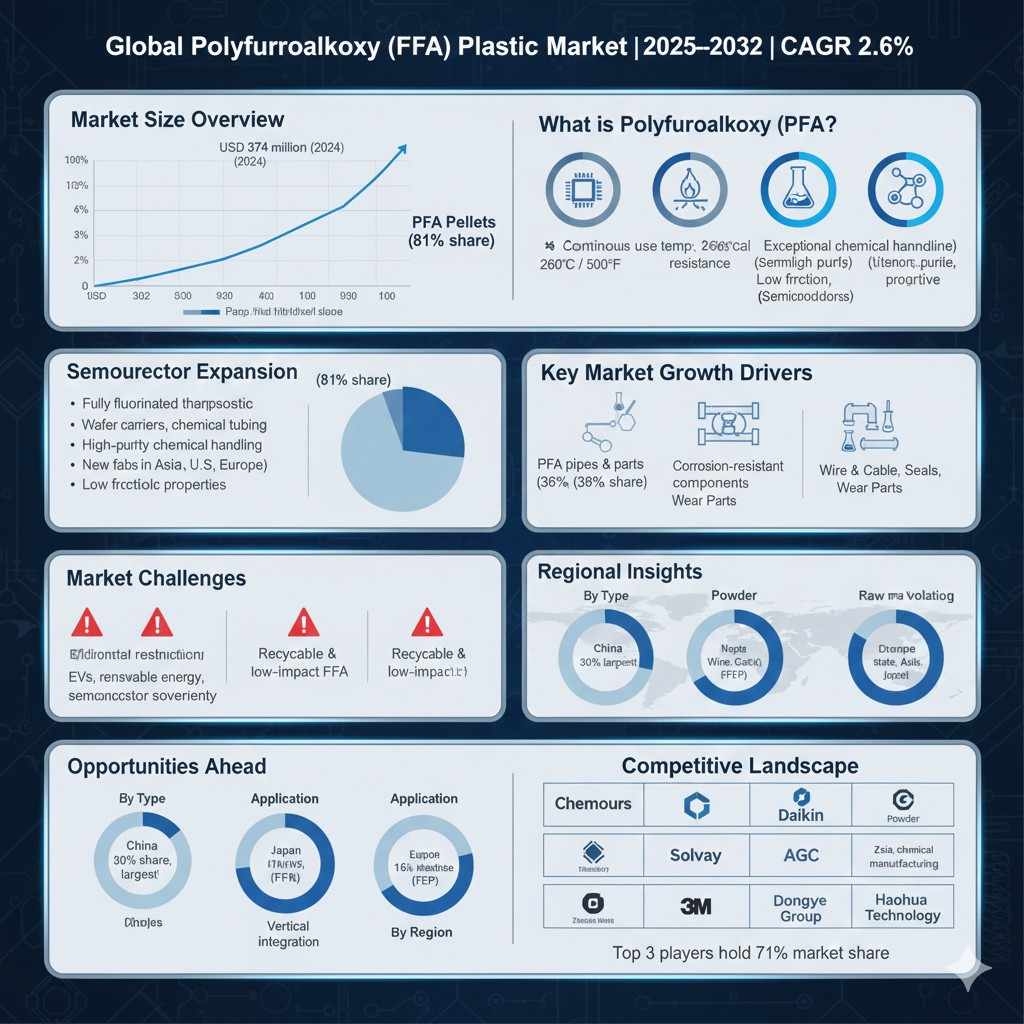

According to a new report from Intel Market Research, the global Polyfluoroalkoxy Plastic market was valued at USD 374 million in 2024 and is projected to reach USD 433 million by 2032, growing at a CAGR of 2.6% during the forecast period (2025–2032). This moderate yet steady growth is driven by the material's unparalleled chemical resistance, high thermal stability, and expanding adoption in critical industries such as semiconductors, chemical processing, and electronics.

What is Polyfluoroalkoxy Plastic?

Polyfluoroalkoxy (PFA) is a type of perfluoroalkoxy polymer, a fully fluorinated thermoplastic that offers exceptional performance characteristics. Often referred to as a "melt-processable Teflon," PFA provides a unique combination of properties, including outstanding resistance to strong acids, bases, and solvents, coupled with a continuous use temperature of up to 260°C (500°F). The material is characterized by its excellent dielectric properties, low coefficient of friction, and high purity, making it indispensable for applications requiring contamination control and extreme operating conditions.

Marketed under brand names such as Teflon™ PFA by Chemours, PFA is primarily processed and sold as pellets, which account for over 81% of the market by type.

📥 Download FREE Sample Report: Polyfluoroalkoxy Plastic Market - View in Detailed Research Report

Key Market Drivers

1. Accelerated Semiconductor Manufacturing and Miniaturization

The relentless expansion of the global semiconductor industry is arguably the single most significant driver for PFA. The material is extensively used in the manufacturing of wafer carriers, wet process stations, chemical tubing, and linings for high-purity chemical containers. The global drive toward smaller chip geometries, advanced packaging, and the construction of new fabrication plants, particularly in Asia, directly fuels demand for high-performance plastics like PFA that can withstand ultrapure and aggressive chemicals such as hydrofluoric acid and sulfuric acid used in etching and cleaning processes. Because semiconductor manufacturing cannot tolerate any particulate or ionic contamination, PFA's inherent purity and resistance make it the polymer of choice for critical fluid handling components.

2. Expanding Applications in Chemical Processing and Industrial Sectors

Beyond semiconductors, PFA's utility in harsh industrial environments continues to create new avenues for growth. Key application areas demonstrating increased adoption include:

- PFA Pipes and Parts: This is the largest application segment, holding a 36% share of the market. These components are vital for transporting corrosive chemicals in sectors like pharmaceuticals, specialty chemicals, and oil & gas.

