Introduction

Last year, a small machine shop lost almost $10,000 in one month.

The problem was simple. Their parts kept slipping inside the chuck. A weak jaw grip caused bad cuts, scrap parts, and machine downtime. Operators had to stop work again and again to reset the part.

All because they chose the wrong Hard Jaws.

This raises an important question for every shop owner:

Should you save money now with standard jaws or invest more for custom precision later?

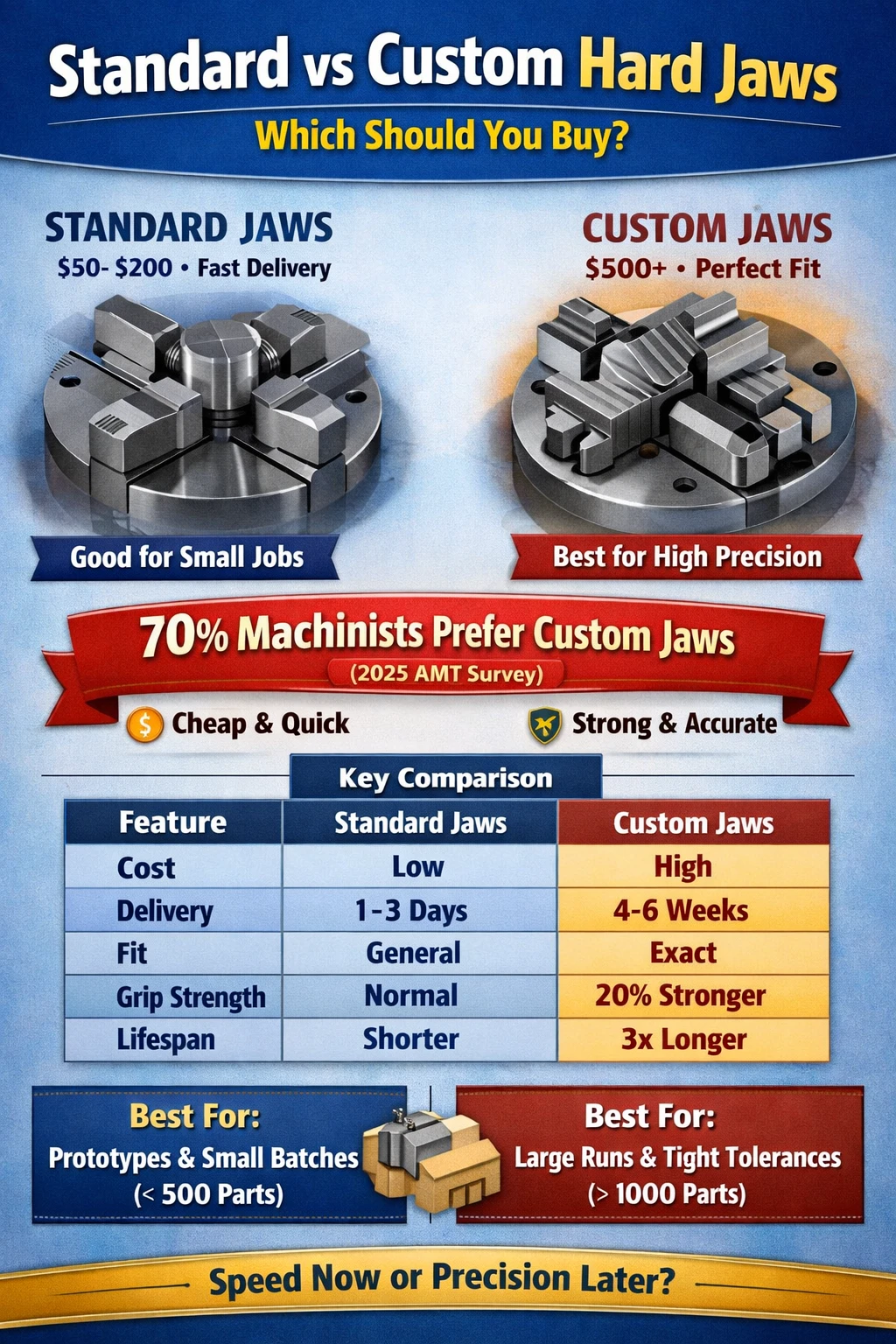

A 2025 AMT survey found that 70% of machinists reported better holding power with custom jaws. But custom jaws cost more and take longer to make.

So what is the right choice?

In this guide, we will compare standard vs custom hard jaws in simple terms. You will learn the pros, cons, costs, and best use cases so you can pick the smartest option for your shop.

What Are Hard Jaws and Why Do They Matter?

Before we compare, let’s first understand what hard jaws are.

Hard jaws are strong steel jaws used in lathe chucks or vises. Their main job is to hold the workpiece tightly while cutting, drilling, or turning.

They are made from tough, heat-treated steel so they can handle high pressure and heavy cutting forces.

If the grip is weak, many problems happen:

-

Parts slip

-

Dimensions go wrong

-

Tools break

-

Scrap increases

-

Machines stop

A good set of jaws can improve your whole process.

Core Functions in Machining

Hard jaws help you:

-

Grip workpieces tight in vises or chucks

-

Hold parts steady during cutting

-

Keep parts aligned and accurate

-

Support heavy loads

Benefits:

-

Reduce slip by up to 90%

-

Improve safety

-

Boost cycle times

-

Reduce scrap

Simply put, better jaws = better machining.

