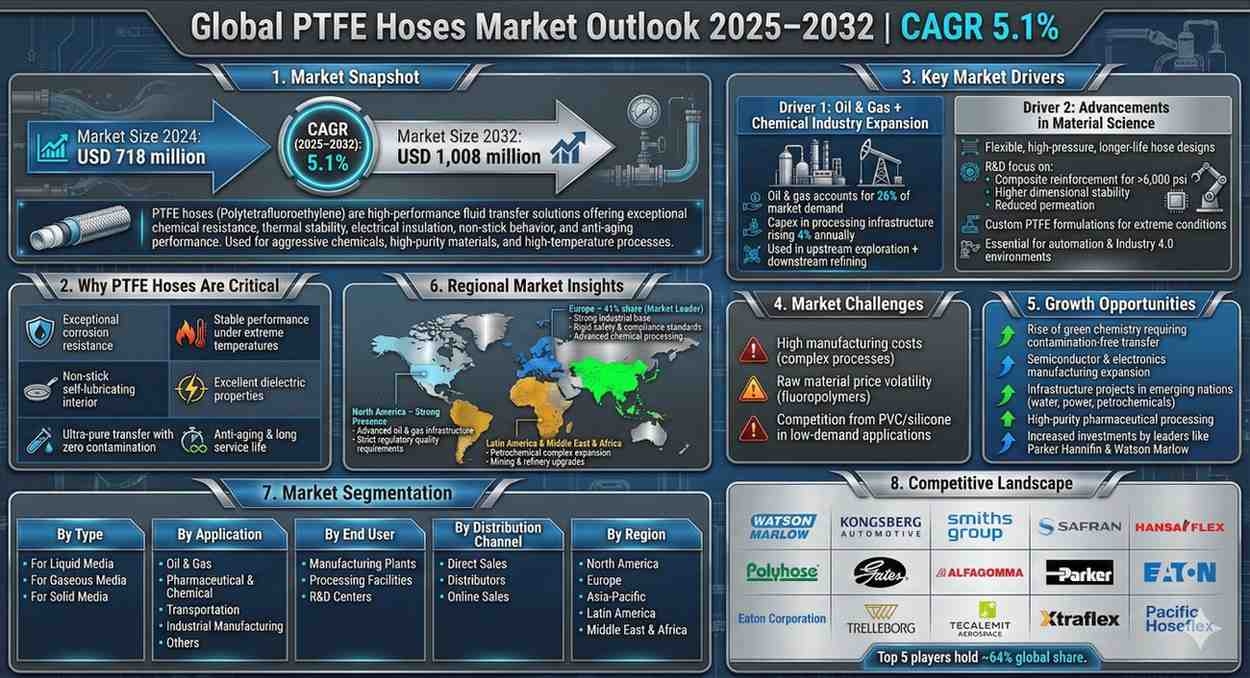

According to a new report from Intel Market Research, the global PTFE Hoses market was valued at USD 718 million in 2024 and is projected to reach USD 1,008 million by 2032, growing at a steady CAGR of 5.1% during the forecast period (2025–2032). This consistent growth is driven by increasing demand from the oil and gas industry, advancements in industrial automation, and the material's unparalleled performance in harsh operating environments.

What are PTFE Hoses?

PTFE hoses, made from Polytetrafluoroethylene, demonstrate exceptional stability, corrosion resistance, self-lubricating non-stick properties, electrical insulation, and excellent anti-aging capabilities. Because of these superior properties, they are predominantly used to transport strong corrosive media at high temperatures, making them indispensable in chemical processing, pharmaceuticals, and energy sectors where safety and reliability are paramount.

Industries rely on these hoses for critical applications because they maintain integrity when handling aggressive acids, solvents, and high-purity materials, thereby preventing contamination and operational failures.

📥 Download FREE Sample Report: PTFE Hoses Market - View in Detailed Research Report

Key Market Drivers

1. Robust Expansion in the Oil and Gas and Chemical Industries

The global demand for energy and chemicals continues to rise, directly fueling the need for reliable fluid transfer systems. The oil and gas sector alone constitutes over 26% of the global PTFE hoses market, with usage increasing in both upstream exploration and downstream refining processes. Recent industry reports highlight that the oil and gas industry's capital expenditure in processing infrastructure is expected to grow at approximately 4% annually, creating substantial opportunities for high-performance hose manufacturers.

