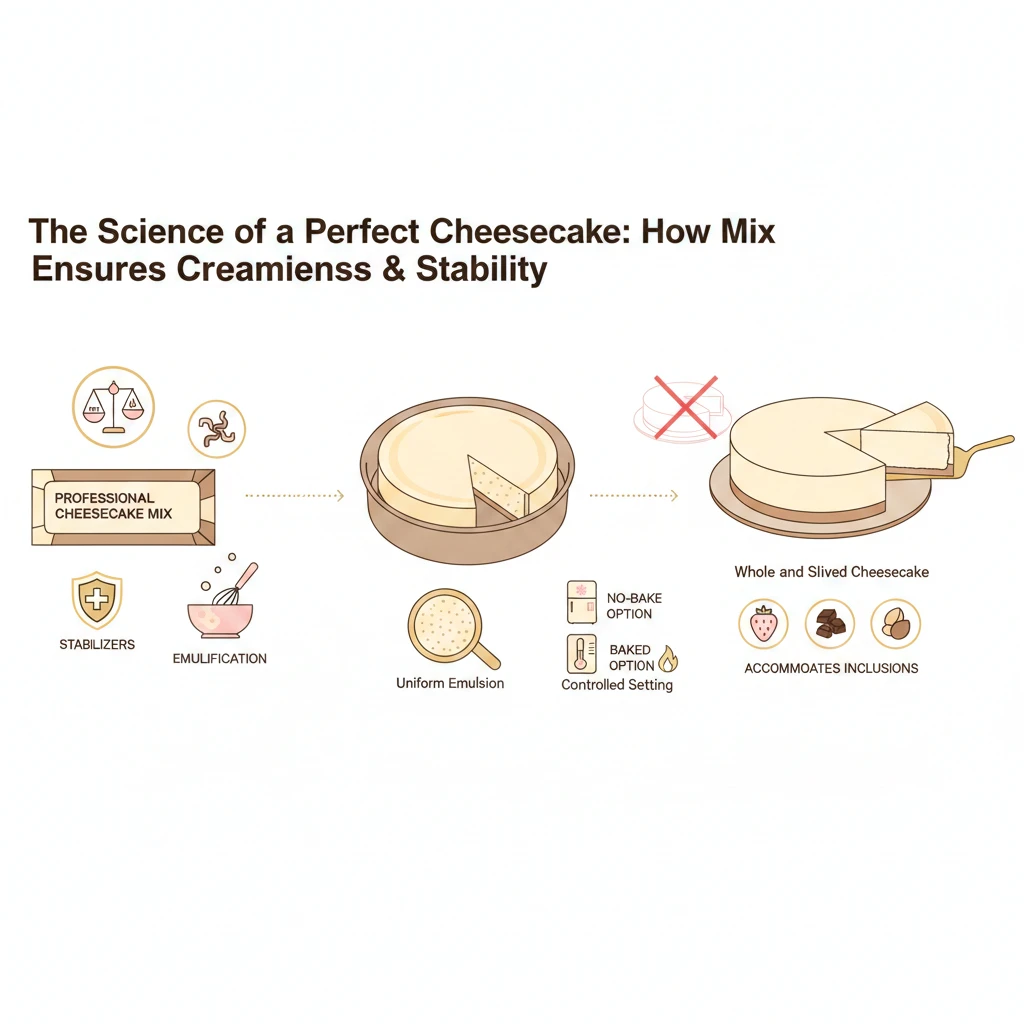

A professional cheesecake mix is specifically designed to maintain both creaminess and structural stability during every stage of production, from mixing and baking to cooling and storage. For commercial bakeries, this ensures that every batch has a smooth, rich mouthfeel, minimal cracking, and consistent texture. The mix achieves this by balancing fats, proteins, and stabilizers to create a uniform emulsion, retain moisture, and maintain shape. This reduces reliance on manual adjustments, which is critical when producing large quantities or supplying multiple locations.

Fat and Protein Balance

Creaminess in cheesecakes relies on a precise balance of fats and proteins. Fats, sourced from cream cheese, butter, or heavy cream, deliver richness, while proteins provide structure and support to hold the cheesecake together.

In high-volume operations, scaling recipes or adding inclusions such as chocolate, fruits, or nuts can upset this balance, potentially resulting in curdled batter, uneven texture, or shrinkage. A professionally formulated mix ensures:

• Standardized fat-to-protein ratios for consistent texture

• Emulsification that prevents separation during mixing

• Reduced dependency on operator experience for consistent outcomes

This predictability is particularly important in commercial bakeries, where even minor deviations can lead to visible differences across batches.

Stabilizers for Structural Integrity

Structural stability is maintained through stabilizers like gelatin, pectin, or modified starches. These ingredients:

• Reinforce the cheesecake matrix, reducing cracking

• Retain moisture to maintain a tender, creamy texture

• Support shape retention during slicing, transport, and display

For bakeries, these stabilizers are essential. They help reduce waste, maintain visual appeal, and ensure consistent portions, which is critical for catering, retail, or wholesale operations.

