3D Printing Powder Market Trends & Summary

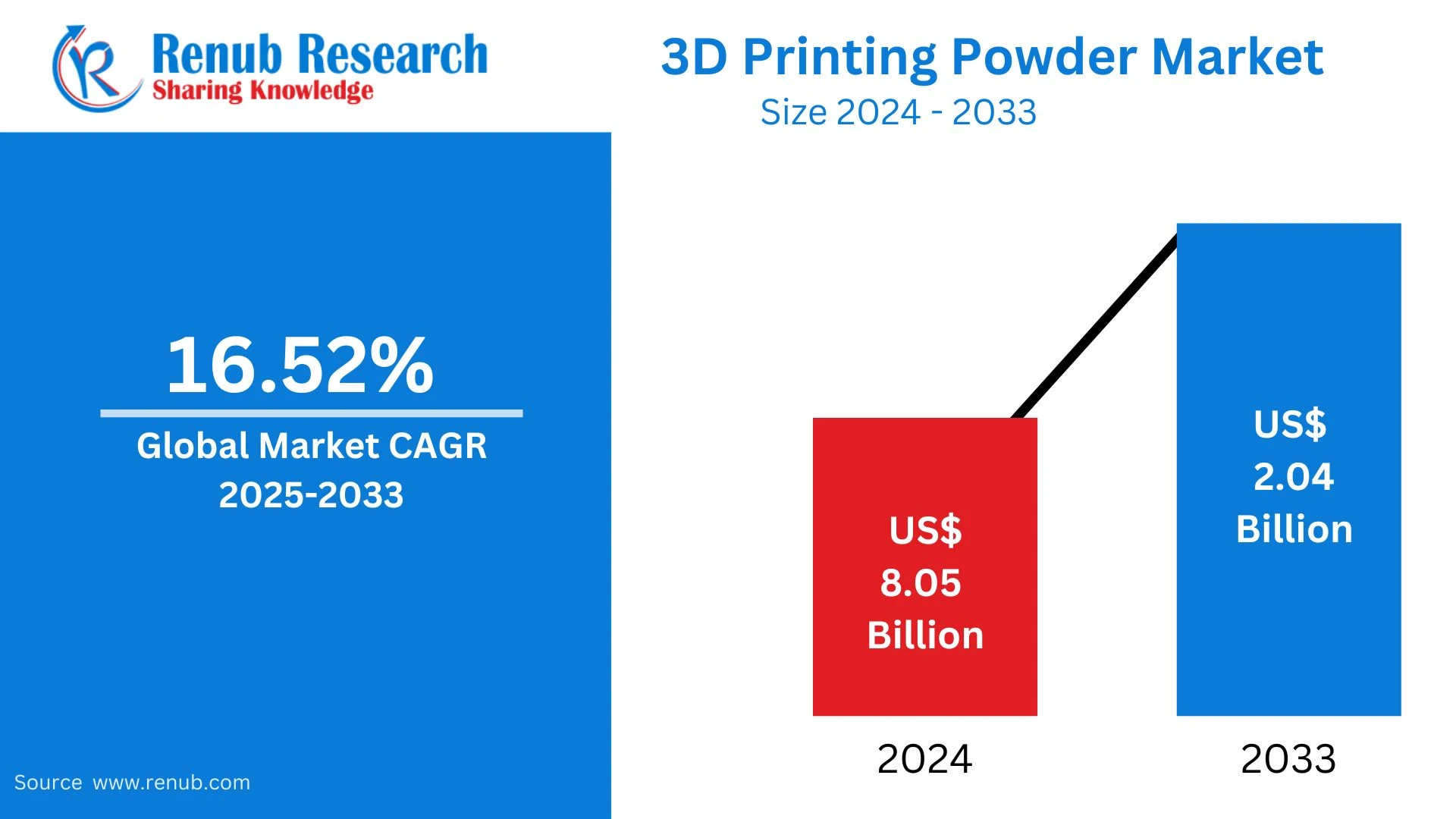

According to Renub Research global 3D Printing Powder Market is experiencing remarkable growth as industries worldwide shift toward advanced manufacturing technologies and customized production solutions. The market value is expected to soar from US$ 2.04 billion in 2024 to US$ 8.05 billion by 2033, registering a robust CAGR of 16.52% during 2025–2033. This exponential expansion is fueled by technological advancements, wider adoption of additive manufacturing, and rising demand for high-performance customized components across several sectors including automotive, aerospace, healthcare, defense, architecture, and industrial manufacturing.

