In manufacturing and engineering, reliability is more than a technical metric—it’s a key factor in how long a product lasts and how often it fails. When teams need a structured way to predict product reliability, they often turn to industry standards like Telcordia SR332. This standard provides guidelines for calculating Mean Time Between Failures (MTBF), a critical measure of how reliable a product or system is expected to be.

If you’re new to MTBF SR332 or want to understand how it affects product design, maintenance, and quality assurance, this guide breaks down the essentials in simple, practical terms.

1. What MTBF SR332 Means

MTBF stands for Mean Time Between Failures. It represents the average time a system or component operates before experiencing a failure. The SR332 standard, developed by Telcordia Technologies, gives manufacturers a detailed framework to calculate this metric accurately.

Unlike generic reliability formulas, SR332 provides defined models, stress factors, and failure rate data that apply to real-world electronic and mechanical components. It’s often used in industries like telecommunications, electronics, defense, and aerospace, where high reliability is critical.

In short, SR332 helps manufacturers predict performance and make informed decisions about product design, maintenance schedules, and expected lifespan.

2. The Purpose of SR332 in Reliability Engineering

The SR332 standard was created to offer consistency. Before it existed, companies used different reliability models that produced inconsistent results. SR332 changed that by establishing a universal approach to MTBF predictions.

It helps engineers and product designers evaluate how environmental conditions, temperature, and operational stress impact a component’s life. Using these guidelines, companies can compare products fairly, forecast maintenance needs, and set realistic expectations for product warranties.

In industries that depend on uptime—like data centers or telecom—these calculations are essential for risk management and planning.

3. How SR332 Calculates Failure Rates

The SR332 model calculates failure rates using three main prediction methods, each depending on how much data is available:

-

Method I: Parts Count Prediction

Used early in design, when limited data is available. It gives a basic estimate based on known component failure rates. -

Method II: Parts Stress Analysis

A more detailed approach that considers environmental and operational stresses. It’s used once the design and material choices are known. -

Method III: Field Failure Data Analysis

This method uses actual field performance data to refine earlier predictions. It’s considered the most accurate since it reflects real-world performance.

Each method builds on the previous one, allowing teams to improve prediction accuracy as more data becomes available during product development.

4. Why Manufacturers Rely on SR332

Manufacturers value SR332 because it brings structure and transparency to reliability prediction. The standard helps design teams identify weak points before production begins, reducing the risk of costly redesigns or recalls.

It also provides a shared language between reliability engineers, quality teams, and customers. When you report MTBF values using SR332, clients know exactly how those numbers were calculated and can trust that the results meet industry expectations.

In regulated sectors like telecommunications or medical devices, compliance with SR332 often becomes part of the qualification process, making it both a technical and business requirement.

5. Common Misunderstandings About MTBF

Despite its usefulness, MTBF is often misunderstood. It’s important to remember that MTBF is a statistical prediction, not a guarantee. For example, an MTBF of 100,000 hours doesn’t mean every unit will last that long—it means that, on average, one failure is expected per 100,000 hours of total operation time across many units.

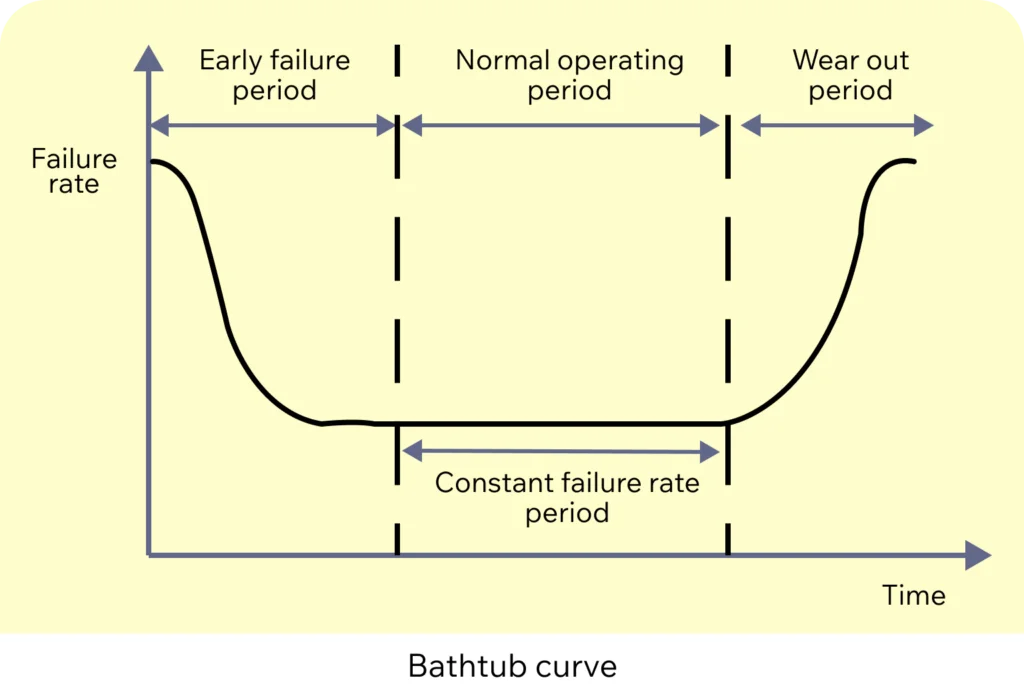

MTBF also doesn’t account for product wear-out or external damage. It assumes random failures over time, which is useful for planning but not a replacement for real-world testing and field feedback.

Reliability consultants often combine SR332-based predictions with environmental testing, stress analysis, and maintenance data to create a more complete reliability picture.

6. Using SR332 in Design and Decision Making

When applied correctly, SR332 helps teams make design decisions that balance performance, cost, and reliability. During early development, it guides component selection and helps estimate life expectancy. Later, it supports testing strategies and maintenance planning.

For example, a company designing telecom equipment might use SR332 data to determine which components are most likely to fail under high heat or humidity. That insight can influence material choices or ventilation design. Over time, integrating these calculations into the product lifecycle leads to fewer failures, lower service costs, and improved customer satisfaction.

The standard also evolves with technology. As new components and materials emerge, updated versions of SR332 provide the latest failure rate data to keep reliability models accurate.

Final Thoughts

MTBF SR332 is one of the most trusted tools in reliability engineering. It gives companies a structured, data-driven way to estimate how long their products will perform before failure. By following this standard, manufacturers can improve product reliability, reduce maintenance costs, and build stronger customer confidence.

Whether you’re designing a new system or analyzing an existing one, understanding and applying SR332 can make your reliability predictions more accurate and actionable.