Types Breakdown

There are two main types of hard jaws:

Standard Hard Jaws

These are off-the-shelf jaws.

-

Common sizes

-

Ready to ship

-

Easy to replace

Custom Hard Jaws

These are made specially for your part.

-

Designed to match part shape

-

Built for special sizes

-

Made for precision work

Real Example

Many auto plants use both types.

They use:

-

Standard jaws for general engine parts

-

Custom jaws for special blocks and complex shapes

This mix gives them speed and precision together.

Pros and Cons of Standard Hard Jaws

Let’s start with standard jaws.

Top Advantages

1. Low Cost

Standard jaws are cheaper.

Typical price:

-

$50–$200 per set

Compared to:

-

$500+ for custom jaws

This is great for small shops or tight budgets.

2. Fast Delivery

Most suppliers keep them in stock.

You can get them in:

-

1–3 days

No waiting weeks.

3. Easy Replacement

If a jaw breaks, you simply order another set. No special design needed.

Expert Opinion

“Standards work for 80% of jobs,” says Joe, a machinist with 20 years of experience.

And for many shops, this is true.

Common Drawbacks

But standard jaws are not perfect.

1. Less Grip on Odd Shapes

They are made for general shapes only.

If your part is:

-

Round

-

Square

-

Simple

They work fine.

But for:

-

Thin parts

-

Irregular shapes

-

Complex forms

Grip becomes weak.

Studies show slip risk increases by 25% with poor fit.

2. Faster Wear

In high-volume production, standard jaws wear out faster.

More wear means:

-

More replacements

-

More downtime

-

Higher long-term costs

Action Step

Before using standard jaws:

✔ Always check part fit

✔ Test grip strength

✔ Run a trial piece

This can prevent scrap.

Benefits and Limits of Custom Hard Jaws

Now let’s look at custom jaws.

Key Strengths

1. Perfect Fit

Custom jaws are designed for your exact part.

They:

-

Match the shape

-

Increase surface contact

-

Hold tighter

This means almost zero slip, even on complex parts.

2. Better Precision

Because the part does not move:

You get:

-

Better accuracy

-

Cleaner cuts

-

Fewer rejects

3. Longer Life

Studies show custom jaws can last 3 times more cycles.

So even though they cost more, they last longer.

Case Study

An aerospace company used custom jaws for turbine blades.

Result:

-

Scrap reduced by 40%

-

Setup errors dropped

-

Production speed increased

That’s huge savings.

Expert Quote

“Worth it for repeat jobs,” says tooling expert Lisa Chen.

Potential Downsides

1. Higher Price

Custom jaws cost more upfront.

Typical price:

-

$500–$1,500+

This can feel expensive at first.

2. Longer Lead Time

They are made to order.

Delivery time:

-

4–6 weeks

If you need jaws fast, this is not ideal.

Head-to-Head Comparison

Let’s compare both clearly.

Cost and ROI Breakdown

Standard Jaws

-

Low upfront cost

-

Good for small runs

-

Break even in 1 month

Custom Jaws

-

High upfront cost

-

Best for large runs

-

Payback in 3–6 months

If you make thousands of parts, custom jaws often save money over time.

Quick Comparison Table

| Feature | Standard Hard Jaws | Custom Hard Jaws |

|---|---|---|

| Cost | Low | High |

| Delivery | Fast | Slow |

| Fit | General | Perfect |

| Grip Force | Normal | 20% stronger |

| Setup Time | Faster | Slower |

| Life Span | Shorter | 3x longer |

| Best For | Small jobs | Large production |

Performance Metrics

-

Grip force: Custom = 20% stronger

-

Setup time: Standard = 50% faster

-

Durability: Custom = 3x longer life

Key Takeaway

Match your jaws to your batch size and precision needs.

When to Buy Standard vs Custom

Still unsure? Let’s make it simple.

Ideal Scenarios for Standard Hard Jaws

Choose standard if you:

-

Run prototypes

-

Make small batches (under 500 parts)

-

Change parts often

-

Need fast delivery

-

Have a tight budget

Example

A job shop doing one-off parts daily benefits more from standard jaws. They are quick and cheap.

Best Cases for Custom Hard Jaws

Choose custom if you:

-

Run production over 1,000 pieces

-

Need tight tolerances

-

Work with complex shapes

-

Want less scrap

-

Repeat the same job often

Example

Medical implant or aerospace parts need extreme precision. Custom jaws give better results.

Simple Action List

Before buying, ask:

✔ How many parts will I run?

✔ How tight are my tolerances?

✔ How often do I repeat this job?

✔ Can I wait 4–6 weeks?

✔ What costs more: scrap or custom jaws?

Your answers will guide you.

Conclusion

Both Hard Jaws types have their place.

-

Standard jaws = fast, cheap, flexible

-

Custom jaws = precise, strong, long-lasting

If you need speed and small batches, go standard.

If you need accuracy and large production, go custom.

Many smart shops use both together. In fact, studies show shops mixing both types see a 15% efficiency gain.

So take a moment today.

Audit your current jaws.

Check your scrap rate.

Talk to your supplier for a quote.

Because the right jaw choice can save thousands of dollars.

Ready to upgrade your grip and machine smarter?