Komatsu excavators are renowned for their power, durability, and sophisticated engineering, making them staples in demanding construction and mining operations. A critical component responsible for delivering power to the tracks is the final drive (also known as the travel motor or planetary gearbox). This complex assembly multiplies torque from the hydraulic motor and transmits it to the sprocket. Over time, due to immense stress and wear, final drives can develop increased play, or backlash. This looseness is not merely a minor issue; it's a critical symptom indicating significant internal wear that, if ignored, can lead to catastrophic failure, costly downtime, and potential damage to other undercarriage components. This article provides an expert guide to diagnosing increased play in Komatsu excavator final drives, outlining effective repair strategies and emphasizing the crucial importance of proper gear selection.

Understanding Increased Play (Backlash) and Its Causes

Play, or backlash, refers to the free movement or "slop" between meshing gear teeth within the final drive's planetary gear system. While a minuscule amount of backlash is necessary for lubrication and thermal expansion, excessive play indicates that significant wear has occurred. The primary causes include:

-

Gear Tooth Wear: This is the most common cause. Continuous high torque, abrasive contamination in the gear oil, or improper lubrication leads to the wearing down of the surfaces of the sun gear, planet gears, and ring gear teeth. As the teeth thin, the gap between them increases.

-

Bearing Wear/Failure: Final drives rely on heavy-duty bearings to support the shafts and planetary carriers. Worn or failed bearings allow these components to shift slightly, altering gear alignment and increasing backlash. Bearing failure often accelerates gear wear dramatically.

-

Contamination: Abrasive particles (metal shavings from internal wear, dirt ingress through faulty seals) suspended in the gear oil act like a grinding compound, rapidly eroding gear teeth and damaging bearings.

-

Lubrication Failure: Using the wrong type of gear oil, operating with low oil levels, or failing to change the oil according to the Komatsu maintenance schedule compromises lubrication, leading to increased friction, overheating, and accelerated wear of gears and bearings.

-

Shock Loads and Overloading: Abrupt direction changes, impacts, or consistently operating the excavator beyond its load limits place extreme stress on the final drive gears, potentially causing chipping or fatigue failure.

Symptoms and Diagnostics of Final Drive Play

Identifying excessive play early is crucial for preventing complete final drive failure.

Operational Symptoms:

-

Clunking or Jerking: A noticeable clunk or jerk when changing travel direction, starting, or stopping is a classic sign of excessive backlash between the gears.

-

Reduced Travel Power or Speed: Significant internal wear reduces the efficiency of torque transfer, making the excavator feel sluggish or weak during travel.

-

Machine Pulling to One Side: If one final drive has significantly more play or wear than the other, the machine may tend to veer to one side during straight travel.

-

Excessive Noise: Grinding, whining, or rumbling sounds emanating from the final drive area, especially under load, often indicate severe gear or bearing wear.

Diagnostic Methods:

-

Manual Check (Rocking): With the machine safely parked and secured, attempt to manually rock the drive sprocket back and forth (rotationally). Any significant free movement before the track begins to engage indicates internal play. Compare the play between the left and right final drives.

-

Oil Analysis: This is a vital diagnostic tool. Regularly analyzing the final drive gear oil for metal content (especially iron and steel from gears, and potentially copper/bronze from bearing cages) provides early warning of accelerated wear long before symptoms become obvious. High particle counts also indicate contamination issues.

-

Temperature Monitoring: Use an infrared thermometer to check the operating temperature of the final drive casing after use. Excessive heat compared to the other side or to normal operating temperatures suggests high internal friction due to wear or lubrication problems.

-

Visual Inspection: Check the final drive casing for any signs of external leaks, particularly around the main seal and mounting bolts. Leaks indicate potential seal failure and a risk of oil loss and contamination ingress.

-

Internal Inspection (During Repair): The most definitive diagnosis comes from disassembling the final drive. This allows for direct visual inspection and measurement of gear teeth, bearings, shafts, and seals to assess the extent and cause of the wear.

Repair Strategies and Critical Gear Selection

Once excessive play is confirmed, repair is necessary to prevent total failure. A final drive repair is a complex task requiring precision and the correct parts.

-

Disassembly and Defect Analysis: The final drive must be carefully disassembled, and all components meticulously cleaned and inspected. Measure gear tooth thickness, check bearing clearances, and look for signs of scoring, pitting, heat discoloration, or cracking.

-

The Critical Role of Gear Selection: Replacing worn gears is often the core of the repair.

-

Matching Sets: It is highly recommended to replace planetary gear sets (sun gear and associated planet gears) together, even if only one component shows severe wear. Mixing worn and new gears leads to improper meshing, uneven load distribution, and rapid failure of the new parts.