2. Advancements in Material Science and Manufacturing Technologies

Manufacturers are continuously innovating to enhance hose performance characteristics, resulting in products with improved flexibility, higher pressure ratings, and longer service life. These innovations are crucial because they enable operations in more extreme conditions, which is why companies are investing heavily in R&D. Furthermore, the push toward Industry 4.0 and automation in manufacturing necessitates components that can withstand harsh operating conditions without failure.

Development activities are increasingly focused on:

- Composite constructions: Integrating reinforcement layers to handle ultra-high pressures exceeding 6,000 psi in specialized applications.

- Enhanced manufacturing precision: Leading to improved dimensional stability and reduced permeation rates.

- Customized formulations: Tailoring PTFE properties for specific chemical resistance or temperature requirements.

- These technological strides are positioning PTFE hoses as critical enablers of next-generation industrial processes.

- Market Challenges

- High manufacturing costs: The complex production process and premium raw materials result in higher costs compared to alternative hose types, which can limit adoption in price-sensitive markets.

- Raw material price volatility: Fluctuations in fluoropolymer prices directly impact production costs and profit margins for manufacturers.

- Competition from alternative materials: In less demanding applications, manufacturers may opt for lower-cost hoses made from materials like PVC or silicone, thereby restraining market growth in certain segments.

- Opportunities Ahead

- The global transition toward sustainable manufacturing and stricter environmental regulations present a favorable outlook for PTFE adoption. Regions such as Asia-Pacific, Latin America, and Middle East & Africa are witnessing accelerating demand through:

- Green chemistry initiatives: Driving demand for contamination-free fluid transfer.

- Expansion of semiconductor and electronics manufacturing: Where ultra-pure fluid handling is critical.

- Infrastructure development in emerging economies: Creating new applications in water treatment and power generation.

- Leading players like Watson Marlow and Parker Hannifin are capitalizing on these trends through expanded production capacities and strategic acquisitions.

- Regional Market Insights

- Europe: Dominates the global market with approximately 41% share, supported by a strong industrial base, stringent safety standards, and technological leadership in chemical processing equipment.

- Asia-Pacific: Shows the fastest growth potential due to rapid industrialization, foreign investments in manufacturing, and increasing energy demands.

- North America: Maintains a significant market presence due to its advanced oil and gas sector and stringent industry regulations mandating high-performance components.

- Latin America and Middle East & Africa: Are emerging as important growth regions with investments in petrochemical complexes and mining operations driving PTFE hose consumption.

- Market Segmentation

- By Type

- For Liquid Media

- For Gaseous Media

- For Solid Media

By Application

- Oil and Gas

- Pharmaceutical and Chemical

- Transportation

- Industrial Manufacturing

- Others

By End User

- Manufacturing Plants

- Processing Facilities

- Research & Development Centers

By Distribution Channel

- Direct Sales

- Distributors

- Online Sales

By Region

- North America

- Europe

- Asia-Pacific

- Latin America

- Middle East & Africa

📘 Get Full Report Here: PTFE Hoses Market - View in Detailed Research Report

Competitive Landscape

The global PTFE hoses market is characterized by the presence of established multinational corporations and specialized manufacturers. While the market remains consolidated, with the top five players holding approximately 64% market share, competition is intensifying as companies expand their global footprint and product portfolios.

The report provides in-depth competitive profiling of key players, including:

- Watson Marlow

- Kongsberg Automotive

- Smiths Group

- Safran

- HANSA-FLEX

- Polyhose

- Gates

- Alfagomma

- Parker Hannifin

- Eaton Corporation

- Trelleborg

- Tecalemit Aerospace

- Xtraflex

- Pacific Hoseflex

Report Deliverables

- Global and regional market forecasts from 2025 to 2032

- Strategic insights into technological developments and regulatory compliance

- Market share analysis and competitive benchmarking

- Pricing trend analysis and supply chain assessment

- Comprehensive segmentation by type, application, end user, and geography

📥 Download FREE Sample Report: PTFE Hoses Market - View in Detailed Research Report

About Intel Market Research

Intel Market Research is a leading provider of strategic intelligence, offering actionable insights in biotechnology, pharmaceuticals, and healthcare infrastructure. Our research capabilities include:

- Real-time competitive benchmarking

- Global clinical trial pipeline monitoring

- Country-specific regulatory and pricing analysis

- Over 500+ healthcare reports annually

Trusted by Fortune 500 companies, our insights empower decision-makers to drive innovation with confidence.

🌐 Website: https://www.intelmarketresearch.com

📞 International: +1 (332) 2424 294

📞 Asia-Pacific: +91 9169164321

🔗 LinkedIn: Follow Us