Carbon fiber has revolutionized various industries, from aerospace to automotive and sporting goods. One type of carbon fiber fabric that has gained significant popularity is bidirectional carbon fiber fabric. Its unique properties and versatile applications make it a sought-after material. In this blog, we will delve into the world of bidirectional carbon fiber fabric, exploring its characteristics, manufacturing process, and diverse uses.

I. Understanding Bidirectional Carbon Fiber Fabric

1.What is Bidirectional Carbon Fiber Fabric?

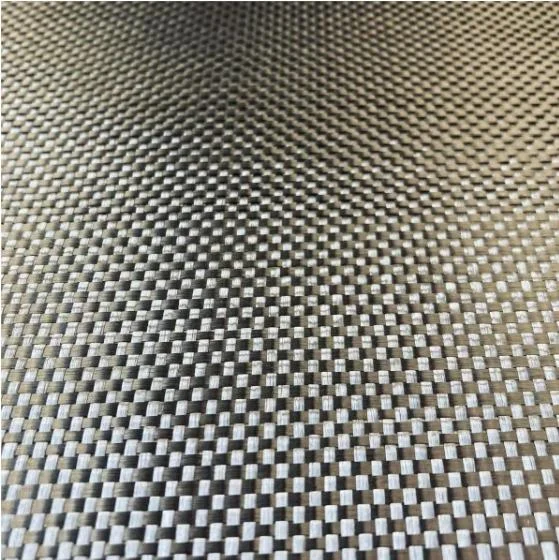

Define bidirectional carbon fiber fabric as a type of woven fabric that consists of carbon fiber strands running in two primary directions: warp and weft.

2.Benefits and Properties:

Highlight the key advantages of bidirectional carbon fiber fabric, such as high strength-to-weight ratio, excellent stiffness, and resistance to corrosion and fatigue.

Discuss its low thermal expansion, electromagnetic transparency, and superior chemical resistance.

II. Manufacturing Process

1.Carbon Fiber Production:

Briefly explain the process of carbon fiber production, which involves precursor material conversion, fiber spinning, and carbonization.

2.Weaving Process:

Describe the weaving process used to create bidirectional carbon fiber fabric, including the arrangement of warp and weft yarns to achieve the desired bidirectional properties.

III. Applications of Bidirectional Carbon Fiber Fabric

1.Aerospace Industry:

Discuss how bidirectional carbon fiber fabric finds extensive use in aerospace applications, including aircraft components, spacecraft structures, and satellite components.

2.Automotive Industry:

Explore the usage of bidirectional carbon fiber fabric in the automotive sector, particularly in lightweight vehicle parts, such as body panels, interior components, and chassis reinforcements.

3.Sports and Recreation:

Highlight how bidirectional carbon fiber fabric is utilized in sports equipment, such as bicycles, tennis rackets, hockey sticks, and fishing rods, to enhance performance and durability.

4.Construction and Infrastructure:

Discuss the applications of bidirectional carbon fiber fabric in the construction industry, including strengthening and reinforcing concrete structures, bridges, and pipelines.

5.Marine Industry:

Explain how bidirectional carbon fiber fabric is used in the marine sector for manufacturing boat hulls, masts, and other components due to its high strength and corrosion resistance.

IV. Tips for Working with Bidirectional Carbon Fiber Fabric

1.Cutting and Shaping:

Provide guidelines for cutting and shaping bidirectional carbon fiber fabric, emphasizing the importance of using appropriate tools and techniques to prevent fiber damage.

2.Resin Selection:

Explain the significance of selecting the right resin for impregnation and curing processes when working with bidirectional carbon fiber fabric, ensuring optimal bonding and strength.

3.Molding and Lamination:

Offer tips for molding and laminating bidirectional carbon fiber fabric, including the use of vacuum bagging or autoclave processes to achieve proper consolidation and void-free results.

V. Future Trends and Innovations

1.Advancements in Manufacturing Techniques:

Discuss emerging manufacturing techniques, such as automated weaving and 3D printing, that promise to enhance the quality, efficiency, and customization of bidirectional carbon fiber fabric.

2.Integration with Other Materials:

Explore the potential for integrating bidirectional carbon fiber fabric with other materials, like polymers or metals, to create hybrid composites with enhanced properties.

Conclusion

Bidirectional carbon fiber fabric is a remarkable material with a wide range of applications across industries. Its exceptional strength, lightweight nature, and resistance to various environmental factors make it a preferred choice for numerous high-performance products. By understanding its properties, manufacturing process, and best practices for working with it, manufacturers and engineers can harness the full potential of bidirectional carbon fiber fabric and continue to push the boundaries of innovation in their respective fields.