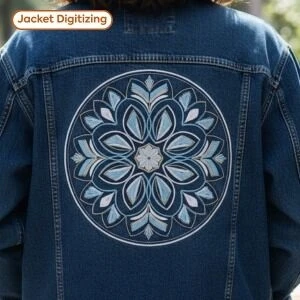

In embroidery, accuracy and detail determine the final quality of a project. One of the more challenging applications is jacket back embroidery. Jackets, especially their back panels, provide a large area for designs, but this also requires careful digitizing, fabric-specific adjustments, and skilled design adaptation. Professional jacket back digitizing helps embroidery businesses and custom apparel providers achieve consistent, high-quality results.

What Is Jacket Back Digitizing?

Jacket back digitizing is the process of converting artwork, logos, or designs into digital embroidery files specifically optimized for the back panel of a jacket. This process addresses challenges not typically found in standard embroidery:

- Large surface area: Back panels are significantly bigger than other apparel areas, requiring designs that scale accurately.

- Fabric differences: Jackets are made from materials such as fleece, leather, nylon, and denim, each requiring unique stitch considerations.

- Movement and tension: Jackets flex and stretch, making proper stitch placement critical for durability and appearance.

A professional digitizer ensures that designs maintain clarity, texture, and longevity across various jacket materials.

Benefits of Professional Jacket Back Digitizing

Relying solely on basic digitizing tools or inexperienced methods can compromise embroidery quality. Professional digitizing offers several advantages:

- Design accuracy: Complex logos and text maintain sharp edges and proper alignment.

- Optimized stitches: Digitizers choose appropriate stitch types (satin, fill, or run) based on design and fabric.

- Fabric protection: Correct stitch density prevents puckering, tearing, and distortion.

- Efficient production: Expert digitizing reduces trial-and-error, saving time and materials.

Key Considerations in Digitizing Jacket Backs

Professional digitizers focus on multiple factors to ensure the final embroidery is precise and durable:

- Placement: Adjusting the design for seams, pockets, and hoods ensures proper alignment on the back panel.

- Stitch direction and flow: Stitches follow the natural grain of the fabric for flexibility and durability.

- Layering and underlay: Underlay stitches stabilize the design and reduce thread breakage.

- Fabric-specific techniques: Heavy fabrics like leather require fewer stitches per inch, while lighter fabrics need careful tension control.

- Software expertise: Advanced digitizing software produces files compatible with industrial embroidery machines.

Applications of Jacket Back Digitizing

Professional digitizing can handle a range of jacket back designs, including:

- Text-based designs: Names, slogans, and identifiers require proper spacing and alignment.

- Logos and emblems: Corporate or club logos need proportional scaling to fit the back panel.

- Illustrations and graphics: Detailed designs demand precise stitch planning and underlay support.

- Combined elements: Text and graphics together require careful layering and spacing for clarity.

Best Practices for Jacket Back Digitizing

Even when working with a professional service, following these steps ensures optimal results:

- Provide high-resolution or vector artwork to minimize loss of detail.

- Specify the jacket material for accurate stitch planning.

- Communicate design dimensions to prevent distortion or resizing issues.

- Discuss thread types and colors to maintain durability and proper coverage.

- Request sample runs to identify adjustments before large-scale production.

Choosing a Professional Digitizing Service

Selecting the right digitizing partner can improve efficiency and quality:

- Experience with outerwear: Not all digitizers specialize in jackets; expertise is essential.

- Portfolio review: Reviewing previous projects demonstrates quality and adaptability.

- Machine compatibility: Ensure the service provides files compatible with your embroidery equipment.

- Revisions and support: A reliable service allows refinements before final production.

FAQs

1. What makes jacket back digitizing different from standard embroidery digitizing?

Jacket back digitizing accounts for larger surfaces, fabric tension, and seam placement, requiring specific stitch density, underlay, and design alignment adjustments.

2. Can any design be digitized for jacket backs?

Most designs can be digitized, but extremely intricate or very large designs may require adjustments to maintain durability and clarity on the jacket material.

3. How do materials affect jacket back embroidery?

Heavy materials like leather or denim require lower stitch density and specialized needles, while lighter fabrics need careful tension management to avoid puckering or distortion.

4. Why is a sample run important before full production?

A test embroidery helps identify placement, size, and stitch density issues early, reducing waste and ensuring the final product meets quality standards.

Conclusion

Professional jacket back digitizing ensures embroidery designs are executed with precision and durability. It bridges the gap between concept and finished product by addressing fabric behavior, stitch optimization, and design placement.

For businesses, teams, or individuals producing custom jackets, investing in professional digitizing leads to consistent, high-quality embroidery that preserves design integrity and enhances the overall garment.