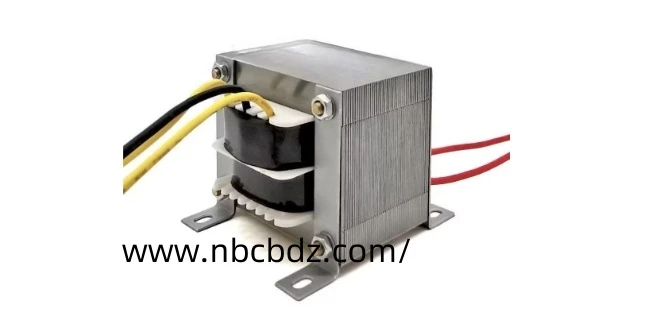

In a changing industrial landscape, the idea of Chuangbiao EI Transformer Factory often represents more than a place of production; it reflects a mindset of steady engineering and careful coordination. Within this context, the brand Nbcbdz has built its identity around balance, consistency, and application awareness. Rather than chasing trends, the focus stays on understanding how components quietly support wider systems, where reliability, material selection, and process discipline matter every day.

Transformers rarely take the spotlight, yet they influence how equipment behaves across varied environments. From assembly lines to integrated devices, these components must align with electrical expectations, mechanical space, and thermal conditions. This alignment is not accidental. It grows from structured workflows, clear communication between teams, and respect for practical use scenarios. When production thinking stays close to application reality, outcomes feel natural rather than forced.

Manufacturing culture plays a central role here. A calm, methodical approach allows teams to notice small details that might otherwise be missed. Winding techniques, insulation choices, and core treatment all benefit from attention and patience. Over time, this creates a rhythm where quality control becomes a habit rather than a checkpoint. Such environments value repeatability and clarity, which helps partners plan with confidence.

Another important aspect is adaptability. Industries shift, product designs evolve, and requirements change. A factory that listens carefully can adjust without losing its foundation. This does not mean constant reinvention, but thoughtful refinement. By staying open to dialogue and feedback, manufacturers can support diverse projects while keeping internal processes stable. This balance often defines long term cooperation.

Sustainability, in a practical sense, is also part of modern expectations. Material efficiency, process optimization, and waste awareness are no longer optional considerations. They influence cost structure, operational flow, and environmental responsibility. When these elements are treated as part of daily decision making, they naturally integrate into production outcomes rather than appearing as add ons.

Communication completes the picture. Clear exchanges between designers, engineers, and production teams reduce misunderstandings and delays. When questions are addressed early, solutions feel smoother and timelines remain manageable. This cooperative tone often shapes how clients experience a manufacturing partner, not just through products, but through the entire collaboration journey.

Ultimately, transformers may remain unseen once installed, but the thinking behind them leaves a lasting impression. Careful manufacturing supports stability in countless applications, quietly enabling systems to function as intended. This understated role is what gives the field its lasting relevance.

If you are curious how these ideas come together in practice, consider taking a closer look. A well designed digital doorway can reveal more than expected. Step into the details, stories, and possibilities waiting at https://www.nbcbdz.com/product/ , and see where thoughtful manufacturing conversations might lead next.