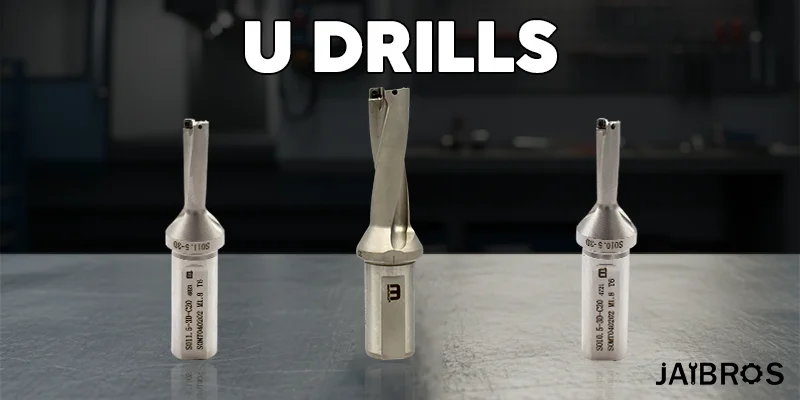

Boost machining speed and accuracy with advanced U drill technology. Learn about U drill size, U drill SPMG inserts, and U drill price to improve CNC drilling performance.

Upgrade Machining Performance with Advanced U Drill Technology

Improving machining productivity is a top priority for every manufacturer, and one of the most effective ways to achieve faster, cleaner, and more accurate drilling is by upgrading to the latest u drill technology. Modern drilling demands precision and consistency, and the right tool can dramatically reduce cycle times while improving hole quality. Whether you're handling mild steel, alloy steel, cast iron, or stainless steel, advanced drilling tools play a major role in efficiency.

In this blog, we explore how upgrading your machining setup with an advanced u drill can transform your drilling results, minimize tool wear, and boost overall output.

Why Modern U Drill Technology Matters

Traditional drilling tools often struggle with chip evacuation, inconsistent hole diameters, vibration, and excessive heat generation. Today’s improved u drill systems are designed to eliminate these challenges through advanced geometry, optimized coolant channels, and high-performance inserts.

These drills deliver high feed rates, deeper penetration, and clean finishes — making them ideal for CNC machining centers and high-volume production lines. Precise cutting edges, improved alignment, and robust body structures allow machinists to push speeds higher without compromising tool life.

Choosing the Right U Drill for Your Machine Shop

Selecting the correct u drill depends on various parameters like cutting depth, material hardness, insert compatibility, and spindle power. One of the most important considerations is u drill size, as the diameter and length directly affect stability and drilling accuracy. Ensuring the perfect u drill size will help eliminate vibration and maintain consistent hole quality even at high feed rates.

Compatibility with u drill spmg inserts is another crucial factor. The advanced u drill spmg insert design improves chip flow and reduces cutting forces, making drilling smoother and more reliable — especially during heavy-duty operations.

Understanding Cost vs. Value

Machinists often focus on u drill price, but the true value lies in durability, insert performance, and overall productivity gains. While comparing tools, it’s important to consider how often inserts need to be changed, how well the tool handles heat, and how effectively it maintains cutting accuracy.

In many cases, a slightly higher u drill price actually results in long-term savings due to improved performance, reduced downtime, and longer tool life.

Key Benefits of Upgrading to Advanced U Drill Technology

1. Faster Machining Cycles

An advanced u drill allows you to run higher feed rates without sacrificing precision. This means faster cycle times and higher output per shift.

2. Better Hole Quality

Thanks to improved drill body design and premium inserts, hole roundness, surface finish, and dimensional accuracy are significantly better.

3. Superior Chip Evacuation

Coolant-through systems and specialized flute geometries ensure chips don’t jam or scratch the hole walls.

4. Longer Tool Life

Modern drills dissipate heat effectively, keeping both the tool and inserts safe from rapid wear.

5. Reduced Machine Load

Designed for balanced cutting forces, these tools reduce stress on the spindle—prolonging machine life.

Conclusion

Upgrading your machining setup with an advanced u drill is a smart investment for any workshop looking to increase drilling efficiency, improve accuracy, and reduce operational costs. With careful selection of u drill size, compatibility with u drill spmg inserts, and understanding the true value beyond u drill price, manufacturers can significantly boost their machining performance.

FAQs

1. What materials can a U drill cut?

U drills can effectively cut mild steel, alloy steel, cast iron, stainless steel, and many non-ferrous metals.

2. Are U drills suitable for CNC machines?

Yes, U drills are specifically designed for CNC turning centers and machining centers for high-speed and high-precision drilling.

3. What inserts are commonly used with U drills?

Most U drills use SPMG or APKT inserts, depending on the drill design and application.

4. How do I select the right U drill size?

Choose a size that matches your required hole diameter and machine capability. Stability and feed rate capacity also depend on proper sizing.

5. Does a higher U drill price mean better quality?

Not always, but higher-quality drills often offer longer life, better accuracy, and reduced downtime — leading to cost savings over time.