Custom embroidered patches are widely used across industries for branding, identification, and decoration. From corporate logos and uniforms to fashion items and promotional products, patches offer durability and long-term value.

However, the final quality of an embroidered patch depends largely on one critical step: digitizing. Professional patch digitizing services ensure that artwork is accurately converted into embroidery files that machines can execute with precision and consistency.

Understanding Patch Digitizing

Patch digitizing is the technical process of converting logos, illustrations, or text into a stitch-based embroidery file. This file defines stitch types, directions, densities, and sequencing so embroidery machines can reproduce the design correctly. Patch digitizing differs from regular embroidery digitizing because patches require stronger borders, complete stitch coverage, and added durability.

Experienced digitizers understand how embroidery behaves on different patch bases and backings. Their practical knowledge ensures the final patch maintains shape, clarity, and structural integrity after stitching, trimming, and application.

Why Professional Patch Digitizing Is Important

Inaccurate digitizing can lead to thread breaks, uneven stitching, poor edge definition, and distorted artwork. These issues increase production costs and result in inconsistent patches. Professional patch digitizing services help eliminate such problems by applying proven techniques and quality control measures.

Working with skilled digitizers offers clear advantages, including accurate stitch placement, balanced stitch density, clean borders, and machine-ready files that perform consistently during production. This level of precision is especially important for patches produced in bulk or used for professional branding.

Essential Elements of High-Quality Patch Digitizing

Creating a durable and visually clean patch requires careful planning beyond basic artwork conversion. Professional digitizers focus on multiple technical elements to ensure reliable results.

Border construction is a key factor. Whether using merrow, satin, or run stitch borders, precise digitizing helps maintain the patch shape and prevents fraying during use.

Stitch direction and flow influence how light reflects off the thread, affecting texture and readability. Proper stitch angles ensure a balanced and professional appearance.

Thread coverage must be complete so the base fabric does not show through, particularly for patches intended for long-term wear.

Scalability ensures the design remains legible and proportional when resized for different patch dimensions.

Fabric and backing considerations are also addressed during digitizing to provide stability and prevent distortion during stitching.

Types of Patches That Require Professional Digitizing

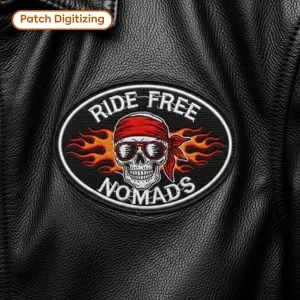

Professional patch digitizing services support a wide range of patch styles, each requiring specific technical handling. Common patch types include logo patches, name or identification patches, badges, decorative fashion patches, sports team patches, and promotional patches. Each category demands accurate stitch planning to ensure durability, clarity, and production efficiency.

Benefits for Businesses and Organizations

For businesses, professional patch digitizing is both a quality and operational advantage. Well-digitized files reduce embroidery machine errors, shorten production time, and minimize material waste. This results in consistent branding and reliable output across repeated orders.

Businesses also benefit from patches that maintain their appearance after washing and regular use, which supports brand credibility and customer trust. Whether producing small runs or large quantities, professionally digitized patches help maintain consistent standards.

How Professionals Prepare Designs for Embroidery

Not all artwork is suitable for embroidery in its original form. Professional digitizers analyze designs and make necessary adjustments while preserving brand identity. Fine details may be refined, overlapping elements simplified, and color selections optimized for thread performance.

These refinements help ensure the design remains readable when stitched, stitch counts are optimized for efficiency, and the final patch accurately represents the intended design. This process relies on hands-on experience and technical understanding that automated software often lacks.

Choosing a Reliable Patch Digitizing Service

Selecting the right digitizing provider is essential for dependable results. A professional service typically offers manual digitizing by trained experts, multiple embroidery file formats, quality checks before delivery, revision support, and dependable turnaround times. These factors help ensure smooth production and consistent patch quality.

Final Thoughts

Professional patch digitizing services form the foundation of high-quality embroidered patches. By combining technical skill with practical embroidery experience, professional digitizers create files that deliver clean stitching, durability, and consistency. For branding, uniforms, fashion, or promotional use, investing in expert digitizing helps ensure reliable results and long-term value.

Frequently Asked Questions

What makes patch digitizing different from regular embroidery digitizing?

Patch digitizing focuses on strong borders, full stitch coverage, and durability, as patches are produced separately and applied later.

Can any image be used for patch digitizing?

Most images can be digitized, but designs may need adjustments to ensure clean stitching and readability.

Why is manual digitizing preferred for patches?

Manual digitizing allows precise control over stitch placement and density, resulting in better quality than automated conversions.

Do professionally digitized patches last longer?

Yes, accurate digitizing improves stitch stability and helps patches maintain their appearance through wear and washing.