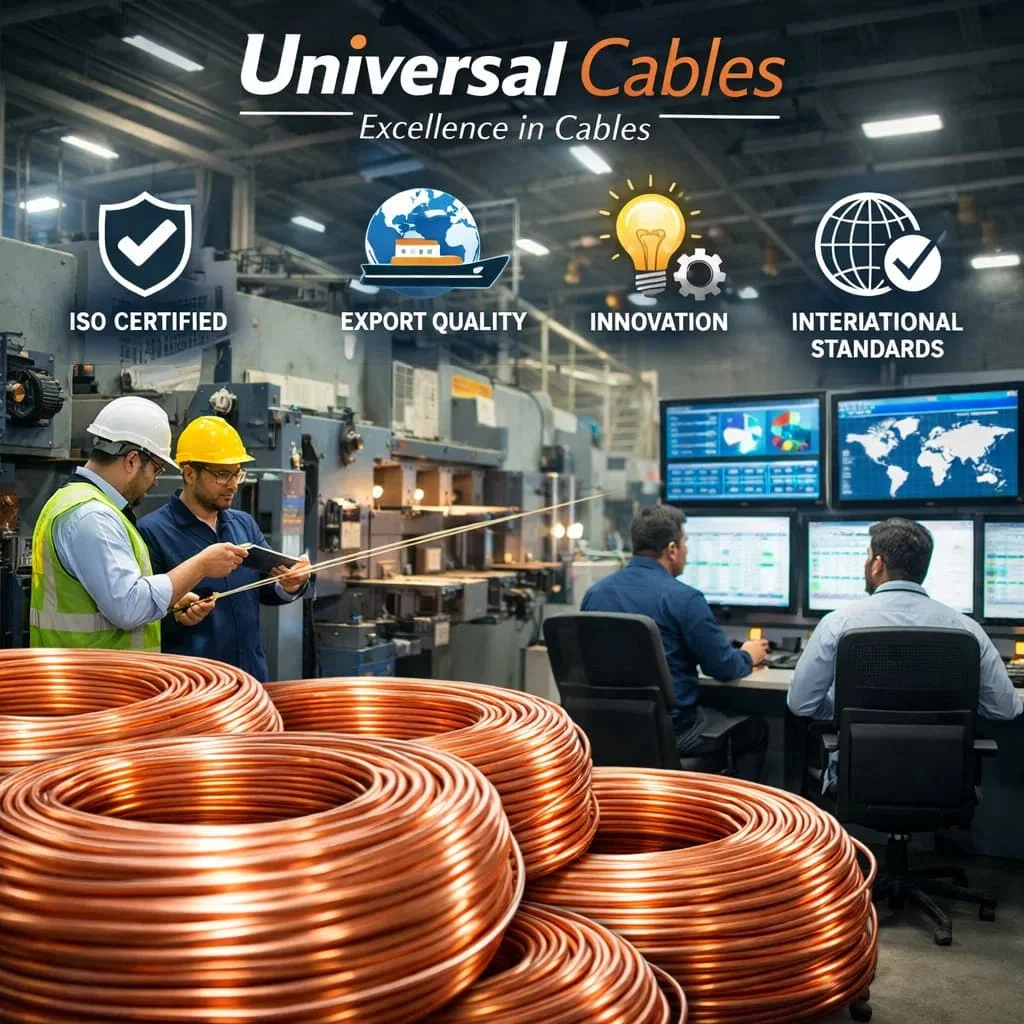

How Are International Cable Standards Met in Pakistan’s Manufacturing Sector?

The Growing Importance of International Cable Standards

The global demand for safe, efficient, and reliable electrical infrastructure continues to grow as economies expand and technology becomes more integrated into everyday life. From residential buildings to industrial facilities and renewable energy projects, electrical cables form the backbone of modern power distribution systems. In this context, international cable standards play a critical role in ensuring safety, performance, and long-term reliability.

For electric cable manufacturers in Pakistan, aligning with international standards is no longer optional—it is a necessity. Compliance not only safeguards end users but also strengthens market credibility, supports exports, and enhances competitiveness in regional and global markets. Pakistan’s cable manufacturing sector has evolved significantly over the years, adopting structured quality systems, advanced testing methods, and standardized production processes. This transformation reflects a broader commitment to meeting global benchmarks while supporting national infrastructure development.

Understanding International Cable Standards

International cable standards are technical specifications developed by recognized global bodies to ensure electrical products meet minimum safety, performance, and quality requirements. These standards define parameters such as conductor material quality, insulation thickness, voltage ratings, thermal resistance, and mechanical strength.

Common global benchmarks used in cable manufacturing focus on fire resistance, electrical conductivity, durability, and environmental performance. Compliance with these standards helps prevent electrical hazards such as overheating, short circuits, and power losses. For manufacturers, adherence to international standards builds trust among regulators, contractors, and consumers, ensuring products are accepted across diverse markets. Ultimately, standards serve as a universal language of quality, allowing products to perform consistently under varied operating conditions.

Regulatory Framework Governing Cable Manufacturing in Pakistan

Pakistan’s cable manufacturing industry operates within a structured regulatory framework designed to promote safety and quality. Local regulatory authorities oversee compliance with national electrical codes, while encouraging alignment with international standards. Certification bodies and inspection agencies play a vital role in verifying that products meet established technical requirements.

