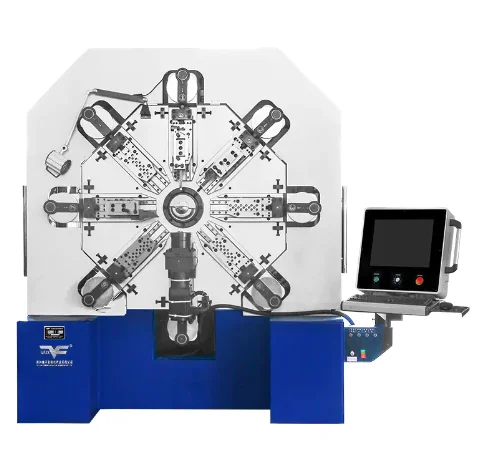

The camless spring machine provides a modern alternative to traditional spring manufacturing equipment. Unlike conventional cam-driven machines, camless systems utilize electronic or hydraulic actuators to control motion, allowing more precise and flexible spring forming. This approach supports a wider variety of spring designs without extensive mechanical adjustments.

In a camless spring machine, the bending angle, feed rate, and stroke can be adjusted digitally. Operators can input parameters for different spring types, and the machine executes the program with high consistency. This flexibility allows for faster changeovers between production runs and reduces the need for specialized tooling. Complex spring geometries, such as variable pitch or double torsion springs, can be created with ease.

The reduction of mechanical parts in camless machines also impacts maintenance positively. Fewer components mean less wear and simpler servicing routines. Digital monitoring tools track machine performance, enabling preventive adjustments and reducing production downtime. Energy efficiency is enhanced as well, since motor output can be matched to actual load conditions, preventing unnecessary power usage.

Camless spring machines are found in diverse manufacturing environments, from small workshops producing custom springs to larger facilities handling continuous production. The combination of programmable control, adaptability, and consistent precision makes these machines suitable for applications where quality and flexibility are essential.

By removing reliance on cam profiles and embracing digital actuation, camless spring machines allow manufacturers to meet evolving spring production demands. The technology supports a streamlined workflow, reduces maintenance complexity, and enables efficient production of a wide range of spring types.