Environmental Challenges in Tape Cutting

Manufacturing environments are rarely perfectly controlled, and factors such as high temperature or humidity can significantly influence production outcomes. For an Elastic Tape Cutting Machine, these conditions affect both the material properties of the tape and the performance of the equipment. Ensuring stable processing in such environments is crucial to maintain product quality, minimize waste, and sustain operational efficiency.

Effects of High Temperature

Elevated temperatures can alter the elasticity and viscosity of tape materials, making them more prone to stretching or deformation during cutting. The machine components themselves may also expand slightly, affecting blade alignment and tension control. Without proper adaptation, high temperatures can result in uneven cuts, inconsistent lengths, and potential damage to the tape. Manufacturers must consider thermal stability in both the tape material and the machine design to ensure consistent performance.

Effects of High Humidity

Humidity introduces moisture into the tape material, which can cause swelling, surface stickiness, or adhesion issues. These changes complicate feeding and cutting, leading to potential jamming or uneven edges. Additionally, high moisture levels can accelerate corrosion of metal parts and affect the lubrication of moving components, further compromising stability. Addressing humidity effects often requires environmental control measures or protective machine coatings to mitigate material and mechanical challenges.

Design and Operational Adjustments

To maintain stable operation under extreme conditions, Elastic Tape Cutting Machines may incorporate design adaptations such as precision-engineered rollers, sealed bearings, and temperature-resistant blades. Adjustable tension control systems allow operators to compensate for material expansion or contraction, while sensors can monitor feed tension and cutting speed in real-time. Operators may also need to adjust environmental parameters, such as introducing dehumidifiers or localized cooling, to ensure the tape retains its intended properties during processing.

Maintenance and Monitoring

Routine maintenance is particularly important when machines operate in challenging environments. Frequent inspection of blades, rollers, and feed mechanisms ensures alignment and lubrication remain optimal. Monitoring material properties and environmental conditions helps operators anticipate deviations and make timely adjustments. Combining proactive maintenance with careful environmental monitoring supports consistent performance, even in high-temperature or high-humidity settings.

Ensuring Consistent Quality in Challenging Conditions

In conclusion, the stability of an Elastic Tape Cutting Machine in high-temperature or humid environments depends on both machine design and operational practices. Understanding the effects of environmental stress on tape properties, implementing adaptive control systems, and maintaining the equipment regularly are essential for consistent quality. By addressing these factors, manufacturers can reliably produce precise cuts while minimizing material waste and operational disruptions.

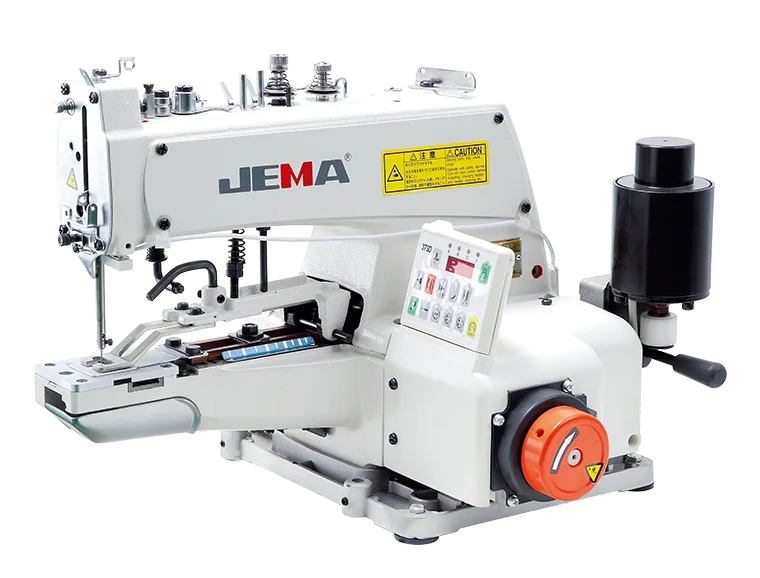

Cutting length (mm): 20-9999

Maximum cutting width (mm): 95

Cutting speed (p/min): 95

Maximum blade temperature( °C ): 350

Voltage (v): 110/220

Frequency (Hz): 50/60

Rated power (kW): 0.64

Packaging size (L × w ×H)(mm ): 560 × 420 × 405

Weight (kg): 19/24

Packing rate (sets): 1