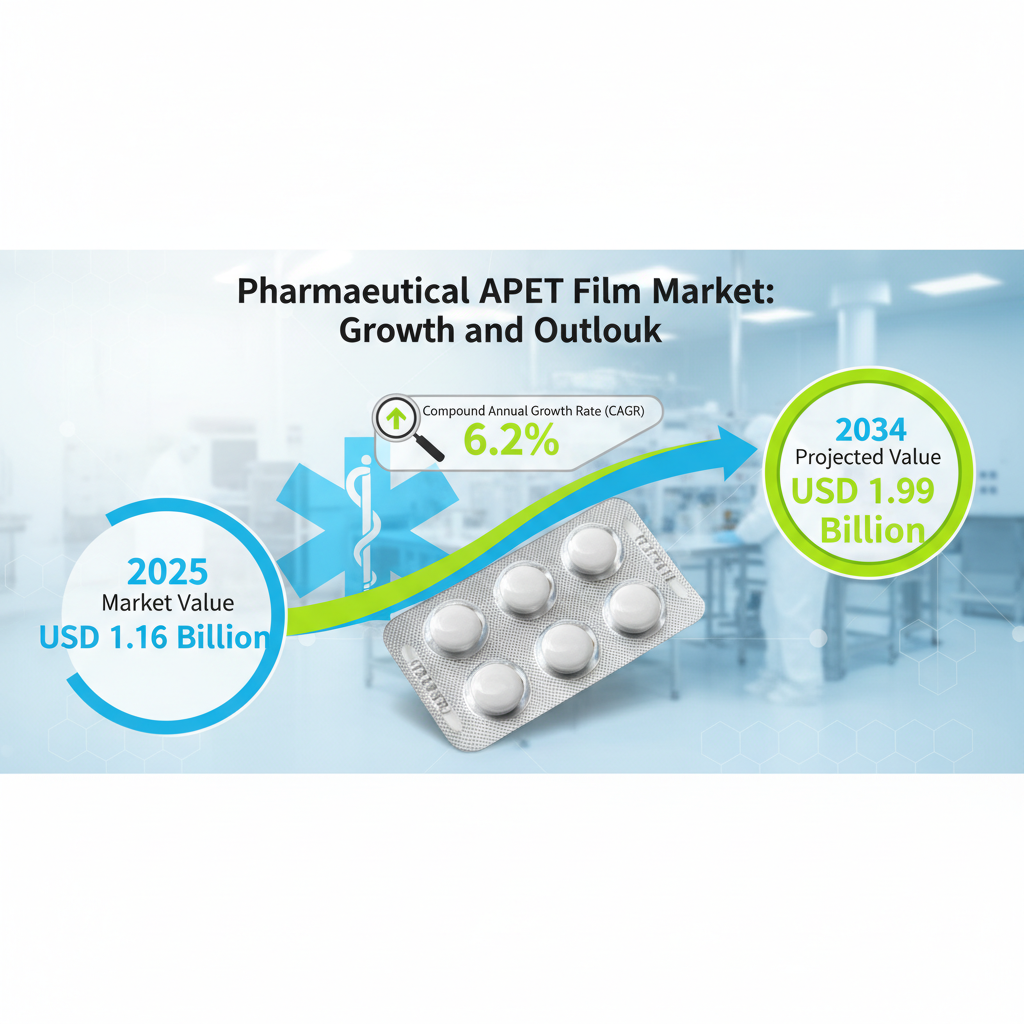

The pharmaceutical APET (Amorphous Polyethylene Terephthalate) film market is undergoing significant growth, projected to reach USD 1.99 billion by 2034, up from USD 1.16 billion in 2025, growing at a compound annual growth rate (CAGR) of 6.2%. This market expansion is largely driven by the increasing demand for safe, efficient, and eco-friendly packaging solutions within the pharmaceutical industry. As telemedicine usage rises, the demand for safe and hygienic packaging for pharmaceuticals and medical devices has surged. The rise of online ordering systems and increased awareness of environmental concerns are fueling the shift toward more sustainable packaging options.

Market Insights:

As the global pharmaceutical packaging industry grows, so does the demand for APET films. This material, valued for its clarity, strength, and environmental sustainability, is in high demand for packaging pharmaceutical products such as tablets, capsules, and injectables. APET films offer several advantages, including:

-

Eco-Friendly Properties: APET films are recyclable and require less energy to produce compared to other plastics like PVC, making them a more environmentally friendly option for pharmaceutical packaging.

-

Hygienic and Safe: The non-toxic, moisture-resistant nature of APET films ensures that pharmaceutical products remain protected from contaminants, keeping them safe for consumer use.

-

Strength and Durability: APET films are strong, providing excellent protection against physical damage and offering a lightweight yet durable solution for packaging pharmaceutical products.

The market for pharmaceutical APET films is also witnessing growing demand from the food and beverage industry, where the need for contamination-free packaging has driven further adoption of these materials.

Invest in Our Premium Strategic Solution: https://www.towardspackaging.com/checkout/5323

Market Segments:

-

By Type:

-

Anti-Fog APET Films: The anti-fog APET film segment led the market in 2024. These films prevent moisture accumulation, ensuring that the packaging remains clear and contamination-free. The anti-fog APET film is widely used in packaging food and pharmaceutical products, offering excellent visibility and protection.

-

Standard APET Films: These films are commonly used for blister packaging, providing strength and clarity to protect sensitive pharmaceutical products from damage.

-

-

By Application:

-

Blister Packaging: The blister packaging segment is the largest application area for pharmaceutical APET films. Blister packs provide excellent protection against moisture, dust, and physical damage, making them ideal for packaging tablets, capsules, and other pharmaceutical products.

-

Thermoforming Films: Thermoformed films are used in packaging various pharmaceutical devices and products, offering flexibility and protection while maintaining the integrity of the contents.

-

-

By End-User:

-

Pharmaceutical Companies: Pharmaceutical companies are the largest consumers of APET films, using them to package a wide range of drugs, including tablets, capsules, and injectables.

-

Medical Device Manufacturers: The medical device sector is also a key consumer of APET films, which are used to package devices such as syringes, needles, and diagnostic tools.

-

Regional Insights:

The pharmaceutical APET film market is experiencing significant growth across various regions, with Asia Pacific leading the way. The rising demand for healthcare products, coupled with an increase in chronic diseases, has made this region a key growth driver for the pharmaceutical APET film market.

Frequently Asked Questions (FAQs):

-

What is the projected growth rate of the pharmaceutical APET film market?

The pharmaceutical APET film market is projected to grow at a CAGR of 6.2%, reaching USD 1.99 billion by 2034 from USD 1.16 billion in 2025. -

What are the key applications of APET films in the pharmaceutical industry?

APET films are primarily used for blister packaging, thermoforming, and medical device packaging due to their strength, clarity, and resistance to contamination. -

What are the environmental benefits of APET films?

APET films are recyclable and require less energy to produce compared to other plastics, making them a more eco-friendly option for pharmaceutical packaging. -

Which regions are leading in the pharmaceutical APET film market?

Asia Pacific is the largest market for pharmaceutical APET films, with North America expected to grow at the fastest rate due to rising demand for sustainable packaging solutions. -

What are the major drivers of the pharmaceutical APET film market?

Key drivers include the rising demand for hygienic packaging, advancements in manufacturing technology, increased investment in the healthcare sector, and the growth of online pharmaceutical sales.

Source : https://www.towardspackaging.com/insights/pharmaceutical-apet-film-market-sizing