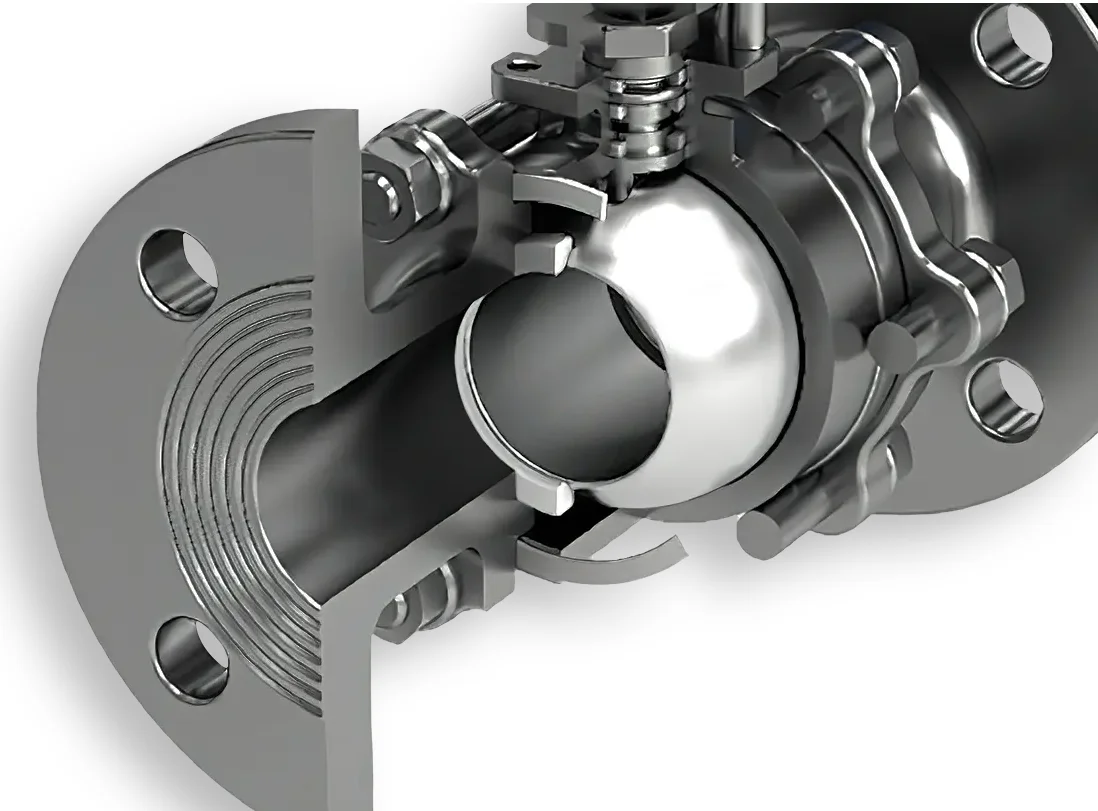

It always happens at the wrong time. A line is running at high load, operations are finally stable, and then a valve starts leaking, resisting movement, or losing sealing strength. Most engineers blame the external housing or the installation method, but in reality, many failures begin inside—at the Hard Seal Ball or the Custom Ball Valve Ball that’s doing the real work.

You can feel it coming long before it breaks:

A valve that used to move easily starts requiring two hands.

A seal that once felt firm begins slipping just slightly.

A cycle that should be smooth becomes rough, inconsistent, unpredictable.

Old Experience:

You slow down the system to avoid a complete shutdown.

You send maintenance to the same valve zone again and again.

You accept the constant interruptions because alternatives seem complicated.

You carry the stress of “will it hold today?” every time the system starts up.

New Experience:

The valve behaves the same on the 500th cycle as it did on the first.

Your team isn’t constantly revisiting the same trouble points.

You stop worrying about sudden pressure changes or aggressive flow.

Your operations feel calmer because the core component isn’t deteriorating behind the scenes.

This shift happens when the valve’s internal ball is built to withstand the unpredictable—heat spikes, abrasion, corrosive media, or sudden emergency shutoff actions. A reliable Hard Seal Ball or Custom Ball Valve Ball doesn’t ask you to change your process. It fits directly into the valve you already use, so your workflow remains familiar.

It simply removes the stress you’ve been silently carrying—because a strong valve core makes your entire system feel more trustworthy.

When the most stressful part of your operation becomes the most stable, everything around it improves.