The increasing adoption of Select Laser Sintering (SLS), Direct Metal Laser Sintering (DMLS), and Electron Beam Melting (EBM) has significantly enhanced the efficiency and capability of 3D printing powders. These powders, available in metal, plastic, ceramic, and glass forms, enable industries to manufacture lightweight, precise, durable, and complex products with minimal waste.

Download Free Sample Report:https://www.renub.com/request-sample-page.php?gturl=3d-printing-powder-market-p.php

Market Outlook: Understanding 3D Printing Powder

3D printing powder serves as the core material for additive manufacturing processes, helping transform digital models into physical objects by building them layer-by-layer. These powders are carefully designed to deliver consistency, strength, thermal stability, and smooth processing performance.

Industries use different powder types depending on application needs:

- Metal powders for aerospace, automotive, defense, and medical implants

- Plastic powders for consumer goods, industrial parts, prototyping, and education

- Ceramic and glass powders for high-precision engineering, electronics, and art

- Composite powders for specialized high-performance components

With increasing emphasis on lightweight materials, precision manufacturing, and sustainable production, the demand for 3D printing powders continues to rise sharply.

Key Growth Drivers in the Global 3D Printing Powder Market

Technological Advancements Transforming Production

One of the biggest catalysts for market growth is the rapid improvement in 3D printing technologies. Innovations like advanced laser sintering systems, enhanced material compatibility, and automated manufacturing setups are increasing production accuracy while reducing operational costs.

Modern printers enable industries to develop intricate geometries, achieve tight tolerances, and produce durable, high-strength components. For instance, in January 2024, Revo Foods introduced the world’s first industrial food 3D printer, highlighting how versatile the technology has become.

As industries continue to integrate next-generation 3D printing solutions, the need for high-grade printing powders will surge significantly.

Surge in Demand for Custom Manufacturing

Customization is redefining modern manufacturing. Today’s industries demand tailor-made components, whether it is an aerospace engine part, a lightweight automotive design, or a personalized medical implant.

3D printing powders enable rapid production of complex, bespoke products that traditional manufacturing cannot easily achieve. The healthcare sector is witnessing substantial benefits, particularly in custom prosthetics and implants. Similarly, aerospace companies are adopting additive manufacturing to develop lightweight aircraft parts, improving fuel efficiency and performance.

The launch of Create It REAL’s digital orthopedic ordering platform in 2024 further strengthens the adoption of customized manufacturing solutions.

Cost Efficiency and Environmental Sustainability

Sustainability is a major concern for modern industries, and 3D printing excels in material efficiency. Unlike conventional subtractive manufacturing, additive manufacturing uses only the required material, significantly reducing waste.

The technology contributes to:

- Lower raw material usage

- Reduced energy consumption

- Faster production cycles

- Reduced carbon footprint

In July 2023, 14Trees introduced Africa’s first commercial 3D construction printer, enabling cost-effective and eco-friendly building practices. Such innovations enhance the appeal of 3D printing powders worldwide.

Key Market Challenges

High Cost of Advanced Powders

Despite strong potential, the market faces cost-related challenges. Premium materials, especially metal powders, remain expensive due to complex production processes. This is a hurdle for smaller companies and startups looking to adopt advanced manufacturing technologies.

Quality Consistency and Standardization Issues

Maintaining uniform quality across powder batches can be challenging. Variations in particle size, distribution, and composition may impact final product performance. Industries like aerospace and healthcare require strict precision and reliability, making standardization essential.