National regulations are increasingly harmonized with global benchmarks, enabling manufacturers to compete in export-oriented markets. This alignment supports consistent quality assurance across production stages, from raw material sourcing to finished product testing. For electric cable manufacturers in Pakistan, regulatory compliance reinforces accountability, ensures transparency, and contributes to overall industry stability.

Manufacturing Processes Aligned with Global Standards

Meeting international standards begins with disciplined manufacturing processes. High-quality raw materials, particularly pure copper conductors and reliable insulation compounds, are selected through stringent quality control procedures. Controlled production environments help maintain consistency, reducing the risk of defects during extrusion, stranding, and insulation stages.

Standardized workflows ensure precision in conductor dimensions, insulation thickness, and cable design. Automation and process monitoring systems further enhance accuracy and repeatability. By integrating modern manufacturing techniques, electric cable manufacturers in Pakistan are able to produce cables that meet global performance expectations while maintaining efficiency and scalability.

Quality Testing and Independent Certification Procedures

Quality testing is a cornerstone of standards compliance. Independent laboratories play a crucial role in evaluating cable performance through electrical, mechanical, and environmental tests. These assessments verify parameters such as voltage endurance, insulation resistance, heat tolerance, and mechanical strength.

Products that successfully pass these evaluations are issued certificates of conformity in line with international standards. Third-party validation adds an extra layer of credibility, assuring stakeholders that products meet objective quality benchmarks. For manufacturers, independent certification not only demonstrates compliance but also enhances reputation and market confidence.

Consistency and Continuous Improvement in Cable Production

Consistency in cable performance is essential for electrical safety and system reliability. Manufacturers invest significant resources in monitoring production parameters to ensure uniformity across batches. Continuous improvement strategies focus on identifying and eliminating inconsistencies that could impact quality.

Regular performance audits, process reviews, and feedback mechanisms help refine production methods over time. By embedding continuous improvement into operational culture, manufacturers achieve long-term efficiency gains and deliver dependable products to end users. This approach benefits both producers and consumers by reducing failures and extending product lifespan.

Compliance in Low Voltage Cable Manufacturing

Low voltage cables are widely used in residential, commercial, and light industrial applications, making safety and reliability critical. In Pakistan, low voltage cables in Pakistan must meet strict requirements related to insulation integrity, current-carrying capacity, and fire safety.

Manufacturing practices emphasize precise conductor sizing, high-quality insulation materials, and rigorous testing protocols. Compliance with international standards ensures that low voltage systems operate efficiently, minimizing risks of electrical faults. For everyday electrical infrastructure, adherence to standards protects property, equipment, and human life.

Meeting Standards for DC Solar Cable Production

The rapid growth of renewable energy has increased demand for specialized cables designed for solar power systems. Dc solar cables in Pakistan must withstand harsh outdoor conditions, including high temperatures, UV exposure, and moisture.

International standards for solar cables specify enhanced insulation, resistance to environmental stress, and long-term electrical stability. Manufacturers adopt advanced materials and testing methods to ensure durability and performance. Compliance with these standards supports the reliability of solar installations, contributing to sustainable energy generation and reduced system downtime.

Skilled Workforce and Technological Advancements

A skilled workforce is fundamental to maintaining manufacturing excellence. Trained professionals ensure that production processes adhere to technical specifications and quality benchmarks. Ongoing training programs help workers stay updated with evolving standards and technologies.

Technological advancements such as automated production lines, digital monitoring systems, and precision testing equipment further support compliance. Innovation enables manufacturers to improve efficiency, reduce waste, and enhance product quality. Human resource development, combined with modern technology, provides a strong competitive advantage in the cable manufacturing sector.

Industries Benefiting from Standard-Compliant Cable Manufacturing

Standard-compliant cables support a wide range of industries. Residential and commercial infrastructure relies on safe electrical distribution systems. The construction and industrial sectors depend on durable cables for heavy-duty applications.

Automotive, solar energy, IT, and data centers require specialized cables that meet strict performance standards. By supplying reliable products, electric cable manufacturers in Pakistan contribute to operational safety, energy efficiency, and system reliability across multiple sectors. Standards compliance ensures that cables perform consistently under demanding conditions.

The Global Impact of Standards Compliance in Pakistan’s Cable Industry

Meeting international standards enhances export potential by enabling manufacturers to access global markets. Compliance builds trust with international partners, contractors, and regulatory bodies. It signals a commitment to quality, safety, and professionalism.

For Pakistan’s cable industry, standards compliance supports long-term growth and competitiveness. It strengthens the country’s reputation as a reliable manufacturing hub and contributes to national infrastructure development. By aligning with global benchmarks, manufacturers position themselves for sustainable expansion in an increasingly interconnected market.

Conclusion: Strengthening Pakistan’s Position in the Global Cable Market

International cable standards play a vital role in shaping the quality and reliability of electrical products. Through structured manufacturing processes, rigorous testing, independent certification, and continuous improvement, electric cable manufacturers in Pakistan effectively meet these standards.

Consistency, skilled labor, and technological innovation remain key drivers of success. As demand grows for low voltage cables in Pakistan and dc solar cables in Pakistan, adherence to international benchmarks will continue to support safety, efficiency, and sustainability. Looking ahead, sustained commitment to quality and compliance will strengthen Pakistan’s position in the global cable manufacturing industry and support long-term economic development.