future automotive manufacturing strategies. Market players who invest in R&D, automation, and sustainable practices are expected to gain a competitive edge.

The automotive parts aluminum die casting industry stands at a transformative point, shaped by consumer demand, regulatory pressure, and evolving technology. The next five years are expected to witness significant innovation and expansion as the market adapts to the changing mobility landscape.

Related Reports:

aircraft electrical systems market