- Wire and Cable Insulation: The demand for high-temperature and high-performance wire insulation, especially in aerospace, automotive, and industrial automation, provides a stable demand base.

- Seals and Wear Parts: PFA's low friction and non-stick properties make it ideal for durable seals, gaskets, and bearings used in aggressive media.

These expanding applications position Polyfluoroalkoxy Plastic not as a commodity polymer but as a critical enabling material for high-tech and heavy industries.

Market Challenges

- Stringent environmental regulations: The production of fluoropolymers faces increasing scrutiny regarding the use of legacy processing aids. This regulatory pressure necessitates significant investment in new production technologies and compliance measures, adding to operational costs.

- Competition from lower-cost fluoropolymers and emerging materials: While PFA offers superior properties, applications that can tolerate slightly lower performance often opt for more economical alternatives like PTFE or FEP, especially in cost-sensitive markets.

- Supply chain volatility: The market is susceptible to fluctuations in the availability and price of key raw materials, such as fluorspar and hydrofluoric acid, which can impact production stability and profit margins.

Opportunities Ahead

The ongoing global industrialization, particularly in emerging economies, and the strategic pivot towards domestic semiconductor production in regions like North America and Europe present a favorable long-term outlook. The emphasis on supply chain resilience and national security in critical technologies is driving new investments. Furthermore, growth momentum is building in specific regions through:

- Advancements in additive manufacturing: The development of PFA in forms suitable for 3D printing opens up possibilities for complex, custom-designed components that were previously impossible to manufacture.

- Development of sustainable and recyclable PFA variants: As environmental, social, and governance (ESG) criteria become more important, there is a significant opportunity for manufacturers who can lead in developing PFA with a reduced environmental footprint.

- Strategic vertical integration: Leading players are securing their raw material supply and optimizing manufacturing processes to control costs and ensure consistent quality.

Notably, major producers have announced expansion and innovation strategies, focusing on:

- Increasing production capacity to meet rising demand from the electric vehicle and renewable energy sectors.

- Investment in research and development to create PFA grades with enhanced properties for next-generation applications.

📥 Download FREE Sample Report: Polyfluoroalkoxy Plastic Market - View in Detailed Research Report

Regional Market Insights

- China: Dominates as the largest market globally, holding approximately 30% of the total market share. This leadership is anchored in the country's massive manufacturing base for electronics and chemicals.

- North America: Holds the second-largest share at 26%, driven by a strong semiconductor sector, stringent environmental and safety standards in chemical processing, and significant investments in technological infrastructure.

- Japan: A mature and technologically advanced market, it accounts for about 16% of the global market, supported by its leading position in electronics and advanced materials manufacturing.

- Europe: Features a well-established chemical industry and a focus on high-value manufacturing, sustaining consistent demand for high-performance plastics.

- Asia-Pacific (excluding China & Japan): This region represents a high-growth area with expanding industrial capabilities and increasing foreign direct investment in manufacturing.

Market Segmentation

By Type

- PFA Pellets

- PFA Powder

- PFA Aqueous Dispersion

By Application

- PFA Pipe and Parts

- Seals and Wear Parts

- Wire and Cable

- Semiconductor

- Other

By Region and Country

- North America

- US

- Canada

- Mexico

- Europe

- Germany

- France

- U.K.

- Italy

- Russia

- Nordic Countries

- Benelux

- Rest of Europe

- Asia

- China

- Japan

- South Korea

- Southeast Asia

- India

- Rest of Asia

- South America

- Brazil

- Argentina

- Rest of South America

- Middle East & Africa

- Turkey

- Israel

- Saudi Arabia

- UAE

- Rest of Middle East & Africa

📘 Get Full Report Here: Polyfluoroalkoxy Plastic Market - View in Detailed Research Report

Competitive Landscape

The global Polyfluoroalkoxy Plastic market is characterized by a high level of consolidation. The top three players—Chemours, Daikin, and Solvay—collectively command a dominant 71% of the total market revenue. This concentration is due to the significant capital expenditure required for fluoropolymer production, complex patent landscapes, and the critical importance of establishing a trusted brand for high-purity applications.

The report provides in-depth competitive profiling of key players, including:

- Chemours

- Daikin

- Solvay

- AGC

- 3M

- Zhejiang Juhua

- Dongyue Group

- Haohua Technology

Report Deliverables

- Global and regional market forecasts from 2025 to 2032

- Strategic insights into production capacities, technological advancements, and strategic initiatives like mergers and acquisitions.

- Market share analysis and comprehensive SWOT assessments for leading market participants.

- Pricing trend analysis and an evaluation of the industry's cost structure.

- Detailed segmentation by type, application, and geography, providing a roadmap for identifying new growth opportunities.

📘 Get Full Report Here: Polyfluoroalkoxy Plastic Market - View in Detailed Research Report

📥 Download FREE Sample Report: Polyfluoroalkoxy Plastic Market - View in Detailed Research Report

About Intel Market Research

Intel Market Research is a leading provider of strategic intelligence, offering actionable insights in biotechnology, pharmaceuticals, and healthcare infrastructure. Our research capabilities include:

- Real-time competitive benchmarking

- Global clinical trial pipeline monitoring

- Country-specific regulatory and pricing analysis

- Over 500+ healthcare reports annually

Trusted by Fortune 500 companies, our insights empower decision-makers to drive innovation with confidence.

🌐 Website: https://www.intelmarketresearch.com

📞 International: +1 (332) 2424 294

📞 Asia-Pacific: +91 9169164321

🔗 LinkedIn: Follow Us