Vehicles manufactured with dual propulsion technology have gained widespread popularity among drivers seeking fuel efficiency and environmental responsibility. These automobiles depend on sophisticated energy storage systems that power electric motors while working in harmony with traditional combustion engines. Over years of operation, the high-voltage components that enable electric driving can experience diminished capacity that affects overall vehicle performance. Warning indicators, reduced fuel economy, and changes in driving dynamics often signal that attention is needed to restore optimal function.

Facing power system challenges can feel overwhelming for vehicle owners who worry about potential expenses and uncertain solutions. Traditional approaches often emphasize complete system replacement as the primary option, leading many drivers to believe they must choose between significant financial investment or accepting degraded performance. Recent advances in diagnostic technology and repair methodologies have created alternative pathways that address specific component failures while preserving elements that remain functional. Learning about these options empowers owners to make decisions that extend vehicle life without unnecessary expense.

Identifying Declining Energy Storage Performance

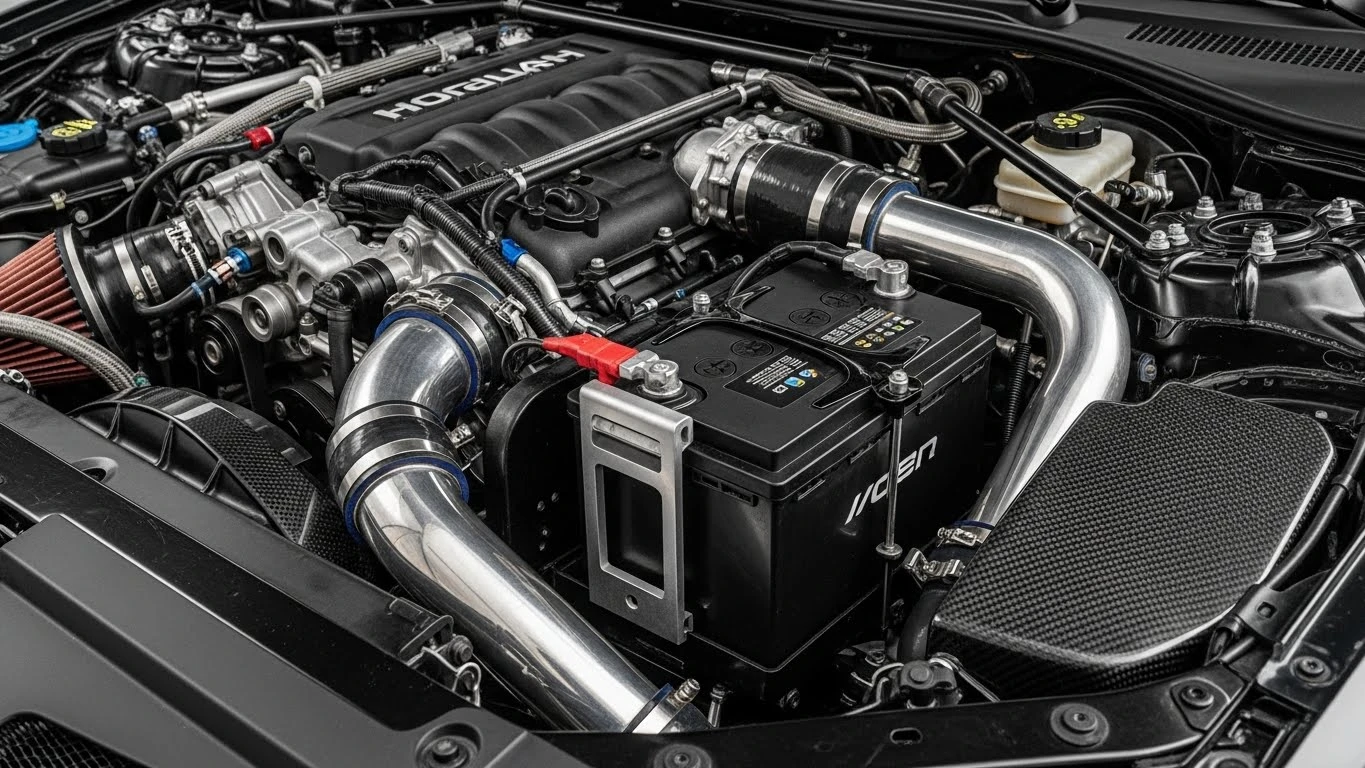

High-voltage power packs contain multiple individual cells arranged in series and parallel configurations to deliver the voltage and current required for electric propulsion. Each cell must maintain consistent capacity and internal resistance for the entire system to operate efficiently. When certain cells begin losing their ability to store and deliver energy, the vehicle's monitoring system detects these imbalances and implements protective limitations. Drivers experience these safeguards as reduced electric range, increased reliance on the gasoline engine, or diminished acceleration response.

Environmental factors including temperature extremes and humidity affect how quickly cells degrade over time. Parking habits, charging patterns, and typical driving distances all influence the rate of capacity loss within individual cells. Manufacturing variations mean that some cells naturally wear faster than others even under identical operating conditions. These differences accumulate over thousands of miles, creating situations where a relatively small number of problematic cells compromise the performance of an otherwise healthy system.

