Top-Rated Radius Gauge for Precision Measurement Tasks

Precision is critical in any manufacturing and engineering setting. No matter what you are machining—whether it’s components for a machine, checking out a curved edge, or verifying a profile—using the right measurement tool is highly important to be precise and efficient. The radius gauge is one of the most used tools for inspecting concave and convex surfaces. Its simple makeup, quick reading capability, and trustworthy accuracy tend to make it a favorable instrument to use by machinist, tools designers, metalworkers, and quality inspectors

In this article, we will discuss several details that make the gauge a valuable tool, how it works, what applications it fits best for, and what professionals consider before actually choosing a gauge, such as the gauge range and differences between the radius set. Also, we will discuss how the price of the gauge varies depending on build quality and measurement requirements. By the end of this article, you should have a strong understanding of how to choose the best rated gauge for the precision measurement tasks you perform daily.

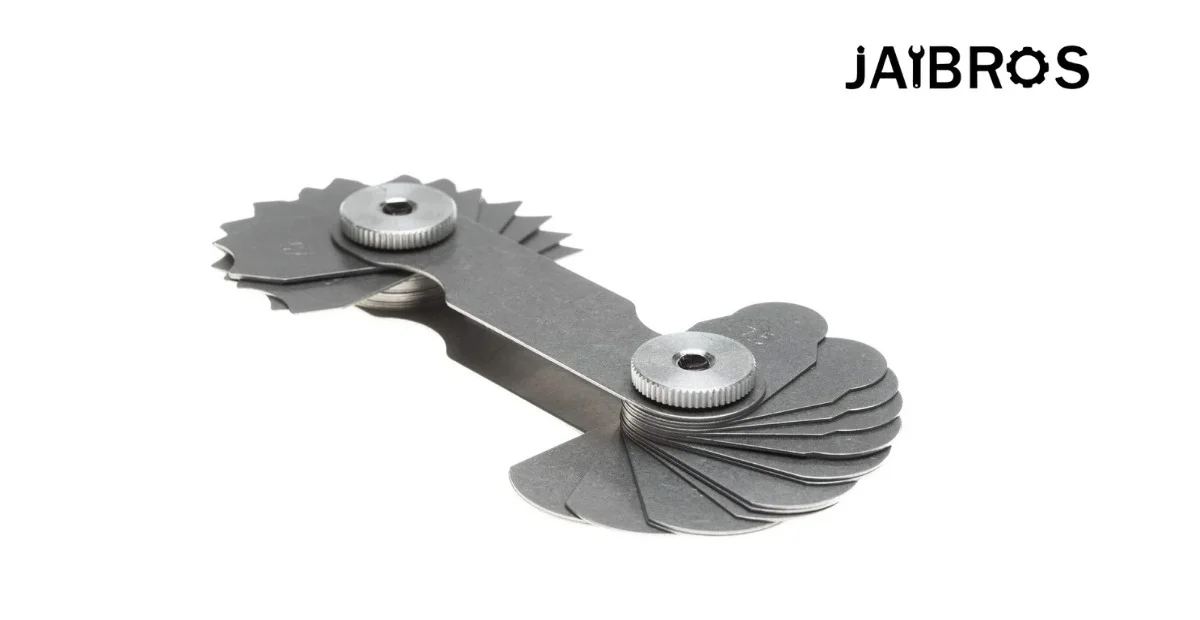

What Is a Radius Gauge?

A gauge is a measuring tool designed to check the radius of curved surfaces, both inward (concave) and outward (convex). Instead of relying on calculations or visual estimation, this tool provides instant verification of curvature size. It is commonly used in:

-

Tool rooms

-

Automotive workshops

-

Fabrication units

-

CNC machining centers

-

Metal and plastic component inspection

Manufactured in stainless steel with finely machined edges, the gauge consists of multiple leaves, each representing a fixed radius. This precision tool helps ensure that each component manufactured meets the required dimension with zero guesswork.

