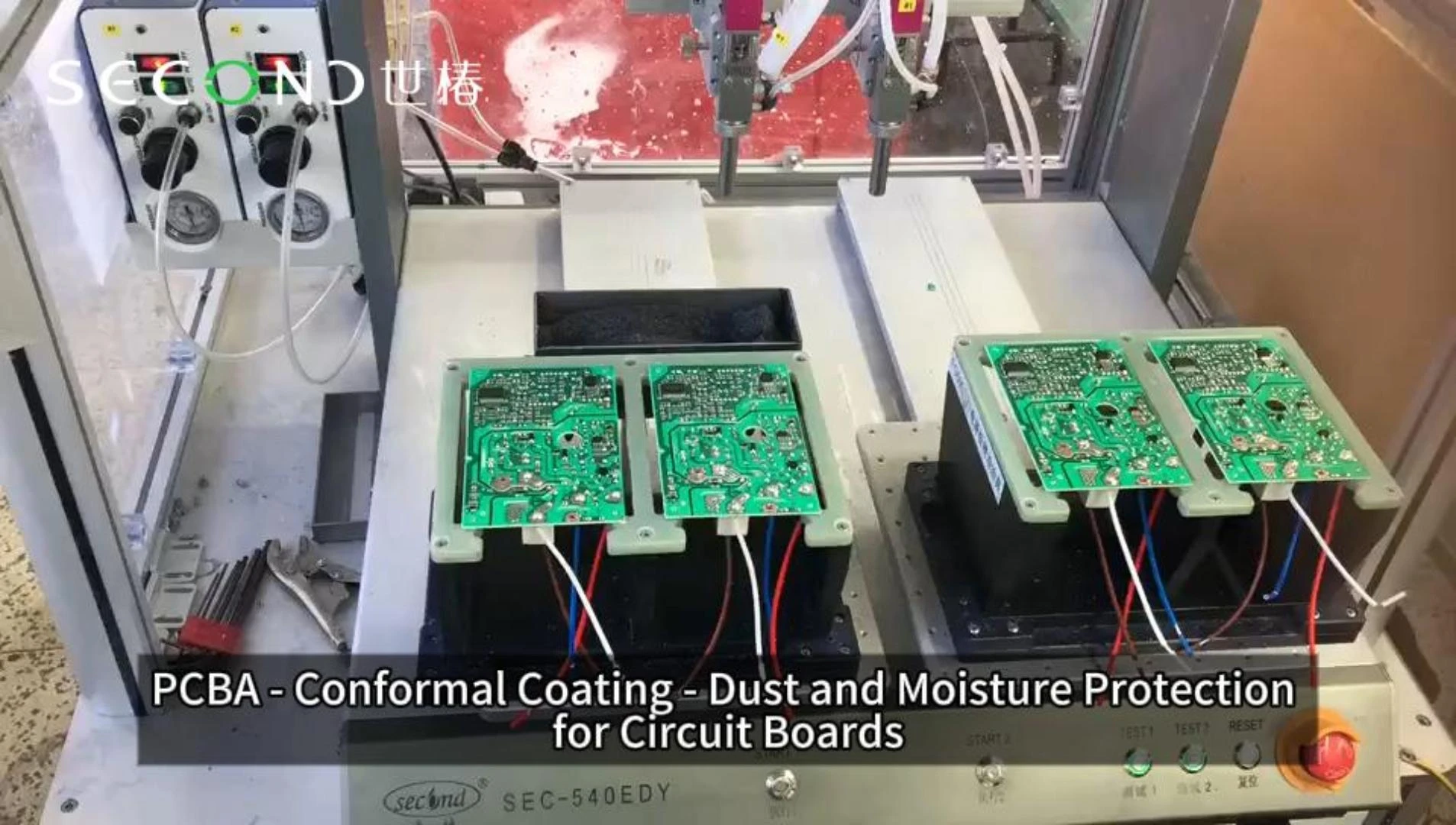

Micro-dispensing application case: How to achieve uniform and precise adhesive coating of sealing resin on connectors?

Achieving uniform and precise adhesive coating of sealing resin on connectors requires high-precision dispensing technology, equipment selection, and process optimization. This, combined with the connector’s structural characteristics and sealing requirements, necessitates breakthroughs in core technologies and system collaboration to achieve precise control of adhesive quantity and consistent coating. The following details the implementation path from four dimensions: technical solutions, core equipment, process optimization, and application effects:

Fully Second Intelligent Equipment Co., Ltd Automatic 3-Axis Potting Machine SEC-S3030B & SEC-S3030C

The work of the glue potting machine mainly depends on air pressure control. Through the air pressure device, the glue is pressed out by pressure, and the size of the glue is controlled by the pump body. At the same time, the robotic arm is responsible for controlling the moving position of the glue discharge to achieve fully automated operation. This automated operation not only solves the problem of low labor efficiency, but also greatly improves the quality of production.

b.High-Efficiency Production: Dispensing speed can reach 5-6 seconds/cycle. The daily output of a single machine is equivalent to 4-6 workers, while reducing inconsistent glue dosage caused by human operation and improving connector sealing yield.

Achieving uniform and precise adhesive coating of sealing resin on connectors requires high-precision dispensing technology, equipment selection, and process optimization. This, combined with the connector’s structural characteristics and sealing requirements, necessitates breakthroughs in core technologies and system collaboration to achieve precise control of adhesive quantity and consistent coating. The following details the implementation path from four dimensions: technical solutions, core equipment, process optimization, and application effects:

Fully Second Intelligent Equipment Co., Ltd Automatic 3-Axis Potting Machine SEC-S3030B & SEC-S3030C

The work of the glue potting machine mainly depends on air pressure control. Through the air pressure device, the glue is pressed out by pressure, and the size of the glue is controlled by the pump body. At the same time, the robotic arm is responsible for controlling the moving position of the glue discharge to achieve fully automated operation. This automated operation not only solves the problem of low labor efficiency, but also greatly improves the quality of production.

b.High-Efficiency Production: Dispensing speed can reach 5-6 seconds/cycle. The daily output of a single machine is equivalent to 4-6 workers, while reducing inconsistent glue dosage caused by human operation and improving connector sealing yield.

Micro-dispensing application case: How to achieve uniform and precise adhesive coating of sealing resin on connectors? Achieving uniform and precise adhesive coating of sealing resin on connectors requires high-precision dispensing technology, equipment selection, and process optimization. This, combined with the connector’s structural characteristics and sealing requirements, necessitates breakthroughs in core technologies and system collaboration to achieve precise control of adhesive quantity and consistent coating. The following details the implementation path from four dimensions: technical solutions, core equipment, process optimization, and application effects: Fully Second Intelligent Equipment Co., Ltd Automatic 3-Axis Potting Machine SEC-S3030B & SEC-S3030C The work of the glue potting machine mainly depends on air pressure control. Through the air pressure device, the glue is pressed out by pressure, and the size of the glue is controlled by the pump body. At the same time, the robotic arm is responsible for controlling the moving position of the glue discharge to achieve fully automated operation. This automated operation not only solves the problem of low labor efficiency, but also greatly improves the quality of production. b.High-Efficiency Production: Dispensing speed can reach 5-6 seconds/cycle. The daily output of a single machine is equivalent to 4-6 workers, while reducing inconsistent glue dosage caused by human operation and improving connector sealing yield.

0 Comments 0 Shares