-

Material and Hardness: Gears in Komatsu final drives are made from specialized, hardened steel alloys. Using high-quality replacement gears manufactured to precise OEM specifications for hardness, tooth profile, and surface finish is non-negotiable. Low-quality gears made from softer materials or with incorrect heat treatment will fail quickly under load.

-

Ring Gear Inspection: Inspect the internal ring gear carefully. If it shows significant wear or damage, it must also be replaced, often requiring replacement of the entire final drive housing.

-

-

Bearing and Seal Replacement: Always replace all bearings and seals during a final drive rebuild, regardless of their apparent condition. These components are subjected to immense stress and are relatively inexpensive compared to the cost of a repeat failure. Use only high-quality bearings and seals.

-

Reassembly and Lubrication: Reassemble the final drive following Komatsu's precise procedures and torque specifications. Fill with the correct type and quantity of high-quality gear oil specified for that model.

Prevention and the Importance of Quality Parts

Preventing excessive final drive play revolves around diligent maintenance and operational care.

-

Regular Oil Changes: Strictly adhere to Komatsu’s recommended intervals for changing the final drive gear oil. Clean oil is the lifeblood of the system.

-

Contamination Control: Protect the final drive breathers and regularly inspect seals for leaks to prevent dirt and water ingress.

-

Operator Awareness: Train operators to avoid unnecessarily abrupt direction changes under heavy load and report any unusual noises or performance changes immediately.

-

Genuine/Quality Parts: The longevity and reliability of a repaired final drive depend entirely on the quality of the replacement parts. Using genuine Komatsu parts or high-quality certified analogues for gears and bearings is the only way to ensure the repair lasts.

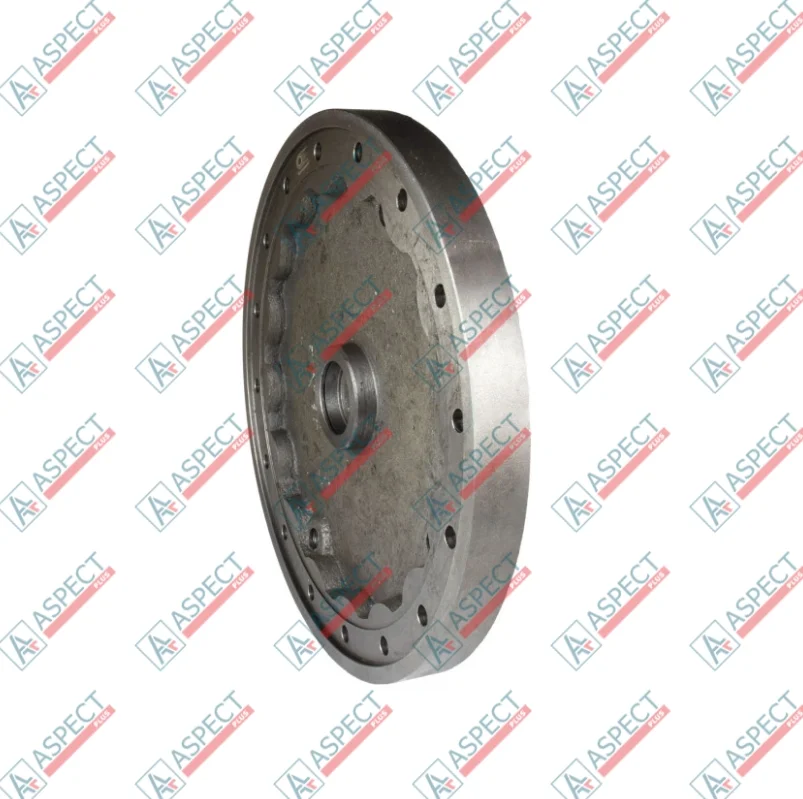

Our company Aspect Plus offers a wide selection of high-quality spare parts for Komatsu final drives, including gear sets, bearings, and seals, manufactured to meet demanding specifications.

Conclusion

Increased play in a Komatsu excavator final drive is a serious warning sign of internal wear that demands immediate attention. Systematic diagnostics, including manual checks and regular oil analysis, are crucial for early detection. Effective, long-lasting repair hinges on a meticulous rebuild process and, most importantly, the strategic selection of high-quality replacement gears and bearings. By prioritizing preventive maintenance and investing in quality spare parts, owners can significantly extend the lifespan of their final drives, ensuring the continued reliability and productivity of their valuable Komatsu equipment.

For expert diagnostics, high-quality final drive components, and professional advice on Komatsu excavator maintenance, contact the specialists at Aspect Plus.