When considering composite material production, manufacturers often explore different molding methods to achieve optimal results. The SMC Mould process offers distinct advantages for creating large, durable components, but what factors make it suitable for specific applications?

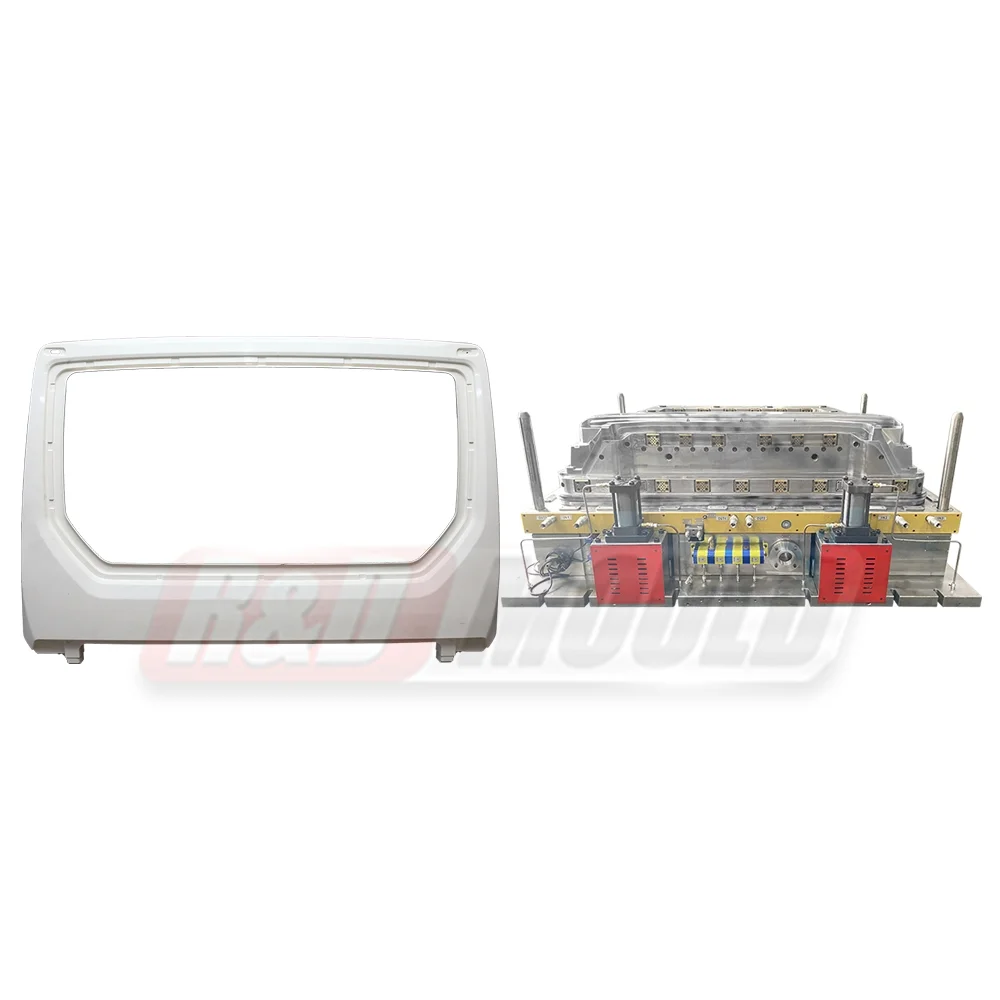

The compression molding technique used in SMC Mould operations begins with placing sheet molding compound into a heated mold cavity. Under controlled temperature and pressure, the material flows to fill the mold, producing components with consistent material distribution. This method proves particularly effective for manufacturing large panel-type products where dimensional stability matters.

Material efficiency represents a notable advantage of the SMC Mould process. Without traditional runner systems or gates, material waste is reduced significantly compared to injection molding. The multi-directional material flow within the mold cavity helps distribute pressure evenly, resulting in lower internal stresses and reduced warping in finished products.

The SMC Mould approach demonstrates special suitability for thin-walled components that require minimal deformation. This capability makes it valuable for producing items like electrical enclosures, automotive body panels, and construction elements where maintaining flatness and precise dimensions contributes to product performance.

Various industries have adopted SMC Mould technology for different applications. The automotive sector utilizes it for manufacturing bumpers, seating components, and grille panels. In infrastructure projects, the process creates durable products like utility covers and drainage components. The building industry employs SMC Mould for structural elements and complete housing systems where the strength-to-weight ratio matters.

When planning to implement SMC Mould production, manufacturers consider factors like mold temperature control, pressure application, and curing parameters. These variables influence both production efficiency and final product quality. Proper mold design accounts for material flow patterns and cooling requirements to achieve consistent results across production runs.

The versatility of SMC Mould technology continues to support innovation across multiple sectors. As material formulations advance and mold design capabilities grow, this manufacturing method adapts to new applications where strength, weight reduction, and production efficiency remain priorities.