The global Vapor Deposition market is experiencing robust expansion, fundamentally driven by the escalating demand for high-performance coatings in critical high-tech sectors like microelectronics, advanced tooling, and renewable energy. This comprehensive overview examines the market's size, share, key segments, competitive landscape, and provides a clear data forecast through 2029.

Market Overview of Vapor Deposition

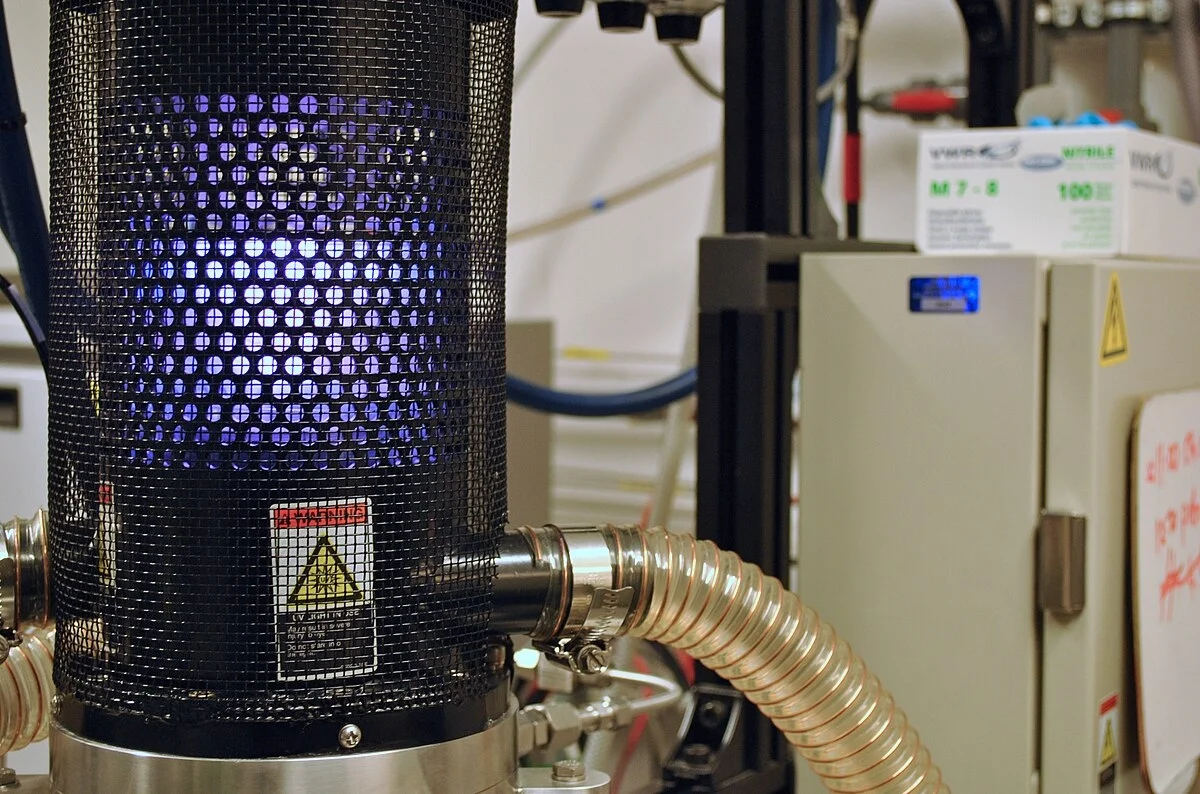

The vapor deposition process involves depositing thin films onto a substrate by condensing a vaporized material. This technology, encompassing techniques like Physical Vapor Deposition (PVD) and Chemical Vapor Deposition (CVD), is crucial for enhancing surface properties such as hardness, corrosion resistance, and electrical conductivity.

As per the analysis by Data Bridge Market Research, the vapor deposition market is projected for significant growth.

| Metric | 2021 Value | 2029 Forecast Value | CAGR (2022-2029) |

| Market Value (USD) | $27.81 billion | $47.60 billion | 6.95% |

The market is set to experience a Compound Annual Growth Rate (CAGR) of 6.95% during the forecast period, accelerating its market value to USD 47.60 billion by 2029.

For the forecast year 2025, other analyses focused on subsets of the market suggest robust figures:

Physical Vapor Deposition (PVD) Market Size in 2025: Estimated at approximately USD 25.58 billion or USD 29.41 billion.

Chemical Vapor Deposition (CVD) Market Size in 2025: Estimated at approximately USD 26.71 billion.

Get a Sample Report of Vapor Deposition Forecast @https://www.databridgemarketresearch.com/request-a-sample?dbmr=global-vapor-deposition-market

Key Market Segmentation of Vapor Deposition

The vapor deposition market can be segmented across various parameters, highlighting the diverse applications and technological sophistication of the industry.

1. By Technology/Type

The market is broadly divided into two primary segments:

Physical Vapor Deposition (PVD): This segment is favored for its versatility, lower temperature processing, and environmental friendliness. Key sub-processes include sputtering (like HiPIMS and Magnetron Sputtering), thermal evaporation, and arc deposition.