Specialized Approaches for Japanese Automotive Technology

Vehicles from Japanese manufacturers employ specific battery management systems and cell configurations that require specialized knowledge for effective diagnosis and restoration. Understanding the unique characteristics of these systems allows technicians to develop targeted strategies that address failures while maintaining compatibility with the vehicle's existing electronics. Proper diagnostic equipment calibrated for these specific vehicles provides accurate measurements that guide restoration decisions.

Owners seeking solutions for their Japanese eco-vehicles benefit from services that understand the particular requirements of these systems. Experienced professionals recognize the differences in cell chemistry, pack configuration, and management algorithms that distinguish various models and production years. This specialized expertise ensures that Honda hybrid battery repair addresses not just the symptoms but the underlying causes of performance degradation. Techniques including individual cell replacement, capacity balancing, and thermal management optimization restore functionality while preserving the sophisticated integration between electric and gasoline propulsion systems. These targeted interventions allow vehicles to return to the efficiency levels that made them attractive purchases originally.

Diagnostic Excellence Through Advanced Testing

Comprehensive evaluation begins with connecting sophisticated diagnostic equipment that interfaces directly with the vehicle's battery management computer. This connection provides access to detailed operational data including cell voltages, temperature readings, and historical performance metrics stored in the system's memory. Analyzing this information reveals patterns of degradation and identifies which specific modules have fallen outside acceptable parameters.

Following computer diagnostics, technicians perform hands-on testing of individual modules using specialized load testing equipment. This process measures actual capacity under simulated driving conditions rather than relying solely on static voltage measurements. Load testing reveals problems that might not appear during simple meter readings, providing a more complete picture of system health. Thermal imaging may also identify cells generating excessive heat during operation, indicating internal damage or deterioration that requires attention.

Economic Wisdom in Power System Maintenance

Financial considerations naturally influence how owners approach power system problems. Dealership quotes for complete pack replacement often exceed five thousand dollars, representing a substantial portion of many vehicles' current value. This expense creates difficult situations for owners of mechanically sound automobiles that could provide years of additional service if the energy storage system were restored to proper function.

Alternative restoration approaches that focus on replacing only failed components while retaining healthy elements typically reduce costs by half or more compared to complete replacement. This significant savings makes continued vehicle ownership financially sensible rather than forcing owners toward premature trade-ins or purchases. The extended service life achieved through proper restoration amplifies these savings, allowing drivers to enjoy years of efficient operation without the depreciation costs associated with newer vehicles.

Environmental Stewardship Through Component Longevity

Selecting repair over replacement demonstrates commitment to environmental responsibility that extends beyond simply driving a fuel-efficient vehicle. Manufacturing new power packs requires intensive industrial processes that consume significant energy and generate substantial emissions. Raw material extraction for lithium, cobalt, and nickel involves mining operations with considerable ecological impact. Choosing to extend the life of existing components reduces demand for new production and lessens the environmental burden of vehicle ownership.

Responsible recycling practices ensure that components reaching true end of life return valuable materials to the manufacturing supply chain. Certified recycling facilities process these materials according to strict environmental standards, recovering elements for use in future production. This circular economy approach maximizes resource efficiency while minimizing waste. Owners who prioritize repair contribute to more sustainable patterns of consumption and resource management.

Practical Considerations for Vehicle Owners

Multiple factors influence which service approach best fits individual circumstances. Vehicle age provides important context for decision making, as newer automobiles with substantial remaining value justify more comprehensive restoration investments. Overall mechanical condition matters as well, since power system restoration makes most sense when other major components including transmission, suspension, and engine remain healthy and capable of continued service.

Personal financial situations and future plans also guide appropriate choices. Owners planning extended vehicle retention gain maximum benefit from thorough restoration that optimizes longevity and performance. Those considering replacement within several years might prefer focused interventions that address immediate concerns without extensive investment. Honest professional assessment helps clarify realistic expectations and ensures decisions align with individual goals and circumstances.

Maintaining Long-Term System Health

Following restoration, certain practices help maximize the renewed system's service life. Avoiding extreme temperature exposure when possible reduces stress on cells and slows degradation processes. Regular driving that allows full charge and discharge cycles maintains cell balance and prevents capacity loss from disuse. Monitoring dashboard indicators and addressing warning lights promptly prevents minor issues from developing into major problems requiring extensive intervention.

Periodic professional evaluation can identify emerging problems before they significantly impact performance. Annual or biannual diagnostic checks provide insight into how the system is aging and whether preventive measures might extend service life. This proactive approach often proves more economical than waiting for complete failure to occur.

Conclusion

Energy storage systems in vehicles combining electric and gasoline propulsion represent sophisticated technology that requires occasional professional attention. Understanding available options when performance issues emerge helps owners make informed decisions balancing cost, performance, and longevity. Modern repair methodologies offer targeted solutions that address specific component failures while preserving functional elements, extending system life without the expense of complete replacement. Through proper diagnosis and appropriate intervention, these vehicles continue delivering the efficiency and reduced environmental impact that make them valuable long-term transportation choices. Owners who invest wisely in maintaining their power systems enjoy extended service life, continued fuel economy benefits, and the satisfaction of making environmentally responsible choices that maximize value throughout their ownership experience.