Mixing Techniques

Even with a reliable cheesecake mix, proper mixing technique significantly affects the final outcome. Mixing ensures ingredients are evenly incorporated while controlling aeration. Over-mixing can introduce too much air, causing cracks, while under-mixing can result in uneven texture.

Professional bakers follow these best practices:

• Mix at moderate speed to create a smooth, lump-free batter

• Keep dairy ingredients at consistent temperatures to prevent separation

• Incorporate air carefully to maintain lightness without compromising structure

A high-quality cheesecake mix allows for some operator variability, providing consistent results even across multiple shifts or staff members.

Setting and Chilling Performance

For no-bake cheesecakes, the setting phase replaces baking as the most critical stage for texture and stability. A professionally formulated no-bake cheesecake mix is designed to set consistently under refrigeration without heat:

-

Controlled setting prevents slumping or soft centers

-

Stabilizers help the cheesecake firm evenly without becoming rubbery

-

Balanced fat and moisture levels support a smooth, creamy finish

For bakeries preparing multiple units simultaneously, predictable setting behavior simplifies production timelines, supports uniform results across batches, and ensures cheesecakes are ready for slicing, display, or transport without structural issues.

Cooling and Storage

Proper cooling is essential to maintain both creaminess and structural integrity. A professional mix ensures predictable behavior during this stage:

• Gradual cooling minimizes contraction and cracking

• Stabilizers retain moisture for smooth, tender crumb

• Shape retention allows cheesecakes to be ready for slicing, display, and transport

Consistent cooling procedures also help commercial operations reduce waste and maintain product quality during storage or distribution.

Accommodating Inclusions

Bakeries frequently incorporate fruits, chocolate, nuts, or other flavors. A professional cheesecake mix is formulated to handle these additions without compromising structure or texture:

• Maintains water balance, even with high-moisture ingredients

• Prevents sinkholes or uneven distribution around heavier inclusions

• Retains smooth, creamy texture

This flexibility allows bakeries to offer seasonal or specialty flavors while keeping product quality uniform across all batches.

Portioning and Presentation

Structural stability directly impacts portioning and presentation. A reliable cheesecake mix allows bakeries to:

• Produce clean, uniform slices for retail, catering, or plated service

• Reduce crumbling and spillage during handling

• Maintain visual appeal across large-scale production

For professional operations, this means efficient service, reduced waste, and consistent presentation standards.

Operational Benefits

Using a standardized mix reduces reliance on operator skill and improves overall operational efficiency:

• Produces consistent results across different shifts and teams

• Lowers training requirements for new staff

• Minimizes errors and waste in high-volume production

• Supports brand standards with uniform texture and flavor

Predictable behavior allows bakeries to scale operations efficiently without compromising quality, making it ideal for wholesale or multi-location setups.

Flavor Profile and Mouthfeel

In addition to structure, the mix ensures consistent flavor and mouthfeel:

• Balanced fats and proteins create a smooth, creamy taste

• Stabilizers prevent dry or grainy textures during storage

• Uniform creaminess enhances the overall eating experience

Maintaining both flavor and texture consistency is especially important for bakeries producing a range of flavors or specialty items for retail and wholesale distribution.

Flexibility for Recipe Development

Professional bakers often need to create variations such as flavored bases, layered cheesecakes, or individual portions. A well-formulated mix allows:

• Flavors and inclusions to be added without compromising structure

• Baking and cooling behavior to remain predictable

• Creaminess and stability to be maintained across different formats

This versatility supports menu innovation, seasonal offerings, and smaller portion sizes without affecting operational efficiency or product quality.

Shelf Life and Transport Considerations

A professional cheesecake mix is also engineered to maintain quality during storage and transport. Stabilizers and balanced moisture content:

• Help preserve creaminess during refrigeration or short-term freezing

• Maintain structural integrity during transport

• Reduce risk of condensation or shrinkage that can affect product appearance

These properties are essential for bakeries supplying multiple locations or delivering large orders for events and catering.

Conclusion

A professional cheesecake mix is essential for bakeries seeking consistent creaminess and structural stability. By balancing fats, proteins, and stabilizers, the mix delivers predictable texture, minimizes cracking, and supports uniform, clean slices. It accommodates inclusions, reduces reliance on operator skill, and maintains quality during cooling, and transport. For commercial bakeries, this translates to operational efficiency, reduced waste, and reliable product quality that meets professional standards.

FAQs

Can hydration be adjusted with a cheesecake mix?

Minor adjustments are possible, but the mix is formulated to maintain creaminess without significant changes.

How does the mix prevent cracking?

Stabilizers reinforce the structure, reduce shrinkage during baking, and maintain moisture balance.

Is it suitable for flavored or filled cheesecakes?

Yes, fruits, chocolate, or nuts can be incorporated without affecting texture or stability.

Can cheesecakes made with the mix be frozen?

Yes, properly baked and cooled cheesecakes freeze well, retaining texture and structure.

Does the mix impact slicing quality?

Yes, it supports stable structure, allowing clean and uniform slices.

Why is a cheesecake mix important in commercial production?

It ensures consistent texture, creaminess, and structural stability, reducing errors and waste in high-volume operations.