Why Accuracy Depends on the Right Gauge

In machining and fabrication, even a small deviation in curvature can lead to misalignment, improper fitting, or failure during assemblies. That’s why choosing the right gauge is essential for:

-

Maintaining dimensional accuracy

-

Achieving consistent quality

-

Reducing rework

-

Improving inspection productivity

Top-rated gauges are designed to withstand rough handling, resist bending, and maintain their edge accuracy over time. When paired with a well-defined gauge range, machinists can quickly match a radius without complicated measuring steps.

Understanding Radius Gauge Range

The gauge range is one of the most important factors to check before purchasing. It determines how small or large a radius the tool can measure. A typical set may cover radii like

-

0.5 mm to 6 mm

-

1 mm to 25 mm

-

0.010 in to 1 in (imperial versions)

Manufacturers offer various ranges based on industrial needs. A wider gauge range provides greater flexibility in verifying curved components, particularly in automotive, aerospace, and custom toolmaking industries.

Types of Radius Gauge Sets

Choosing the right gauge set depends on whether you work with small, medium, or large radii. Two main varieties are available:

1. Concave and Convex Combined Sets

These sets include leaves shaped to check both inward and outward curves. Their precision makes them ideal for general machining and routine inspection.

2. Specialized Sets for Small or Large Radii

For industries working on miniature components or heavy-duty machinery, dedicated sets are available. These sets ensure maximum accuracy within specific radius ranges.

Many professionals prefer owning more than one gauge set because it ensures they can measure a wide variety of parts without relying on rough estimation.

Factors That Affect Gauge Price

The gauge price varies depending on build quality, size range, brand, and material durability. A few key factors include:

1. Material Quality

Premium stainless steel gauges cost more because they resist corrosion and maintain measurement accuracy longer.

2. Manufacturing Precision

Leaf thickness accuracy and edge finishing directly influence the gauge price. Higher precision equals higher cost.

3. Number of Leaves and Range

A larger set covering more radii naturally costs more than a compact one.

4. Brand Reputation

Well-known brands that follow strict standards usually offer more reliable tools, which also reflects in the price.

Selecting the right tool involves balancing budget with measurement needs. A quality gauge is a long-term investment for any workshop.

Where Gauges Are Most Commonly Used

Industries that frequently depend on a gauge include:

-

CNC machining

-

Automotive part manufacturing

-

Mold and die making

-

Aerospace engineering

-

Fabrication units

-

Precision tool design

These gauges simplify inspection, reduce errors, and help maintain uniformity across batches—something every production facility values.

How to Use a Radius Gauge Correctly

Using the gauge is simple, but accuracy depends on correct technique. Here’s how professionals typically use it:

-

Clean the workpiece to remove dust or oil.

-

Select the leaf that matches the approximate radius.

-

Place it against the curve—both concave and convex edges if needed.

-

Check for gaps using a strong backlight.

-

Switch to another leaf if needed to achieve a perfect match.

This method ensures the measurement is verified without relying on visual assumptions.

Conclusion

A gauge remains one of the most trusted tools for accurate measurement of curved surfaces. From understanding the gauge to evaluating the right gauge set, professionals choose their tools carefully to achieve consistent results. Factors influencing gauge price, such as build quality and precision, also play an important role in selecting the best tool for the job.

About Jaibros:

Jaibros is a reliable industrial tools supplier offering a wide range of precision measuring instruments used in machining, engineering, and manufacturing applications. Their product selection helps users find tools suited to various accuracy and inspection needs.

FAQs

1. What is a radius gauge used for?

A radius gauge is used to measure and verify the curvature of concave and convex surfaces in machining and fabrication tasks.

2. How accurate is a radius gauge?

It is highly accurate because each leaf represents a fixed radius manufactured with precise tolerances.

3. What is the typical radius gauge range available?

Different sets may offer ranges like 0.5 mm to 6 mm, 1 mm to 25 mm, or larger depending on industrial needs.

4. Does the gauge price vary by material?

Yes, gauges made from premium stainless steel cost more because they offer better durability and long-term accuracy.

5. Why do machinists prefer a gauge set instead of a single gauge?

A set offers multiple radius options, making it easier to inspect different parts without limitations.