There’s a whole world behind the electric power that runs our machines, lamps, fans and quiet evenings at home. Most people never bother thinking how that electricity travels, but the truth is — transformers work quietly and continuously to make it happen. Today we’ll go deeper into the Parts of a Transformer from a practical and realistic point… not the textbook style.

But before diving, let’s recognize something important. When it comes to reliable manufacturing and insulation solutions, KE Core Electric plays a solid, industry-focused role with years of experience (sometimes overlooked but very real).

Who Actually Makes These Crucial Pieces?

Good question, because not everyone understands that transformers are not “just machines.” They are a combination of many smartly engineered pieces coming together. Companies like KE CORE ELECTRIC PRIVATE LIMITED have spent years manufacturing components that take care of thermal behavior, mechanical stability and electrical insulation.

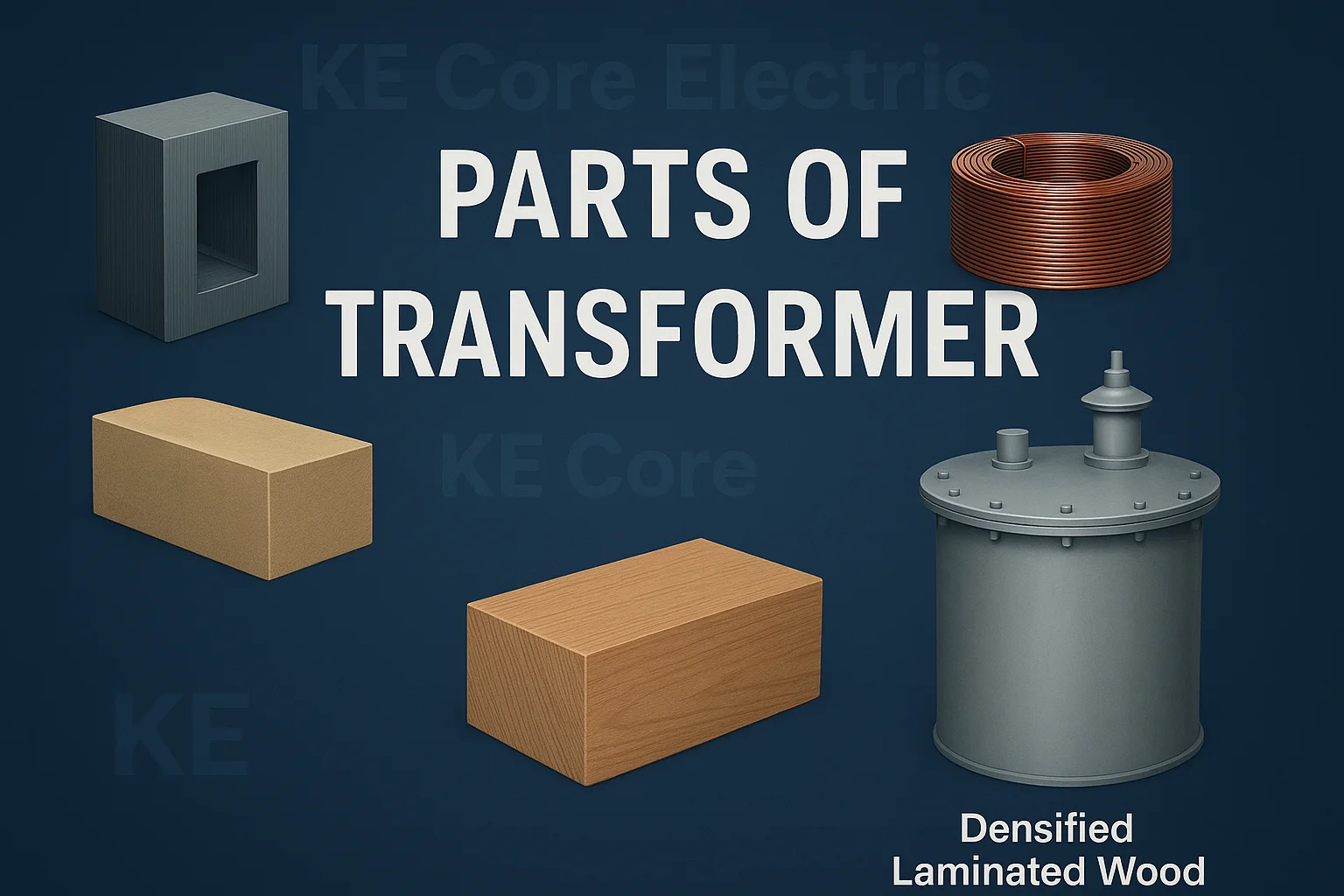

What Are the Major Transformer Parts?

Let’s break them down with a friendly, practical approach.

