As the global demand for clean, reliable, and affordable energy continues to surge, lithium iron phosphate (LFP) batteries are emerging as one of the most transformative innovations in modern energy storage technology. These batteries combine safety, sustainability, and cost-effectiveness—three key factors driving the global transition toward electric mobility, renewable energy adoption, and decentralized power systems.

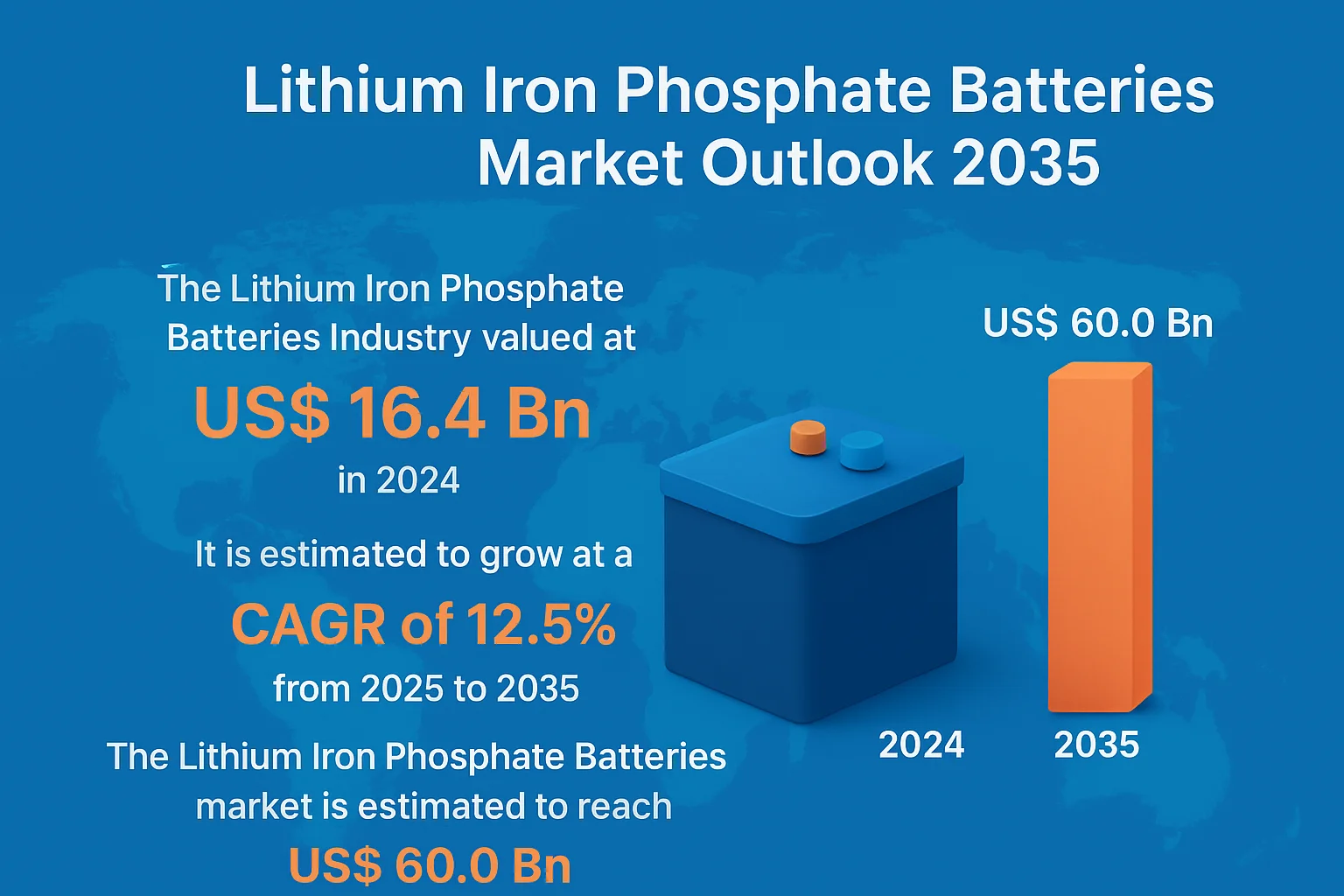

Valued at US$ 16.4 billion in 2024, the global LFP batteries market is projected to grow at an impressive CAGR of 12.5% between 2025 and 2035, reaching nearly US$ 60.0 billion by 2035. This exponential rise reflects how LFP batteries are becoming indispensable in electric vehicles (EVs), grid energy storage, industrial automation, and residential power solutions.

Understanding Lithium Iron Phosphate Batteries

Lithium iron phosphate batteries are a subtype of lithium-ion batteries that use lithium iron phosphate (LiFePO₄) as the cathode material. Unlike traditional lithium-ion chemistries that rely on nickel, manganese, or cobalt (NMC), LFP batteries utilize materials that are abundant, non-toxic, and thermally stable.

