Application of potting in the home appliances industry: Potting of Washing Machine Control Board / Computer Board?

The encapsulation of washing machine control boards (computer boards) is one of the most typical applications of automated potting machine, directly impacting the reliability, safety, and lifespan of the washing machine.

Below, I will elaborate on the application of Automatic Glue Potting Machine in the encapsulation of washing machine control boards from the perspectives of “why encapsulation is needed,” “what adhesive to use,” “how to perform encapsulation,” and “the benefits of encapsulation.”

Ι.Why is potting necessary for washing machine control boards? (Necessity) Washing machines operate in extremely harsh environments, posing multiple threats to the control board:

1.Water and moisture protection: The internal humidity of washing machines is extremely high, especially in top-loading washing machines. Condensation and accidental splashes can cause short circuits and component corrosion.

2.Corrosion protection: Detergents, fabric softeners, bleach, and other chemicals are corrosive; their vapors can corrode circuit boards and component leads.

3.Shock and loosening prevention: Washing machines generate severe vibrations during the spin-drying process. Prolonged vibration can lead to solder joint cracking and component loosening.

4.Heat dissipation and insulation:Power devices on the control board (such as SCRs) generate heat during operation. Potting compound helps dissipate heat and provides excellent electrical insulation, preventing high-voltage creepage.

