Introduction

In 2025, lab grown diamonds officially reached 20% of total U.S. diamond sales, according to GIA data—a huge milestone showing how quickly the world is shifting toward ethical sparkle. Today, more people want jewellery that shines beautifully without the cost and environmental impact of mined stones.

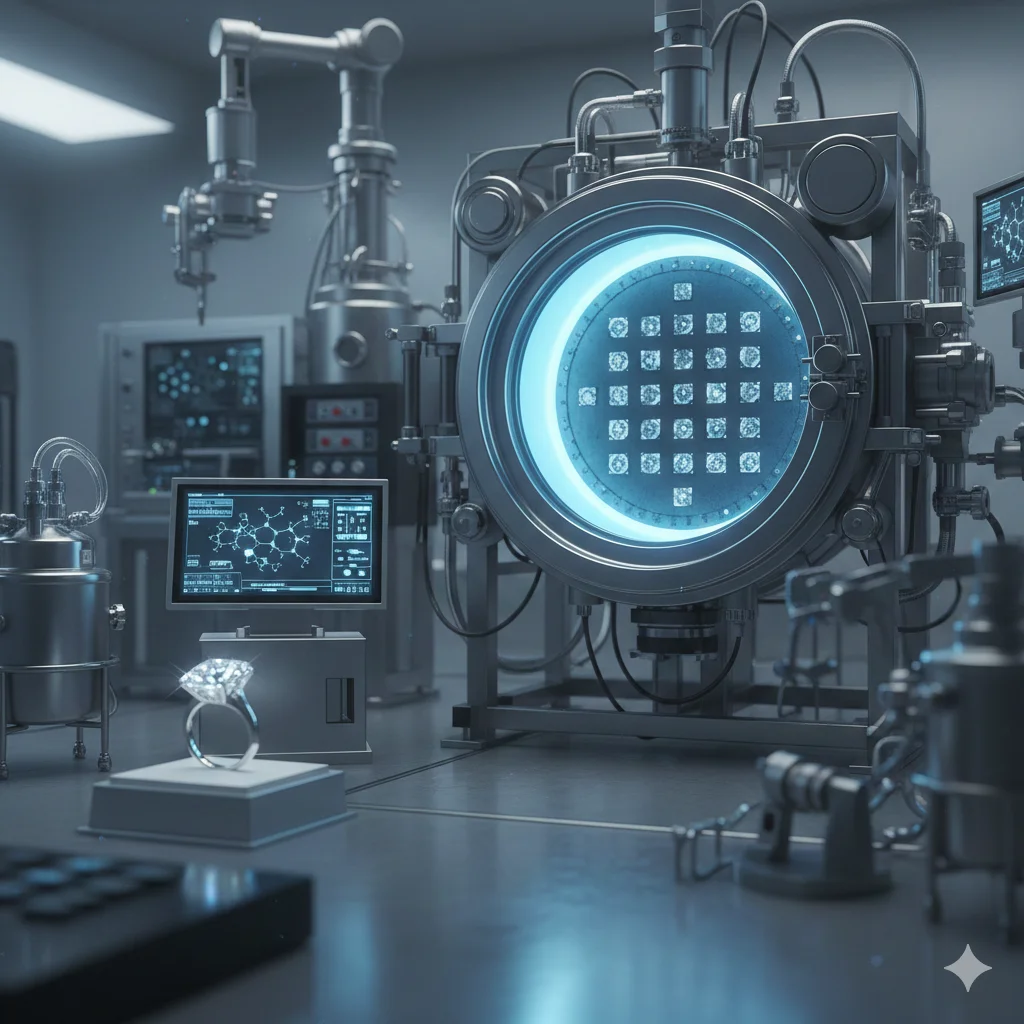

Two main technologies make this possible: CVD (Chemical Vapor Deposition) and HPHT (High Pressure High Temperature). These advanced methods grow diamonds under controlled lab conditions while maintaining the same carbon structure, hardness, and brilliance as natural gems. Even better, lab grown diamond jewellery often costs 30–40% less, making it a smart buy for modern shoppers.

In this blog, you’ll learn exactly how these diamonds are created—from the first seed to the final jewellery setting—plus expert insights and buyer-friendly tips to help you choose the best stones.

Lab Grown Diamonds: The Basics Before the Build

What Sets Them Apart From Mined Ones

Before diving into the CVD and HPHT steps, it’s important to understand what makes lab diamonds special:

-

They have the same carbon crystal structure as mined diamonds.

-

They offer the same sparkle, fire, and brilliance.

-

They rank 10 on the Mohs hardness scale, just like natural diamonds.

-

They are 100% chemically identical to diamonds formed in the Earth.

In short: Lab grown diamonds are real diamonds.

Why Choose Lab Methods?

Lab grown diamonds are becoming the top choice for buyers because they offer ethical, sustainable, and transparent production:

-

No mining means no harm to land or communities.

-

They avoid the heavy pollution caused by excavation.

-

They use cleaner manufacturing technologies.

A great real-world example:

Diamond Foundry, a well-known U.S. producer, powers its large-scale diamond facilities entirely with solar energy, creating some of the most eco-friendly diamonds in the world.

Expert Quote

Gemologist Dr. Jane Lee puts it perfectly:

“Lab gems let jewelers focus on design, not dirt.”