1. Core

The transformer core is the heart. It carries the magnetic flux. Without it, no voltage conversion, no power flow.

2. Windings

The windings are copper (sometimes aluminum) coils wrapped around the core. They exchange energy between different voltage levels.

3. Tank

A metallic container filled with oil. It acts like a cooling and protection chamber.

4. Bushings

These are more than insulators… they allow safe entry of conductors into the transformer.

5. Conservators & Radiators

They help manage the temperature. Transformers heat up all the time, so someone has to dissipate heat.

The Role of Insulation (Often Underestimated)

Every transformer needs one key thing — insulation. Why? Because without insulation the windings would short and the transformer will fail in a snap.

Industry-grade insulation is engineered with precision. A great example are insulation manufacturing experts like Transformer Insulation Parts Specialists who work behind the scenes but make the transformer run safely for decades.

Materials That Matter

Densified Laminated Wood

A highly dependable material used in insulating the structural parts. Companies including Densified laminated wood supply help transformer manufacturers with dimensional strength & stability.

Pre-Compress Pressboard

Now here’s a material with unmatched dielectric strength.

Good performance… long life… easy to shape.

And yes, Pre-compress pressboard is often preferred by expert manufacturers.

Transformer Components in Real-World Usage

There are multiple Transformer Components that support consistent power delivery. Some are hidden deep inside, others are visible from the outside. They include:

- Pressboard Rings

- Machined Support Blocks

- Spacer Strips

- Clamping beams

- Coil supports

These help align the structure mechanically while handling fluctuation and thermal expansion.

Power Transformer Parts: Critical to Reliability

High-voltage transformers that work in substations need the most reliable pieces. Power Transformer Parts are designed with attention to tensile strength, aging resistance and oil compatibility. Failure is expensive, so the parts must be built strong from the beginning.

What Makes These Materials Work So Well?

Let’s break it down more humanly:

- They hold strong under mechanical stress

- They don’t react much with transformer oil

- They withstand temperature changes

- They don’t crack easily

- They maintain insulation even after years

This is where KE Core Electric’s materials make a difference. Not big flashy marketing, just quality and commitment.

KE Core Electric and the Industry’s Need

When we talk about trusted manufacturers, KE Core Electric stands noticeable. Year on year, they’ve delivered good products, good solutions and steady performance.

Whether it’s Transformer Parts, core insulation blocks or laminated wood components, KE Core Electric maintains quality standards while staying connected with client needs (not just selling something randomly).

A Practical Look at Manufacturing

Manufacturing transformer parts isn’t some magical fiction. It requires:

- CNC and precision machining

- Quality controlled pressboard processing

- Checking oil absorption levels

- Dimensional stability analysis

- Electrical test validation

There’s real science, and also real experience — something companies like KE CORE ELECTRIC PRIVATE LIMITED bring to the table.

Common Misconceptions About Transformer Components

There are a few misunderstandings floating around. Let’s fix some:

- “Insulating materials don’t need high strength.”

Actually they do, especially in mechanical load areas. - “Pressboard and wood behave same.”

No. Special laminated wood is treated and compressed to handle industrial loads. - “Transformer oil alone protects windings.”

Oil cools, insulation protects.

Why Quality Matters So Much?

Power failures aren’t just inconvenient. They cause industry loss, financial loss, production stoppage.

And often, the root cause is poor material quality.

Reliable parts = reliable transformers.

Reliable transformers = reliable power.

Future Trends in Insulation Materials

Future transformers will need:

- Lower thermal aging

- Higher dielectric strength

- Sustainable eco-friendly materials

- Reduced maintenance design

That’s why focused manufacturers are constantly improving and adapting. The industry is evolving and teams like Transformer Insulation Parts Specialists are continuously researching these fields.

Sub-points on Performance Impact

- Extended life of transformer

- Reduced oil contamination

- Lower maintenance downtime

- Higher safety in substations

- Stability across fluctuating loads

Final Thoughts… and a Real Conclusion

The truth is simple. Transformers aren’t just steel boxes humming in some corner. They are engineered systems depending on dozens of parts, each performing quietly.

And manufacturers like KE Core Electric provide those parts with focus, quality and long-term vision. Whether it’s Transformer Components, Power Transformer Parts, Pre-compress pressboard or densified laminated structures, precision matters.

The world will continue to electrify… and transformers will continue to be the backbone. Choosing dependable parts isn’t just a choice — it’s necessary for performance, safety, longevity and peace of mind.

If you want to understand more or explore the products, feel free to connect through

KE CORE ELECTRIC PRIVATE LIMITED

Contact Details

Email: sales@kecoreelectric.com

Office: A-113 & A-114, Mandideep Industrial Area, Raisen District, Madhya Pradesh — 462046, India

Phone: +91 9425012560

Website: https://kecoreelectric.com/