Market Insights by Material Type

Global 3D Printing Plastic Powder Market

Plastic powders such as Nylon, PLA, and Polystyrene dominate due to their:

- Lightweight characteristics

- Cost efficiency

- High flexibility

- Ease of processing

They are widely utilized in automotive, consumer products, electronics, and education, particularly for prototyping and functional part creation.

Global 3D Printing Metal Powder Market

Metal powders including Titanium, Aluminum, and Stainless Steel are rapidly gaining momentum. These powders support the development of high-strength, heat-resistant, and lightweight components essential in aerospace, defense, automotive, and medical implants.

Ongoing research in advanced metal alloys and improved printing techniques will continue to fuel market growth.

Major Industry Applications

Automotive Industry Adoption

The automotive industry is one of the largest adopters of 3D printing powders. Manufacturers use metal and plastic powders for:

- Lightweight components

- Custom design elements

- Rapid prototyping

- Electric vehicle innovations

3D printing supports sustainability targets by minimizing waste and reducing energy consumption during production.

Healthcare and Medical Advancements

The medical industry benefits greatly through precision healthcare solutions. 3D printing powders help produce:

- Customized implants

- Prosthetics

- Surgical tools

- Tissue engineering structures

Increasing demand for patient-specific treatments ensures continued market expansion.

Regional Market Analysis

United States: A Global Leader

The U.S. dominates the global market due to its strong manufacturing ecosystem, technological infrastructure, and investment initiatives. Aerospace, healthcare, and automotive industries heavily rely on additive manufacturing technologies.

In January 2024, KBM Advanced Materials partnered with Sandvik to distribute Osprey metal powders across the U.S., strengthening domestic supply capabilities.

Germany: Europe’s Additive Manufacturing Powerhouse

Germany stands as a global leader in precision engineering and industrial innovation. The country heavily adopts 3D printing across aerospace, automotive, and industrial manufacturing.

Companies such as Evonik continuously innovate new powder formulations, including flame-retardant materials and high-performance polymers, strengthening the market.

India: Emerging Market with Strong Potential

India’s 3D printing powder market is flourishing under government initiatives like Make in India, increasing manufacturing activity, and tech adoption. Industries including automotive, education, and consumer goods are utilizing 3D printing for prototyping and production efficiency.

The launch of India’s first SLS 3D printer in January 2024 further highlights the country’s growing technological strength.

Saudi Arabia: Transforming Through Vision 2030

Saudi Arabia is rapidly investing in futuristic technologies to diversify its economy. Adoption of 3D printing in construction, aerospace, oil & gas, and manufacturing supports local innovation and reduces import dependence.

In January 2025, a major partnership between Roboze and SLB was signed to locally produce non-metallic 3D printed components, strengthening the nation’s production ecosystem.

Market Segmentation

By Powder Type

- Plastic Powder

- Metal Powder

- Ceramic Powder

- Glass Powder

- Others

By End User

- Industry

- Automotive

- Aerospace & Defense

- Medical

- Architecture

By Region

- North America

- Europe

- Asia Pacific

- Latin America

- Middle East & Africa

Key Market Players

Leading companies shaping the global market include:

- Arkema

- BASF SE

- Evonik Industries AG

- ExOne

- General Electric

- Höganäs AB

- Sandvik AB

- Metalysis

These companies focus on innovation, strategic partnerships, capacity expansion, and advanced material development to strengthen their competitive position.

Conclusion: Future Outlook of the 3D Printing Powder Market

The 3D Printing Powder Market is set for dynamic growth driven by rising adoption of additive manufacturing, technological breakthroughs, sustainability initiatives, and increasing demand for customization. As industries worldwide continue to prioritize efficiency, precision, and innovation, 3D printing powders will become indispensable in advanced manufacturing ecosystems.

With strong opportunities in automotive, aerospace, healthcare, industrial production, and construction, the market promises remarkable expansion toward 2033 and beyond.