One of the most notable advantages of using an SLA prototype is the speed at which product designs can move from concept to physical reality. Traditional manufacturing methods often take weeks or even months to produce a workable prototype, but with SLA technology, companies can drastically reduce this timeline. By leveraging rapid curing of liquid resin into solid structures, SLA prototyping allows product teams to create intricate and functional models in just a matter of hours or days. This quick turnaround not only helps businesses stay competitive but also enables faster iterations during the product development cycle.

The efficiency of an SLA prototype also extends beyond speed. Because the process is highly precise, it eliminates many of the common errors associated with manual modeling and traditional prototyping. This means that designers and engineers can focus on improving features and functionality rather than troubleshooting basic flaws. As a result, businesses are better positioned to streamline their product development workflows and launch innovative solutions to the market faster.

High Precision and Accuracy in Design

Another key benefit of using an SLA prototype is the exceptional accuracy it provides. SLA technology is renowned for its ability to reproduce highly detailed models with resolutions as fine as 25 microns. This level of precision ensures that even the most complex geometries and delicate features are accurately represented in the final prototype. For industries such as healthcare, aerospace, and automotive, where accuracy is critical, this capability can make a significant difference in the success of a product.

High precision also allows businesses to conduct thorough testing and validation of their designs. An SLA prototype provides a realistic representation of the final product, enabling engineers to detect potential issues early in the process. This minimizes costly errors during mass production and ensures that the product meets stringent quality standards. By achieving such high levels of accuracy, businesses gain confidence in their designs and significantly reduce the risk of failure in later development stages.

Cost-Effectiveness in the Prototyping Process

While some may perceive advanced technologies as expensive, an SLA prototype can actually help businesses save money throughout the product development process. Traditional prototyping methods often require costly molds, tooling, and materials, which can add up quickly, especially when multiple iterations are needed. SLA prototyping eliminates these expenses by producing models directly from digital files without the need for extensive setup. This makes it a cost-efficient solution for both startups and established companies.

Additionally, SLA prototypes allow companies to identify design flaws early, which prevents expensive rework during production. Because prototypes can be created quickly and at a lower cost, businesses can afford to test multiple versions of their designs before committing to full-scale manufacturing. This iterative approach ensures that the final product is both functional and cost-effective, reducing overall development costs and maximizing return on investment.

Versatility and Material Options

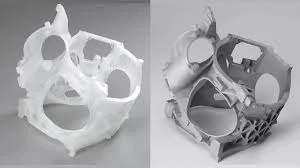

An SLA prototype offers remarkable versatility, making it suitable for a wide range of industries and applications. From functional parts to concept models, SLA technology supports various use cases by offering a broad selection of materials. Depending on the project requirements, designers can choose resins with properties such as flexibility, toughness, heat resistance, or biocompatibility. This flexibility allows SLA prototypes to mimic the mechanical and physical characteristics of final production parts, providing valuable insights during testing.

The ability to choose from multiple materials also enhances creativity and innovation in product development. For instance, a medical device manufacturer can create SLA prototypes with biocompatible resins for patient-specific tools, while an automotive company may select heat-resistant resins for testing engine components. This adaptability ensures that SLA technology remains relevant across industries and provides businesses with the tools they need to develop products tailored to their unique requirements.

Improved Communication and Collaboration

An often-overlooked benefit of using an SLA prototype is its ability to improve communication and collaboration among stakeholders. Digital models and 2D drawings can sometimes fail to convey the full scope of a design, leaving room for misinterpretation. However, a tangible SLA prototype provides a clear and accurate representation of the product, enabling team members, investors, and clients to better understand its form and function. This fosters alignment across departments and minimizes the risk of misunderstandings.

Furthermore, SLA prototypes act as a valuable tool during presentations and product demonstrations. Instead of relying solely on digital visuals, businesses can showcase a physical model that stakeholders can interact with directly. This not only builds trust but also facilitates more productive feedback sessions. With better communication and collaboration, companies can refine their designs more effectively and ensure that the final product aligns with both technical requirements and customer expectations.