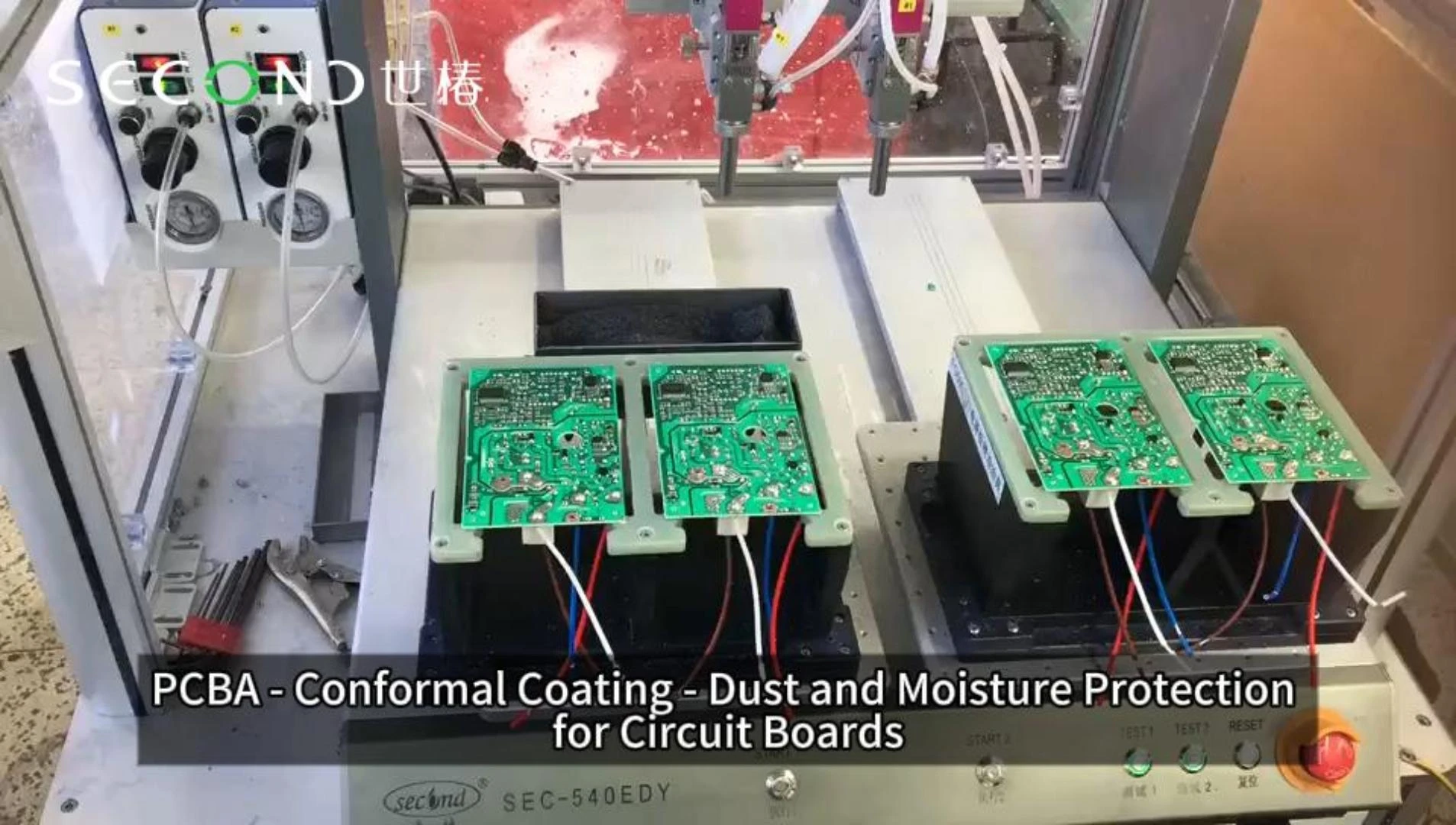

Second Intelligent has played an important role in theresearch, development, manufacturing, pre-sales and after-sales services of fluid dispensing robot, potting and coating solutions which range from various types of automatic fluid dispensing, potting, two-component potting machines and coating machines with desktop, free-standing, inline or cobot combined systems, and widely used in global electrical, electronics, home appliances, automobile, telecom, pharmaceutical, automotive electronics, semiconductor, aerospace, LED and more.

The encapsulation of washing machine control boards (computer boards) is one of the most typical applications of automated potting machine, directly impacting the reliability, safety, and lifespan of the washing machine.

Below, I will elaborate on the application of Automatic Glue Potting Machine in the encapsulation of washing machine control boards from the perspectives of “why encapsulation is needed,” “what adhesive to use,” “how to perform encapsulation,” and “the benefits of encapsulation.”

Ι.Why is potting necessary for washing machine control boards? (Necessity) Washing machines operate in extremely harsh environments, posing multiple threats to the control board:

1.Water and moisture protection: The internal humidity of washing machines is extremely high, especially in top-loading washing machines. Condensation and accidental splashes can cause short circuits and component corrosion.

2.Corrosion protection: Detergents, fabric softeners, bleach, and other chemicals are corrosive; their vapors can corrode circuit boards and component leads.

3.Shock and loosening prevention: Washing machines generate severe vibrations during the spin-drying process. Prolonged vibration can lead to solder joint cracking and component loosening.

4.Heat dissipation and insulation:Power devices on the control board (such as SCRs) generate heat during operation. Potting compound helps dissipate heat and provides excellent electrical insulation, preventing high-voltage creepage.

Second Intelligent has played an important role in theresearch, development, manufacturing, pre-sales and after-sales services of fluid dispensing robot, potting and coating solutions which range from various types of automatic fluid dispensing, potting, two-component potting machines and coating machines with desktop, free-standing, inline or cobot combined systems, and widely used in global electrical, electronics, home appliances, automobile, telecom, pharmaceutical, automotive electronics, semiconductor, aerospace, LED and more.

Application of potting in the home appliances industry: Potting of Washing Machine Control Board / Computer Board? The encapsulation of washing machine control boards (computer boards) is one of the most typical applications of automated potting machine, directly impacting the reliability, safety, and lifespan of the washing machine. Below, I will elaborate on the application of Automatic Glue Potting Machine in the encapsulation of washing machine control boards from the perspectives of “why encapsulation is needed,” “what adhesive to use,” “how to perform encapsulation,” and “the benefits of encapsulation.” Ι.Why is potting necessary for washing machine control boards? (Necessity) Washing machines operate in extremely harsh environments, posing multiple threats to the control board: 1.Water and moisture protection: The internal humidity of washing machines is extremely high, especially in top-loading washing machines. Condensation and accidental splashes can cause short circuits and component corrosion. 2.Corrosion protection: Detergents, fabric softeners, bleach, and other chemicals are corrosive; their vapors can corrode circuit boards and component leads. 3.Shock and loosening prevention: Washing machines generate severe vibrations during the spin-drying process. Prolonged vibration can lead to solder joint cracking and component loosening. 4.Heat dissipation and insulation:Power devices on the control board (such as SCRs) generate heat during operation. Potting compound helps dissipate heat and provides excellent electrical insulation, preventing high-voltage creepage. Second Intelligent has played an important role in theresearch, development, manufacturing, pre-sales and after-sales services of fluid dispensing robot, potting and coating solutions which range from various types of automatic fluid dispensing, potting, two-component potting machines and coating machines with desktop, free-standing, inline or cobot combined systems, and widely used in global electrical, electronics, home appliances, automobile, telecom, pharmaceutical, automotive electronics, semiconductor, aerospace, LED and more.