In electrical systems, the importance of an insulation monitor device cannot be overstated. This device plays a crucial role in ensuring the safety and efficiency of the system by continuously monitoring the insulation resistance between live conductors and earth. By detecting any insulation faults or deterioration, the insulation monitor device helps prevent potential hazards such as electric shocks, fires, and equipment damage. Therefore, understanding the significance of this device is essential for maintaining a reliable and secure electrical system.

What is an Insulation Monitor Device?

An insulation monitor device (IMD) is an electronic device that continuously monitors the insulation resistance of an electrical system. It measures the leakage current flowing through the insulation and alerts the operator if the insulation resistance falls below a predetermined threshold. The IMD provides real-time information about the condition of the insulation, allowing for timely action to be taken to prevent electrical faults.

Preventing Electrical Accidents

One of the primary reasons for using an insulation monitor device is to prevent electrical accidents. Faulty insulation can lead to leakage currents, which can cause electric shocks to humans or damage to equipment. By continuously monitoring the insulation resistance, an IMD can detect insulation degradation at an early stage, allowing for prompt repairs or replacements to be made before accidents occur.

Protecting Equipment and Infrastructure

Electrical systems are often expensive and critical to the operation of various industries. Faulty insulation can lead to short circuits, equipment damage, and even fires. An insulation monitor device helps protect equipment and infrastructure by providing early warning signs of insulation deterioration. By detecting insulation faults, the IMD allows for preventive maintenance, reducing the risk of equipment failure and costly downtime.

Ensuring System Reliability

Reliable electrical systems are essential for uninterrupted power supply and efficient operation. Insulation degradation can lead to unexpected system failures, resulting in power outages and disruptions. An insulation monitor device continuously monitors the insulation resistance, ensuring the reliability of the electrical system. By detecting insulation faults early on, the IMD allows for proactive maintenance, minimizing the risk of system failures.

Compliance with Safety Standards

Insulation monitor devices are often required by safety standards and regulations. These standards aim to ensure the safety of electrical systems and protect individuals from electrical hazards. By installing an IMD, electrical systems can comply with these standards, demonstrating a commitment to safety and reducing the risk of legal liabilities.

Conclusion

In conclusion, insulation monitor devices play a crucial role in ensuring the safety and reliability of electrical systems. By continuously monitoring the insulation resistance, these devices provide early warning signs of insulation degradation, allowing for timely action to be taken. They help prevent electrical accidents, protect equipment and infrastructure, ensure system reliability, and comply with safety standards. Investing in insulation monitor devices is a proactive approach to maintaining the integrity of electrical systems and safeguarding lives and assets.

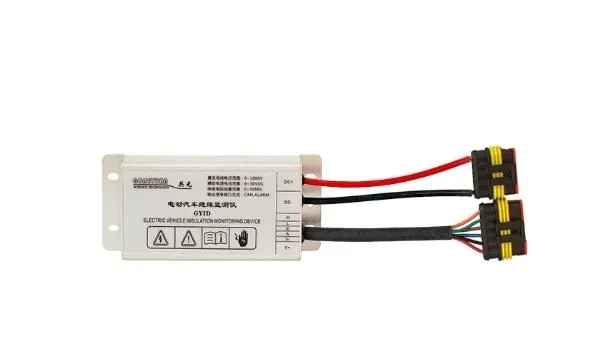

Ensuring Electric Vehicle Safety: The Significance of GYIM Insulation Monitoring Devices