When diamonds are grown sustainably, creators can spend more time perfecting jewellery craftsmanship—and less time worrying about mining issues.

Step-by-Step: The CVD Process Explained

1. Seed Crystal Prep and Chamber Setup

CVD diamonds start with something very small: a thin diamond seed—usually a flat slice of a previously grown diamond.

Here’s how the process begins:

-

Tiny seed crystals are placed carefully inside a vacuum chamber.

-

Methane and hydrogen gases are added to the chamber.

-

The chamber is heated to around 1,800°F to begin carbon activation.

Pro Tip: Temperature control is the key to high-quality growth in CVD.

2. Atom-by-Atom Growth Phase

Once the chamber heats up, plasma energy breaks down the methane gas, releasing carbon atoms.

These carbon atoms slowly settle onto the diamond seed, bonding layer by layer.

This growth takes about 2–4 weeks, depending on the size of the diamond.

A real case study:

VRAI, a California-based producer, uses the CVD method to create 2-carat Type IIa diamonds, known for their exceptional purity.

3. Cool Down and Extraction

Once the diamond reaches the desired size:

-

The chamber cools slowly to prevent cracks.

-

The rough diamond—usually between 1 to 5 carats—is removed.

-

These stones are typically colorless and very clear, making CVD ideal for premium jewellery.

Step-by-Step: The HPHT Process Breakdown

While CVD is popular for high-clarity stones, HPHT remains one of the oldest and most reliable ways to create diamonds.

1. Starting With the Carbon Source

HPHT diamonds begin with a carbon-rich material such as:

-

Graphite, or

-

A metal-carbon mixture

This carbon is placed into a special press. Then:

-

Pressure reaches up to 1.5 million PSI

-

Temperature rises to nearly 2,600°F

This replicates the intense natural environment deep in the Earth’s mantle.

2. Crystal Formation Under Pressure

Under these extreme conditions, carbon atoms bond tightly and form a diamond crystal.

HPHT is excellent for creating fancy color diamonds such as yellow, blue, and pink.

Engineer Mark Chen explains:

“HPHT mimics Earth’s core for fancy colors.”

A real example:

IIa Technologies, one of the world’s leading lab producers, uses HPHT to grow Type IIa diamonds known for exceptional optical quality.

3. Release and Initial Cleaning

Once grown:

-

Diamonds are released from the press

-

They undergo an acid bath to remove leftover metal catalysts

-

They are weighed, sorted, and inspected

HPHT can produce larger stones faster than CVD, making it a top choice for big solitaire rings and premium lab grown diamond jewellery.

Turning Rough Diamonds into Stunning Jewellery

A rough lab diamond isn’t ready for your ring or pendant yet. It must undergo several stages of craftsmanship.

Cutting and Shaping the Stones

Expert cutters use advanced tools to transform the rough diamond into a polished gemstone:

-

Laser saws slice the diamond into the desired shape

-

Faceting begins—usually 58 facets for a round brilliant

-

The stone is polished until it reaches maximum shine

Tip: Always choose stones with Excellent or Ideal cut for the best brilliance.

Quality Checks and Grading

Once polished, the diamond is certified by reputed institutions like IGI or GIA.

Grading includes:

-

Cut

-

Color

-

Clarity

-

Carat weight

A real-world example:

Pandora’s lab diamond collection uses both CVD and HPHT stones, each graded to ensure high standards for daily-wear rings.

Setting Into Final Jewellery

Finally, the diamond is mounted into the jewellery piece of your choice:

-

Prong or bezel settings hold the stone securely

-

Gold, platinum, or lab-grown diamond studded frames are crafted

-

Jewelers ensure symmetry and durability

Actionable Tip: Check fluorescence under UV light; some buyers prefer “None” for the purest sparkle.

This final phase transforms science and craftsmanship into the jewellery you love.

Why Lab Grown Wins: Benefits and Smart Buying Tips

Cost, Ethics, and Eco Facts

Lab diamonds offer unbeatable advantages:

-

Save up to $4,000 on a 1-carat ring versus mined

-

Use 90% less water

-

Produce significantly lower carbon emissions

-

Come with transparent sourcing—no conflict funding

Common Myths Busted

Myth: Lab diamonds don’t hold resale value.

Truth: Today, certified lab diamonds resell well, especially high-quality CVD/HPHT stones from trusted brands.

Jeweler Alex Rivera advises:

“Buy certified CVD/HPHT for peace of mind.”

Actionable Buyer Checklist

Before purchasing lab grown diamond jewellery:

-

✔ Verify certification (GIA or IGI)

-

✔ Check the seller’s return and exchange policies

-

✔ Compare pricing from at least 3 vendors

-

✔ Look for transparency in the diamond’s growth process

-

✔ Ask about fluorescence and cut grade

Conclusion: Ready to Buy Lab Grown Sparkle?

Lab grown diamond jewellery blends modern science with stunning craftsmanship. From CVD’s slow crystal layering to HPHT’s high-pressure magic, every stone is created with advanced precision and ethical values.

Today’s market is growing fast—expected to hit $15 billion by 2026—making now the perfect time to explore the world of lab diamonds.

Use the buyer checklist above, choose certified stones, and enjoy jewellery that’s ethical, affordable, and brilliantly beautiful.