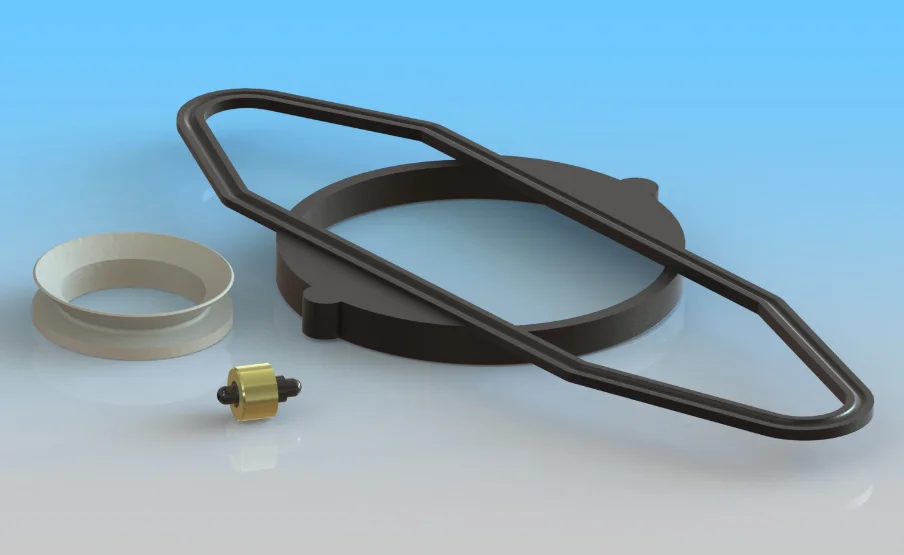

In the world of manufacturing and product design, custom molded shapes have become an essential solution for creating parts and components tailored to specific needs. These custom shapes are produced using a variety of materials, offering unparalleled flexibility and precision for industries ranging from automotive to medical to consumer goods.

What Are Custom Molded Shapes?

Custom molded shapes refer to parts or components that are designed and manufactured to specific shapes and sizes using a mold. These molds are often created from materials like metals, plastics, or rubber, and the molding process involves injecting or pouring the material into the mold to take the desired form. This process ensures that the final product meets the required specifications in terms of size, shape, and material properties.

The most common types of molding processes include:

- Injection Molding: A process where molten material is injected into a mold to create precise shapes.

- Compression Molding: Involves placing a material into a heated mold and applying pressure to form the shape.

- Blow Molding: Primarily used for making hollow plastic products by inflating the material inside a mold.

- Rotational Molding: Material is placed into a mold and then rotated to evenly distribute the material to form a shape.

Advantages of Custom Molded Shapes

-

Precision and Consistency Custom molded shapes offer a high level of precision, allowing manufacturers to create components that meet exact specifications. This consistency ensures that every product produced will have the same dimensions and performance characteristics, making them ideal for high-volume manufacturing.

-

Material Versatility Depending on the application, a variety of materials can be used for molding, such as thermoplastics, elastomers, metals, and composites. This versatility means that custom molded shapes can be designed to meet specific requirements, whether the product needs to be lightweight, durable, or resistant to extreme temperatures.

-

Complex Geometries One of the key benefits of custom molding is the ability to produce complex geometries that would be difficult or impossible to achieve through other manufacturing methods. Intricate shapes, textures, and internal features can be easily incorporated into the design, making it possible to create highly functional parts for specific applications.

-

Cost-Effective for High-Volume Production While the initial cost of creating a custom mold can be high, the long-term benefits of mass production make it cost-effective in the long run. Once the mold is created, thousands or even millions of parts can be produced quickly and efficiently, reducing the cost per unit and ensuring scalability.

-

Design Flexibility Custom molded shapes offer extensive design flexibility, allowing manufacturers to innovate and develop unique products. Whether you need to design a specific component to fit within a larger assembly or require unique aesthetic features, custom molding can meet these needs.

Applications of Custom Molded Shapes

Custom molded shapes are used across a wide range of industries, each requiring specialized parts that adhere to strict standards. Here are some key sectors where custom molding plays a crucial role:

-

Automotive Industry: Custom molded components are essential for manufacturing parts like dashboards, seals, gaskets, and bumpers. These components must be durable, lightweight, and designed to withstand a variety of environmental conditions.

-

Medical Devices: In the healthcare sector, custom molded shapes are used for medical instruments, housings for devices, and components like tubing or gaskets. Precision and the use of medical-grade materials are critical in this field.

-

Electronics: Many electronic devices require custom molded components, such as housings for circuit boards, connectors, or buttons. Custom molding can ensure that these parts meet the exact tolerances needed for reliable performance.

-

Consumer Goods: From packaging to the development of specialized accessories or custom-shaped items, molded parts are often integral to consumer goods products.

-

Aerospace and Defense: Custom molded parts used in aerospace applications must meet high-performance standards for extreme conditions, including temperature fluctuations, vibration, and high stress. The ability to produce lightweight, strong parts is essential for this industry.

Choosing the Right Molding Process

When deciding on the best molding process for your custom shape, there are several factors to consider:

- Material Requirements: What material properties are necessary for the application? For instance, if the part needs to be heat-resistant, certain molding processes and materials might be more suitable.

- Complexity of Design: If your design features intricate details or thin walls, you may opt for injection molding, which is ideal for high-precision shapes.

- Production Volume: For small runs or prototypes, processes like 3D printing or compression molding may be more efficient. For large-scale manufacturing, injection molding is typically the most cost-effective.

- Tolerance and Finish: If your part requires tight tolerances and a smooth finish, the molding process should be selected accordingly to ensure these requirements are met.

Conclusion

Custom molded shapes offer remarkable benefits for industries looking to produce highly specialized, high-quality parts in large quantities. From precise component designs to the ability to use a wide range of materials, the versatility of custom molding continues to revolutionize manufacturing across various sectors. As technology and materials science evolve, the potential for even more innovative custom molded shapes will continue to expand, providing solutions for increasingly complex design challenges. Whether for automotive, medical, aerospace, or consumer goods, custom molding is a crucial process driving modern manufacturing forward.