A through valve is a practical component in fluid systems, used to control the passage of liquids or gases. It allows the medium to flow directly through the valve while providing control over pressure and volume. The design is typically simple, which enables consistent performance and easy integration into different pipeline setups.

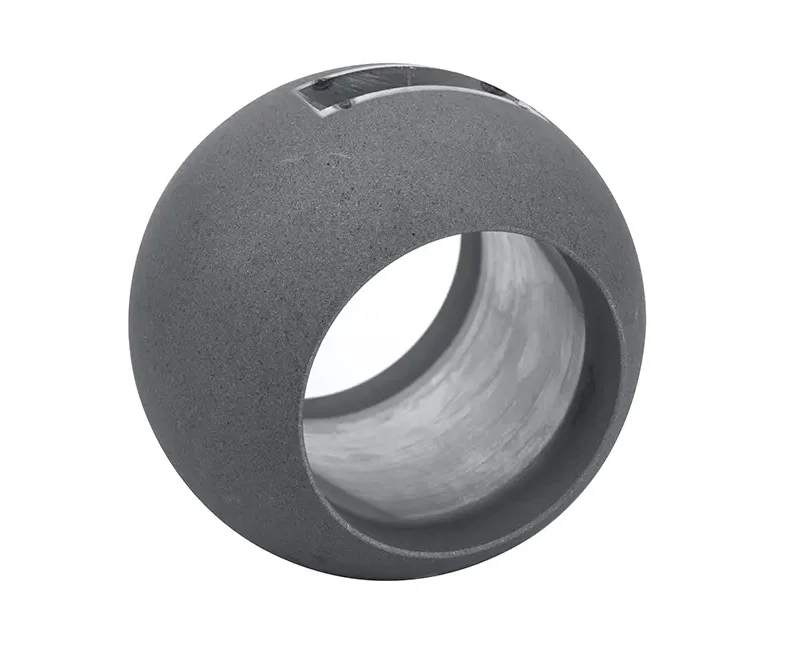

The internal structure of a through valve includes a valve body, a movable closure element, and a seat. This setup allows precise regulation of flow while minimizing turbulence and resistance. Operators can adjust the valve manually or rely on actuators for automated control in larger systems. This flexibility makes through valves suitable for many industrial applications, including water distribution, chemical transport, and heating networks.

Material selection is an important factor when installing a through valve. Metals like stainless steel or brass provide durability and resistance to corrosion, while specific plastics can handle chemical exposure. Correct installation and regular maintenance are key to ensuring the valve continues to function as intended. Tasks such as cleaning, lubrication, and checking for wear help extend its operational life.

In pipelines, through valves often work alongside other components, such as pumps and filters, to maintain efficient flow. They allow for adjustments without stopping the entire system, which is valuable in continuous processes. Their design ensures minimal pressure loss while providing sufficient control over fluid movement.

Through valves serve as reliable instruments for managing fluid flow. Understanding their construction, materials, and maintenance needs enables operators to use them effectively across various industrial and commercial applications. Their presence in a system ensures controlled, consistent, and adaptable flow management.

If you are interested in our products, please visit our official website:Zhejiang Boshi Valve Technology Co., Ltd.