Chemical Vapor Deposition (CVD): Known for its ability to produce highly conformal films and high-purity materials, this includes Plasma-Enhanced CVD (PECVD), Low-Pressure CVD (LPCVD), and Atomic Layer Deposition (ALD) techniques. PECVD, in particular, is a major growth driver due to its application in semiconductor manufacturing.

2. By Application (The Advanced Thin Film Coatings)

The adoption of vapor deposition is directly linked to the need for advanced thin film coatings in high-growth industries:

Microelectronics/Semiconductors: This is the dominant application, where vapor deposition is essential for fabricating integrated circuits (ICs), memory chips, and display components. The demand is amplified by the proliferation of 5G, IoT devices, and miniaturization trends.

Cutting Tools: PVD coatings (like TiN, AlTiN) significantly increase the hardness, wear resistance, and lifespan of drills, molds, and machining tools.

Solar Products (Photovoltaic Cells): Thin-film solar cells rely heavily on vapor deposition techniques for efficient and cost-effective energy generation.

Medical Equipment: Biocompatible and anti-microbial coatings are applied to surgical tools and implants using vapor deposition processes.

Decorative Coatings: Used in the automotive, aerospace, and consumer goods industries for durable, aesthetic finishes (e.g., PVD colored stainless steel).

3. By Geography

The Asia-Pacific region holds the dominant market share, primarily due to the massive presence of semiconductor and electronics manufacturing hubs in countries like China, South Korea, Taiwan, and Japan. North America and Europe are also significant markets, driven by established aerospace, medical device, and R&D activities.

Do you have any specific queries or need any Vapor Deposition Submit your inquiry here @https://www.databridgemarketresearch.com/inquire-before-buying?dbmr=global-vapor-deposition-market

Key Players in the Vapor Deposition Market

The market is characterized by intense competition among global players focusing on R&D for more efficient, precise, and high-throughput deposition equipment and materials. Key companies shaping the competitive landscape include:

· IHI HAUZER B.V. (Netherlands)

·

· IHI Ionbond AG (Switzerland)

·

· Applied Materials Inc. (U.S.)

·

· Adeka Corporation (Japan)

·

· Plasma Therm (U.S.)

·

· Aixtron SE (Germany)

·

· Tokyo Electron Limited (Japan)

·

· IHI Group (Japan)

·

· Lam Research Corporation (U.S.)

·

· Kurt J. Lesker Company (U.K.)

·

· Veeco Instruments (U.S.)

·

· Oerlikon Balzers Coating AG (Switzerland)

·

· ULVAC (U.S.)

·

· ASM International (Netherland)

·

· JUSUNG ENGINEERING (South Korea)

·

· Aurora Scientific Corp. (Canada)

Market leaders are strategically focusing on mergers, acquisitions, and technological advancements, such as the adoption of Atomic Layer Deposition (ALD) for ultra-thin, highly uniform films, to gain a competitive edge.

Key Growth Drivers and Trends

Semiconductor Industry Boom: The relentless demand for smaller, faster, and more powerful electronic devices fuels the need for extremely precise and advanced deposition techniques.

Rising Demand for PV Cells: Global shifts toward renewable energy, bolstered by supportive government regulations, are accelerating the use of vapor deposition in solar panel manufacturing.

Technological Advancements: Innovation in low-temperature processes like PECVD and the emergence of High-Power Impulse Magnetron Sputtering (HiPIMS) are expanding the range of coatable materials and substrates.

Environmental Regulations: The environmentally conscious nature of PVD, which is often a cleaner alternative to traditional coating methods like electroplating, drives its increased adoption across various industries.

Get A Buy Now Report Vapor Deposition Forecast @https://www.databridgemarketresearch.com/checkout/buy/global-vapor-deposition-market/compare-licence

Future Outlook

The Vapor Deposition market is poised for robust and sustained growth, projected to achieve a market value of USD 47.60 billion by 2029 at a CAGR of 6.95%. This expansion is fundamentally underpinned by the rising global demand for advanced thin film coatings in the high-growth microelectronics and semiconductor sector, coupled with increased adoption in the medical, automotive, and renewable energy industries. The competitive landscape is dominated by key players continually innovating to meet the stringent performance and purity requirements of modern technological applications. The continuous evolution of PVD and CVD technologies, especially for nanoscale fabrication, solidifies vapor deposition's critical role in the future of advanced manufacturing.

About Us:

Data Bridge is one of the leading market research and consulting agencies that dominates the market research industry globally. Our company's aim is to give clients the knowledge they require in order to function in changing circumstances. In order to give you current, accurate market data, consumer insights, and opinions so that you can make decisions with confidence, we employ a variety of techniques, including surveys, video talks, and focus groups around the world.

Contact :

Data Bridge Market Research Private Ltd .

3665 Kingsway - Suite 300 Vancouver BC V5R 5W2 Canada

+1 614 591 3140 (US)

+44 845 154 9652 (UK)

Email: Sales@databridgemarketresearch.com

Website: https://www.databridgemarketresearch.com