Tension Controller – Ensuring Precision and Efficiency in Production

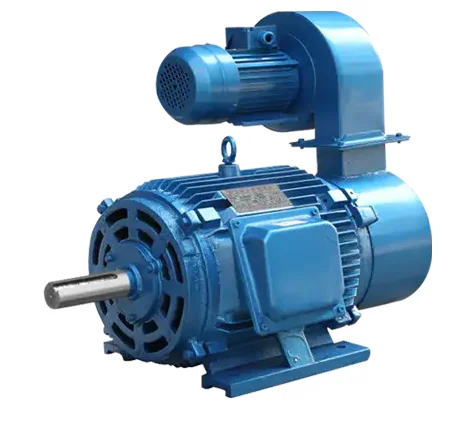

In any manufacturing process, precise control of tension is crucial to achieving high-quality products and maintaining efficient operations. Whether working with textiles, films, wires, or other flexible materials, managing the tension of materials during production can be the difference between success and costly errors. CBB Machine’s Tension Controller offers a reliable and efficient solution for real-time tension monitoring and adjustment, ensuring your production lines remain smooth, consistent, and cost-effective.

The Tension Controller is designed to meet the needs of industries that rely on tension-sensitive materials. This advanced system helps manufacturers improve product quality, reduce waste, and optimize machine performance. By providing accurate tension control, the Tension Controller not only enhances operational efficiency but also contributes to significant cost savings over time.

Key Features and Benefits of the Tension Controller

Real-Time Monitoring and Adjustment

The Tension Controller excels in providing real-time monitoring of material tension throughout the production process. As materials move through various stages of production, the system continuously measures tension levels and adjusts accordingly. This ensures that tension stays within the desired range, preventing common issues like breakage, misalignment, and uneven processing.

Whether you are producing textiles, films, or packaging materials, this system helps eliminate the need for constant manual adjustments, allowing your production lines to operate with minimal downtime and fewer interruptions.

High Precision for Consistent Quality

One of the standout features of the Tension Controller is its ability to deliver highly precise tension control. In many industries, even small fluctuations in tension can result in defects or variations in product quality. With the Tension Controller, manufacturers can avoid problems such as wrinkles, material stretching, or uneven coatings that often occur with improper tension.

By maintaining a constant and accurate tension level, the system ensures that products are manufactured with the highest standards of quality. This is especially important in industries where the visual and functional quality of the finished product is critical, such as textiles, packaging, and printing.

Improved Efficiency and Reduced Downtime

Maintaining consistent tension throughout production not only ensures better quality but also leads to increased operational efficiency. With fewer interruptions caused by tension-related issues, production lines run more smoothly and at a faster pace. The Tension Controller minimizes the need for manual adjustments or troubleshooting, reducing the risk of downtime caused by material-related problems.

As a result, manufacturers experience higher throughput and lower cycle times, which translates to improved productivity and reduced operating costs. This efficiency boost can be particularly valuable in industries with high production demands or tight deadlines.

Versatile and Compatible Across Multiple Applications

The Tension Controller is designed for versatility and compatibility across a wide range of machinery and applications. Whether you're using slitting machines, unwinding units, winding equipment, or printing presses, the Tension Controller can be seamlessly integrated into existing production lines without requiring major modifications.

The system is compatible with various materials, including textiles, films, paper, and metal wires, making it suitable for use in diverse industries. From textile manufacturing and printing to packaging and wire production, the Tension Controller delivers precise tension management, ensuring your production process remains efficient and reliable, regardless of the material or machine in use.

User-Friendly Operation

Despite its advanced features, the Tension Controller is designed to be simple and user-friendly. The digital display provides real-time feedback on tension levels, making it easy for operators to monitor system performance at a glance. With an intuitive interface, operators can make quick adjustments to tension settings without needing extensive technical expertise.

This ease of use reduces the likelihood of errors and ensures that operators can effectively manage the system with minimal training. It also helps streamline the manufacturing process, as operators can quickly address any issues that arise without having to rely on specialists.

Durability and Long-Term Performance

Built for the demands of industrial environments, the Tension Controller is constructed from durable materials designed to withstand continuous operation in harsh conditions. Its robust design ensures long-term reliability and minimal maintenance, making it a dependable addition to any production line.

The system’s durability translates into reduced downtime and fewer disruptions, allowing manufacturers to maintain a high level of productivity over extended periods. By investing in a reliable system, businesses can avoid the costs and hassles associated with frequent repairs and replacements.

Cost Savings Through Waste Reduction

One of the most significant advantages of the Tension Controller is its ability to minimize material waste. Improper tension often leads to defective products, which can result in wasted raw materials and increased scrap. By maintaining optimal tension, the Tension Controller helps ensure that materials are used efficiently, reducing waste and improving overall yield.

In addition to reducing material costs, this waste reduction helps lower costs related to quality control, rework, and the disposal of defective products. Over time, these cost savings can add up, making the Tension Controller a smart investment for manufacturers looking to improve profitability.

Applications Across Various Industries

The Tension Controller is highly adaptable and suitable for a wide variety of industries where tension control is essential. Some key applications include:

Textile Manufacturing: Ensures consistent tension during weaving, knitting, and finishing processes, preventing fabric breakage and ensuring uniformity.

Printing: Maintains optimal tension in printing presses to avoid misprints, smudges, or misalignment of printed materials.

Packaging: Controls tension during the unwinding and rewinding of packaging films and materials, preventing distortion and ensuring smooth operation.

Wire Manufacturing: Regulates tension during wire production to prevent tangling or breakage, ensuring smooth winding and consistent product quality.

Applications in Various Industries

The Tension Controller from CBB Machine is ideal for use in industries that require precise tension control. Some of the key sectors that can benefit from this technology include:https://www. cbbmachine .com/about/

Conclusion

Conclusion

The Tension Controller from CBB Machine is an indispensable tool for manufacturers seeking to improve the precision and efficiency of their production lines. By offering real-time monitoring and automatic adjustment, the system ensures consistent tension control, enhancing product quality and minimizing downtime. Whether you're working in textiles, printing, packaging, or wire manufacturing, the Tension Controller provides an effective solution for optimizing your manufacturing processes, reducing material waste, and boosting productivity. Invest in the Tension Controller to experience the benefits of reliable, efficient, and high-quality production.