As the core raw material of the third-generation oral chemical factories, cephalosporins, cefixime, have become an important basic raw material for the treatment of community-acquired infections in the pharmaceutical chemical factories because of their strong antibacterial activity against gram-negative bacteria and good oral absorption characteristics. Its technical maturity and industrial supply stability directly affect the clinical accessibility and therapeutic effect of anti-infective drugs. This broad-spectrum antibacterial raw material drug was limited by the complexity of the synthesis process in the early stage, and there were some problems, such as high production cost and difficult impurity control. With the iteration of organic synthesis technology and separation and purification processes, large-scale and high-quality production was gradually realized, which provided stable raw material support for the development of oral anti-infection preparations and was the key link between chemical pharmaceutical technology and clinical anti-infection needs.

In the pharmaceutical field, the core application of cefixime bulk drug focuses on the production of oral anti-infective preparations, and its mechanism of action is to play a bactericidal role by inhibiting the synthesis of bacterial cell walls, which is suitable for the treatment of common infectious diseases such as respiratory tract infection, urinary tract infection, and biliary tract infection. As a representative raw material of oral chemical factories, cephalosporins, the quality of cefixime directly determines the antibacterial activity and safety of downstream preparations. Its good tissue penetration and long half-life can ensure the effective therapeutic concentration of drugs at infected sites, reduce the frequency of taking drugs, improve the compliance of patients, and provide the core direction for pharmaceutical companies in the field of oral anti-infective drugs, and promote the optimization of clinical anti-infective treatment programs.

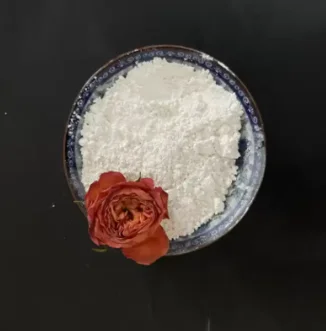

Optimizing the production process is the core driving force to promote the development of the chemical factories' cefixime API industry. The synthesis of cefixime bulk drug involves multi-step organic reactions, and there are some problems in the early process, such as complicated reaction steps, low purity of intermediates, and a large amount of organic solvents. Nowadays, by optimizing the reaction route and adopting new catalysts, the activation energy of the reaction is reduced and the synthesis period is shortened. At the same time, continuous flow reaction technology and high-efficiency separation and purification processes, such as high-performance liquid chromatography purification and crystallization process optimization, are introduced to greatly improve product purity and reduce impurity content, and ensure that the chemical purity and optical purity of cefixime raw materials meet the medical standards. These process upgrades not only reduce the production cost and environmental pressure, but also ensure the quality consistency between product batches and meet the strict requirements of the pharmaceutical industry for the stability of APIs.

The improvement of the quality control system provides a guarantee for the safety of the clinical application of cefixime. The global pharmaceutical chemical factories have formulated clear specifications for the purity, related substance limits, moisture content, and heavy metal residues of cefixime, and enterprises need to establish a quality traceability system for the whole process from raw material procurement, synthetic reaction, to finished product inspection. By monitoring the key parameters in the reaction process in real time, the finished product is verified by ultra-high performance liquid chromatography and other precision detection technologiestoto accurately control the impurity content, avoid adverse reactions caused by related substances exceeding the standard, ensure that cefixime raw materials meet the drug regulatory requirements of different countries and regions, and lay the foundation for the global circulation of products.

In the future, with the refinement of anti-infection treatment demand and the innovation of chemical pharmaceutical technology, the research and development of cefixime bulk drug will further focus on improving drug resistance, optimizing dosage form adaptability, and developing green production technology. At the same time, the chemical factories will continue to reduce the consumption of organic solvents through process innovation, promote the low-carbon and environmental protection of the production process, and enhance the sustainable development capability of the industry. Cefexoxime API will continue to inject vitality into the anti-infection field of the pharmaceutical industry through the deep integration of technical upgrading and industrial application, provide safer and more efficient raw material support for oral anti-infection drugs in clinics, and help improve the global anti-infection treatment system.

Chemical factories Cefexoxime API: How can technology help fight infection?