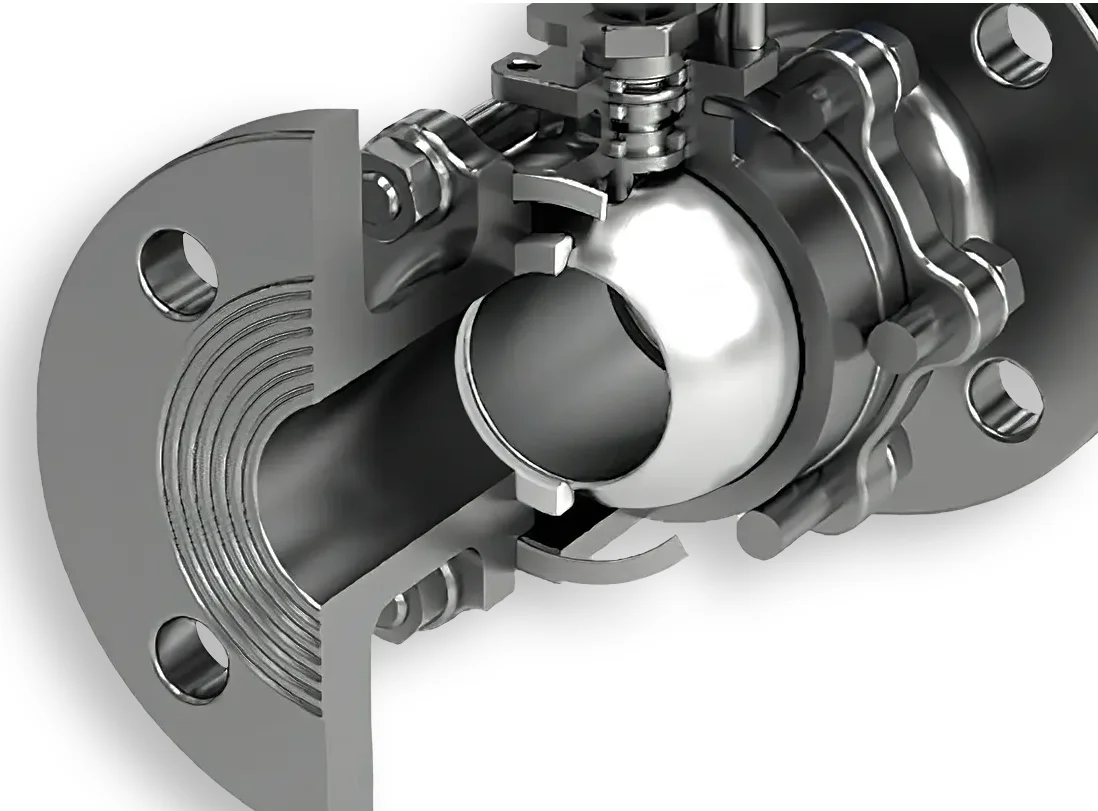

Seal ball valves are widely used components in fluid handling systems, offering effective flow control and sealing performance. The central feature of these valves is a spherical ball that rotates within the valve body to regulate fluid movement. This rotation creates either a passage for flow or a tight seal, depending on the position of the ball.

The construction of seal ball valves emphasizes durability and precision. Valve bodies are typically made from stainless steel, brass, or other corrosion-resistant materials. Seals and seats are carefully selected to ensure minimal leakage and consistent performance over time. The reliable sealing mechanism makes these valves suitable for both high-pressure and low-pressure systems.

In industrial and residential applications, seal ball valves are valued for their ease of operation. They allow for rapid opening and closing, helping operators control flow without extensive manual effort. The valves can also integrate with automated systems, providing remote control capabilities for complex piping networks. Their compact design makes installation practical even in confined spaces.

Maintenance practices for seal ball valves include regular inspection and replacement of worn seals or seats. Attention to material compatibility with the transported fluid prevents corrosion and extends valve lifespan. Proper installation and periodic checks enhance the overall reliability of the system.

Overall, seal ball valves provide consistent and reliable flow control across a wide range of applications. Their design focuses on simplicity, durability, and effective sealing. Understanding their construction and operation allows users to ensure smooth performance and protect the integrity of their fluid systems.