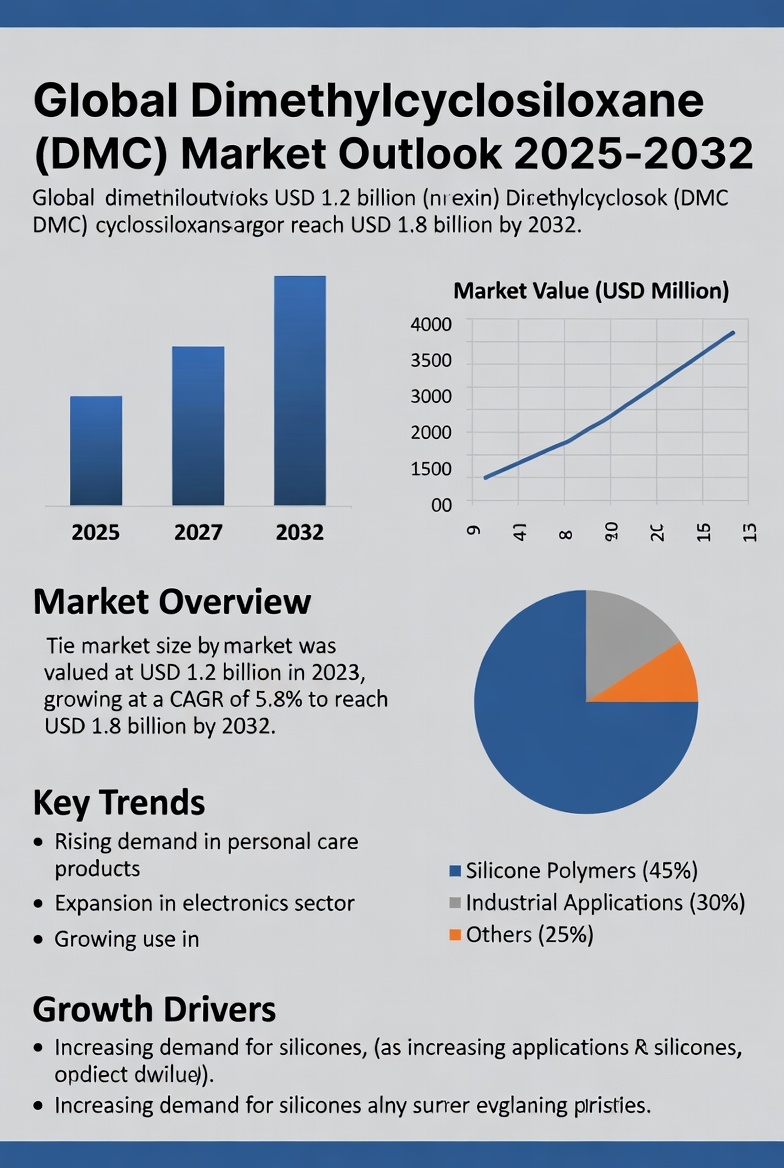

According to a new report from Intel Market Research, the global Dimethylcyclosiloxane (DMC) market was valued at USD 7,007 million in 2024 and is projected to reach USD 9,666 million by 2032, growing at a steady CAGR of 5.5% during the forecast period (2025–2032). This growth is driven by the expanding demand for silicone-based materials across construction, electronics, automotive, and healthcare industries, coupled with advancements in manufacturing processes and increasing applications in emerging sectors.

What is Dimethylcyclosiloxane (DMC)?

Dimethylcyclosiloxane (DMC) is a key cyclic siloxane compound primarily used as an intermediate in the production of silicone polymers. These polymers form the backbone of silicone-based materials, which are valued for their thermal stability, water repellency, electrical insulation, and flexibility. DMC serves as a crucial building block for manufacturing silicone elastomers, resins, fluids, and silane coupling agents, making it indispensable across a wide range of industrial applications.

Its role in enabling high-performance materials has established DMC as a critical component in sectors such as construction, electronics, transportation, and medical devices. The versatility and reliability of silicones derived from DMC contribute significantly to product innovation and efficiency in these fields.

📥 Download Sample Report: Dimethylcyclosiloxane (DMC) Market - View in Detailed Research Report

Key Market Drivers

1. Growth in Construction and Infrastructure Development

The construction industry remains a major consumer of silicone-based products, where DMC-derived materials are used in sealants, adhesives, and coatings due to their durability and resistance to environmental factors. Rapid urbanization, especially in Asia-Pacific and Middle Eastern regions, along with increased investment in smart infrastructure, is fueling demand. Government initiatives promoting sustainable and green buildings further bolster this trend, as silicone materials contribute to energy efficiency and longer lifecycle of structures.