This chemistry gives LFP batteries several advantages:

- Superior safety: They are less prone to overheating or thermal runaway.

- Longer life cycle: They can endure over 4,000 charging cycles without major degradation.

- Cost efficiency: They eliminate the use of expensive materials such as cobalt and nickel.

- Eco-friendliness: LFP batteries are easier to recycle and contain fewer hazardous materials.

These benefits make them the ideal choice for applications that require both reliability and affordability—from EVs and renewable energy systems to backup power in industrial and residential setups.

Driving Forces Behind LFP Battery Adoption

1. Electrification of Transportation

The global shift toward electric vehicles is one of the most powerful drivers of the LFP battery market. As governments impose stricter emissions targets and offer incentives for EV adoption, automakers are increasingly turning to LFP technology to balance performance with affordability.

LFP batteries have become particularly popular in entry-level EVs, electric buses, and commercial fleets, where long lifespan, high safety, and cost efficiency matter more than maximum energy density. Leading manufacturers such as Tesla, BYD, and Volkswagen have integrated LFP batteries into their models to reduce production costs and improve safety.

For instance, Tesla’s Model 3 and Model Y Standard Range variants use LFP packs for their strong safety profile and long cycle life, while BYD’s Blade Battery—an LFP-based design—has set new benchmarks in safety testing and performance.

As EV demand continues to soar in Asia-Pacific, Europe, and North America, the scalability and cost competitiveness of LFP batteries will make them an essential part of the global electric mobility ecosystem.

👉 Full Market Report available for delivery. For purchase or customization, please request here

2. Energy Storage for a Renewable Future

The world’s transition toward renewable energy sources like solar and wind depends heavily on reliable energy storage systems (ESS) that can balance supply and demand. LFP batteries are ideally suited for grid-scale and residential storage due to their deep discharge capabilities, long life, and superior safety performance.

Companies such as Tesla (with its Megapack and Powerwall) and BYD are leading the charge by deploying LFP-based storage systems that stabilize power grids and provide backup during outages. For example, Tesla’s Megapacks are now a key component of several large-scale renewable energy projects in the U.S., Australia, and Europe.

In addition, governments around the world are incentivizing renewable integration through subsidies and infrastructure investments. Programs like the U.S. Inflation Reduction Act (IRA) and China’s carbon neutrality goals are promoting LFP battery deployment in both commercial and residential storage.

By enabling round-the-clock renewable energy use, LFP batteries are helping nations build a cleaner, more resilient energy future.

3. Affordability and Material Sustainability

Unlike conventional lithium-ion batteries that rely on supply-constrained materials like cobalt and nickel, LFP batteries are made from iron and phosphate, which are abundant and inexpensive. This availability reduces both production costs and supply chain vulnerabilities.

As a result, LFP batteries are far more cost-effective and scalable, making them ideal for mass-market EVs, developing economies, and rural electrification projects. This affordability also supports sustainability, as LFP batteries avoid the environmental and ethical challenges often associated with cobalt mining.

Moreover, as advancements in cell design, energy density, and manufacturing efficiency continue, the cost gap between LFP and higher-density chemistries is narrowing—making LFP batteries even more attractive for mainstream adoption.

Regional and Industry Insights

The Asia-Pacific region, particularly China, dominates global LFP battery production and consumption, accounting for roughly 35% of total market share. Major companies such as CATL, BYD, and Gotion High-Tech are leading innovation in LFP technology and large-scale manufacturing.

North America and Europe are also witnessing a surge in investments as automakers and energy companies localize production to reduce import dependence. Projects like CATL’s partnership with Stellantis in Spain and Tesla’s U.S.-based LFP manufacturing initiatives signal a new wave of global capacity expansion.

Industries such as automotive, energy storage, consumer electronics, and industrial automation are among the largest adopters of LFP batteries. With growing focus on sustainability and cost optimization, the trend is set to strengthen further.

The Road Ahead: Clean, Safe, and Scalable Energy

As the world accelerates toward a low-carbon economy, lithium iron phosphate batteries are proving to be a cornerstone of the clean energy revolution. Their unmatched combination of safety, longevity, and affordability makes them ideal for the next generation of EVs and renewable energy systems.

With continuous advancements in energy density, fast charging, and manufacturing efficiency, LFP batteries are expected to become even more competitive and versatile in the coming decade.

In essence, the rise of lithium iron phosphate batteries marks not just a technological breakthrough but a global movement toward cleaner, safer, and more inclusive energy access. From powering tomorrow’s electric vehicles to storing the sun’s energy for future use, LFP batteries are truly powering the future of clean and affordable energy.

Contact Us

Transparency Market Research Inc.

CORPORATE HEADQUARTER DOWNTOWN,

1000 N. West Street,

Suite 1200, Wilmington, Delaware 19801 USA

Tel: +1-518-618-1030

USA - Canada Toll Free: 866-552-3453