The nitronic alloy 50 round bar is a high-strength and corrosion-resistant stainless steel product used in many industries such as marine, chemical, and food processing. It offers excellent mechanical properties and toughness even at low temperatures. To maintain its performance, manufacturers follow strict standards and testing methods during production.

Understanding Nitronic Alloy 50 Round Bar

An alloy nitronic 50 round bar is made from a nitrogen-strengthened austenitic stainless steel. It combines high strength with excellent corrosion resistance, making it suitable for harsh conditions. Compared to other stainless steels, it provides better resistance to pitting, crevice corrosion, and stress corrosion cracking.

Common uses include pumps, shafts, valves, fasteners, and marine equipment where both strength and corrosion resistance are required.

Manufacturing Standards

Every Nitronic 50 Round Bars Manufacturer follows specific manufacturing standards to ensure the bars meet international quality requirements. These standards define the material composition, mechanical properties, dimensions, and surface finish.

Some key standards include:

-

ASTM A276 / A479 – Covers stainless steel bars and shapes for general and pressure vessel applications.

-

ASME SA276 / SA479 – Used in high-temperature and pressure systems.

-

AMS 5764 – Specifies requirements for aircraft and aerospace applications.

-

EN 10088-3 – European standard for stainless steel products used in engineering applications.

Following these standards helps maintain uniformity, performance, and safety in all nitronic alloy 50 round bar products.

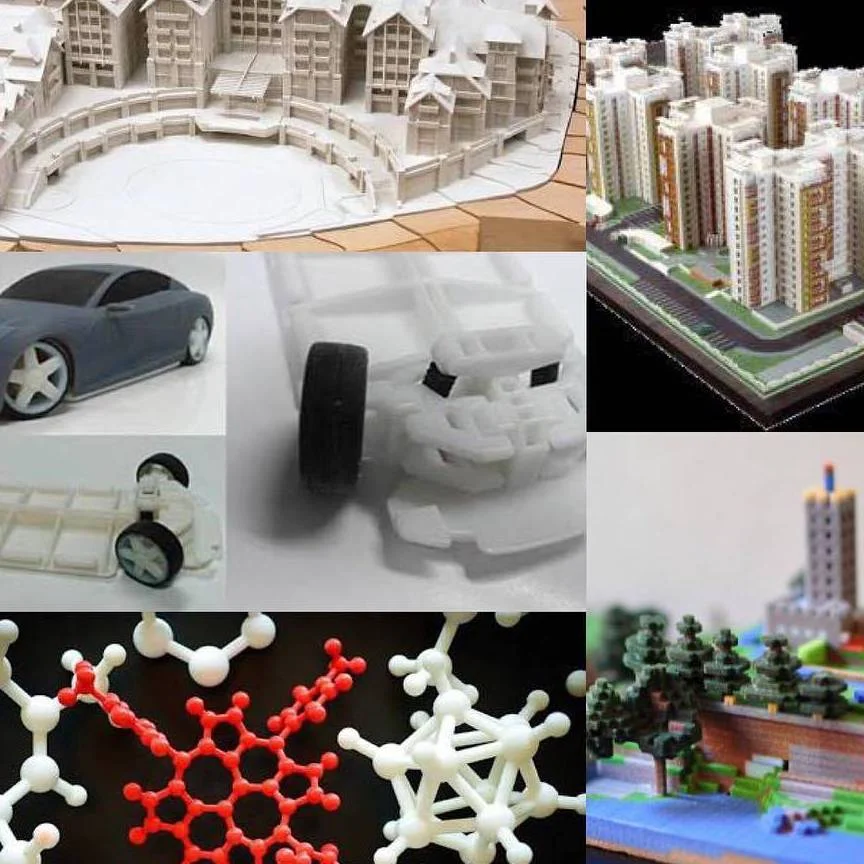

Manufacturing Process

The production of an alloy nitronic 50 round bar involves several controlled steps:

-

Raw Material Selection – High-quality alloying elements like chromium, nickel, and manganese are used to achieve the desired composition.

-

Melting and Refining – The alloy is melted in an electric furnace and refined to remove impurities.

-

Hot Rolling – The molten metal is shaped into bars at high temperatures to achieve the required dimensions.

-

Heat Treatment – Improves mechanical properties and enhances corrosion resistance.

-

Cold Working – Further refines surface finish and tolerance.

-

Final Inspection – Each bar undergoes quality checks before dispatch.

These steps ensure consistency, precision, and durability in every nitronic alloy 50 round bar produced.

Quality Testing Procedures

Testing plays an important role in maintaining the reliability of Nitronic 50 Round Bars Manufacturer products. Various tests are performed to confirm the mechanical strength, chemical composition, and surface quality.

1. Chemical Analysis

Ensures the composition meets the required standards. Elements like chromium, nickel, and manganese are carefully measured.

2. Tensile and Hardness Test

Determines the bar’s strength, ductility, and hardness under different loads.

3. Ultrasonic Testing

Detects any internal cracks or inclusions that might affect performance.

4. Corrosion Resistance Test

Verifies how well the material resists rust and pitting when exposed to moisture or chemicals.

5. Dimensional Inspection

Checks for accurate diameter, length, and straightness according to specified tolerances.

6. Visual and Surface Check

Examines the surface for defects such as scratches, dents, or scales.

Importance of Standards and Testing

Adhering to standards and conducting proper testing ensures that nitronic alloy 50 round bar products meet global expectations for strength, durability, and corrosion resistance. These measures help industries rely on them for demanding applications like offshore structures, chemical processing units, and marine components.

By maintaining high manufacturing and testing quality, every Nitronic 50 Round Bars Manufacturer ensures customer satisfaction and long-lasting performance.

Conclusion

The production of alloy nitronic 50 round bar involves strict control over materials, processes, and testing to guarantee consistent quality. From selecting the right alloy composition to following ASTM and ASME standards, every step ensures that the final product performs reliably in critical environments. Proper manufacturing and testing practices make these bars a trusted choice for industries worldwide.