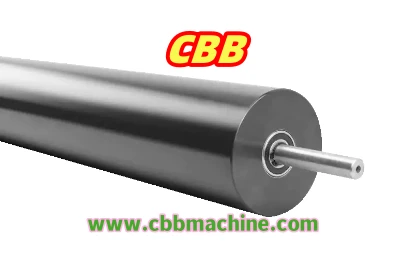

Within modern production environments, the Aluminum Roller represents a balance between lightweight construction and steady operation, and at Cbbmachine it reflects a broader approach to practical engineering. Rather than drawing attention to itself, this component quietly supports continuous movement, helping materials travel smoothly through complex processes while maintaining alignment and surface consistency.

Manufacturing lines today rely on rhythm. When motion feels predictable, operators can focus on quality instead of constant adjustment. A well-designed roller contributes to this rhythm by reducing unnecessary resistance and encouraging stable material flow. Its structure allows it to integrate naturally into different stages of production, whether guiding films, supporting webs, or assisting in surface treatment processes.

Another important aspect lies in adaptability. Production demands rarely remain static, and equipment must respond without disruption. Rollers made from aluminum-based structures offer a balance that suits varied operational needs. They can be customized in surface finish or internal configuration, allowing them to match specific handling requirements without altering the surrounding system.

Consistency also influences long-term efficiency. When material moves evenly, downstream processes benefit from fewer interruptions and less corrective work. This steadiness can influence coating uniformity, printing clarity, and overall process confidence. Over time, such stability supports a calmer working environment where machines and operators interact with fewer surprises.

Maintenance considerations further shape equipment choices. Components that are easy to inspect and care for tend to remain in service longer and perform more predictably. A thoughtfully produced roller supports routine upkeep without demanding complex procedures, aligning with facilities that value order and continuity in daily operations.

Across industries such as packaging, converting, and material processing, rolling elements serve as connectors between ideas and execution. They translate design intent into physical movement, ensuring that materials behave as expected. When each part fulfills its role quietly and reliably, the entire production line feels more coherent.

If these reflections on industrial motion spark your interest, consider following that curiosity a step further. A visit to https://www.cbbmachine.com/news/industry-news/everything-you-need-to-know-about-aluminum-roller.html may reveal perspectives and solutions that align naturally with how you envision your next manufacturing chapter.