In the realm of modern electronics, precision and efficiency are paramount. High speed stamping mold has emerged as a crucial technology that significantly enhances the production process of various electronic components, particularly in the manufacturing of motor laminations, electric motor stampings, and connectors. This article delves into the importance and applications of high speed stamping mold in these areas.

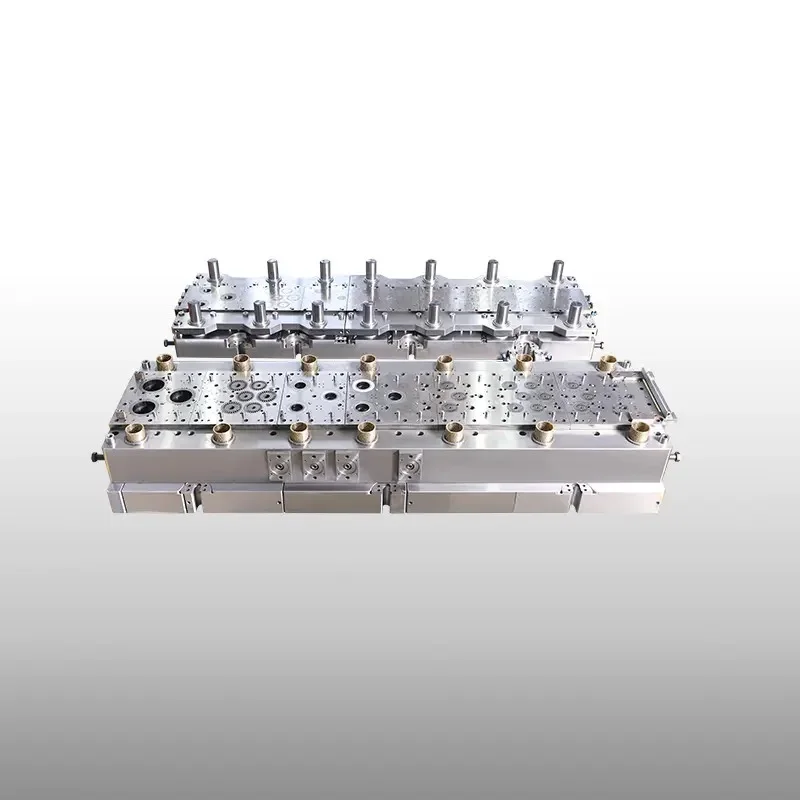

High speed stamping mold is a sophisticated manufacturing technology that allows for the rapid and precise production of metal components. It involves the use of powerful presses and intricately designed molds to shape metal blanks into the desired forms. The process is characterized by its high production rate and exceptional accuracy, making it ideal for mass production of electronic components.

In the production of motor laminations, high speed stamping mold plays a pivotal role. Motor laminations are thin sheets of metal that are stacked together to form the core of an electric motor. The precision of the stamping process ensures that each lamination is identical in size and shape, which is critical for the efficient functioning of the motor. High speed stamping mold allows manufacturers to produce thousands of laminations per hour, significantly reducing production time and costs. Moreover, the high precision of the molds ensures that the laminations fit together perfectly, minimizing energy losses and maximizing the motor’s efficiency.

Similarly, in the manufacturing of electric motor stampings, high speed stamping mold is indispensable. These stampings are used to create various parts of the motor, such as the rotor and stator. The complex shapes and tight tolerances required for these components can be achieved through the use of high speed stamping molds. The molds are designed with great precision to ensure that each stamping is produced to exact specifications. This not only improves the performance of the motor but also enhances its reliability and durability. High speed stamping mold technology enables manufacturers to produce high-quality motor stampings at a fraction of the time and cost compared to traditional manufacturing methods.

| Comprehensive life: | ≥160 million punches |

| Blade die life: | ≥5 million strokes/0.1mm |

| Mold structure: | Three-plate mold base + ball guide |

| Effective cutting edge height: | ≥8mm |

| Blade material: | DJ40 |

| Grooved die form: | Punch grooved die, slow wire finishing, the punch is polished using a special process to remove the oxidation layer |

| Guide parts: | Precision + high hardness |

| Blanking speed during running-in period: | 80-280 punches/minute |

| Blanking speed: | 280-300 punches/minute |

| Concentricity: | ≦0.05mm |

| Protection device: | Equipped with misfeed protection device |

| Punching burr: | ≦0.05mm |

| Riveting force: | 30N |

| Safety device: | Misfeed detection + equal height limit column |

| Product output form: | Conveyor belt Rotor control device Chute control device |

| Plate control device: | Cylinder |

| Mold base material: | Upper and lower mold seats P20. middle unloading seat P20. the second and fourth levels are made on the same set of molds and are interchangeable during production. The shaft hole can be used for three interchangeable pumping plates. |

| Spare parts provided: | 30% of wearing parts |

| Internal plate material: | Cr12MOV |