-

1. Introduction to Solid-Liquid Separation

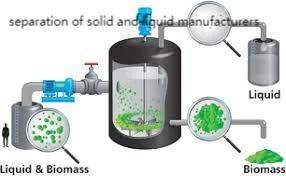

The process of separating solids from liquids is foundational across industries such as wastewater treatment, mining, food processing, and pharmaceuticals. Separation of solid and liquid Manufacturersdesign specialized equipment to achieve this efficiently, ensuring compliance with environmental regulations and operational efficiency. Their innovations address challenges like scalability, energy consumption, and material recovery.

2. Core Technologies in Solid-Liquid Separation

Manufacturers employ diverse technologies, including centrifugation, filtration, and sedimentation. Centrifuges use rotational force to isolate particles, while membrane filtration systems separate materials based on size. Advanced sedimentation tanks leverage gravity for phase separation. These solutions are tailored to handle varying viscosities, particle sizes, and chemical compositions, showcasing the adaptability of separation of solid and liquid manufacturers.

3. Applications Across Industries

In the mining sector, separation systems extract valuable minerals from slurry. Food processors use decanters to clarify juices or recover proteins. Municipalities rely on sludge dewatering equipment to treat wastewater. Each application demands unique configurations, underscoring the importance of manufacturers in delivering customized, high-performance solutions.

4. Sustainability and Environmental Impact

Modern manufacturers prioritize sustainability by developing energy-efficient equipment and closed-loop systems. For instance, filter presses reduce water usage by maximizing liquid recovery, while thermal dryers minimize waste volume. Such innovations help industries meet carbon reduction goals and adhere to circular economy principles.

5. Future Trends and Innovations

Emerging technologies like AI-driven separation systems and nanotechnology-based filters are reshaping the industry. Manufacturers are integrating IoT sensors for real-time monitoring and predictive maintenance. These advancements promise higher precision, lower costs, and faster processing times, reinforcing the critical role of solid-liquid separation experts in a resource-conscious world.

Conclusion

Separation of solid and liquid manufacturers remain indispensable partners for industries seeking efficient, sustainable, and cost-effective solutions. As global demand for cleaner processes grows, their commitment to innovation will continue to drive progress, ensuring safer environments and optimized production cycles.

The Vital Role of Separation of Solid and Liquid Manufacturers in Modern Industry