2. Expansion of Electronics and Semiconductor Industries

DMC is essential in producing silicones used for encapsulation, thermal interface materials, and insulating components in electronic devices. The ongoing miniaturization of electronics, growth in 5G infrastructure, and rising adoption of Internet of Things (IoT) devices are key factors driving consumption. Additionally, the semiconductor industry's reliance on high-purity silicones for chip manufacturing underscores DMC's strategic importance in technological advancement.

3. Rising Automotive Production and Lightweighting Trends

In the automotive sector, silicone products made from DMC are used in gaskets, hoses, airbags, and vibration dampeners. The shift toward electric vehicles (EVs) and lighter, more efficient vehicles has increased the need for high-performance materials that withstand extreme temperatures and reduce overall weight. This trend is particularly prominent in regions with strong automotive manufacturing bases, such as North America, Europe, and Asia.

Market Challenges

- Environmental and Regulatory Scrutiny: Certain cyclic siloxanes face regulatory challenges due to concerns over persistence and potential environmental impact. Compliance with evolving regulations, such as REACH in Europe, requires significant investment in research and sustainable alternatives.

- Volatility in Raw Material Prices: Fluctuations in the prices of key raw materials, such as silicon metal and methanol, can impact production costs and profit margins for DMC manufacturers.

- Intense Market Competition: The presence of established global players and regional manufacturers creates a competitive pricing environment, necessitating continuous innovation and cost optimization.

Opportunities Ahead

The growing emphasis on sustainability and circular economy practices offers significant opportunities for innovation in silicone recycling and bio-based alternatives. Moreover, expansion in emerging economies across Asia, Latin America, and Africa presents untapped potential due to rising industrialization, urbanization, and investment in local manufacturing capabilities.

Recent developments include:

- Increased R&D focus on high-purity DMC for electronics and medical applications

- Strategic partnerships between silicone producers and end-use industries to develop customized solutions

- Investment in production capacity expansion by key players in high-growth regions to meet rising demand

📥 Download Sample PDF: Dimethylcyclosiloxane (DMC) Market - View in Detailed Research Report

Regional Market Insights

- Asia-Pacific: Dominates the global market, accounting for approximately 61% of market share, driven by robust manufacturing activity, infrastructure development, and electronics production in China, Japan, and South Korea.

- North America: Holds a significant share (~17%), supported by advanced technology sectors, automotive innovation, and stringent quality standards in medical and industrial applications.

- Europe: Accounts for about 15% of the market, with strong demand from automotive, construction, and personal care industries, alongside a well-established regulatory framework.

- Rest of the World: Regions such as Latin America and the Middle East & Africa are emerging as growth areas due to increasing industrial investment and economic development initiatives.

Market Segmentation

By Type

- Silicone Elastomer

- Silicone Resin

- Silicone Fluid

- Silane Coupling Agent

- Others

By Application

- Building

- Electronic Appliances

- Textile Industry

- Processing and Manufacturing

- Transportation

- Medical

- Power and New Energy

- Others

By Region

- North America

- Europe

- Asia-Pacific

- Latin America

- Middle East & Africa

📘 Get Full Report: Dimethylcyclosiloxane (DMC) Market - View in Detailed Research Report

Competitive Landscape

The global DMC market is characterized by the presence of several major players who collectively hold a significant market share. The top five companies account for approximately 59% of the market, indicating a moderately concentrated competitive environment. Key strategies include capacity expansion, technological innovation, and strategic mergers and acquisitions to strengthen market position and expand geographic footprint.

The report provides detailed competitive profiling of key players, including:

- Dow

- Wacker

- KCC

- Shin-Etsu

- Elkem Silicones

- Hoshine

- Dongyue Group

- Sanyou

- Wynca Group

- Xingfa

- Sucon

- YEIG

- Jinling

- Zhongtian

- Henngxing

- Luxi

Report Deliverables

- Global and regional market forecasts from 2025 to 2032

- Strategic insights into market dynamics, opportunities, and challenges

- Market share analysis and competitive landscape assessment

- Pricing trend analysis and supply chain evaluation

- Comprehensive segmentation by type, application, and geography

📘 Get Full Report: Dimethylcyclosiloxane (DMC) Market - View in Detailed Research Report

📥 Download Sample PDF: Dimethylcyclosiloxane (DMC) Market - View in Detailed Research Report

About Intel Market Research

Intel Market Research is a leading provider of strategic intelligence, offering actionable insights in biotechnology, pharmaceuticals, and healthcare infrastructure. Our research capabilities include:

- Real-time competitive benchmarking

- Global clinical trial pipeline monitoring

- Country-specific regulatory and pricing analysis

- Over 500+ healthcare reports annually

Trusted by Fortune 500 companies, our insights empower decision-makers to drive innovation with confidence.

🌐 Website: https://www.intelmarketresearch.com

📞 International: +1 (332) 2424 294

📞 Asia-Pacific: +91 9169164321

🔗 LinkedIn: Follow Us